Full-automatic charge-discharge intelligent data acquisition system of accumulator

A technology of intelligent data acquisition and data acquisition circuit, which is applied in the directions of secondary battery charging/discharging, secondary battery repair/maintenance, electrical measurement, etc., can solve problems such as large time differences, large product quality differences, and large errors, and achieve High work efficiency, low labor intensity, accurate and reliable matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the present invention in further detail in conjunction with the drawings and specific embodiments:

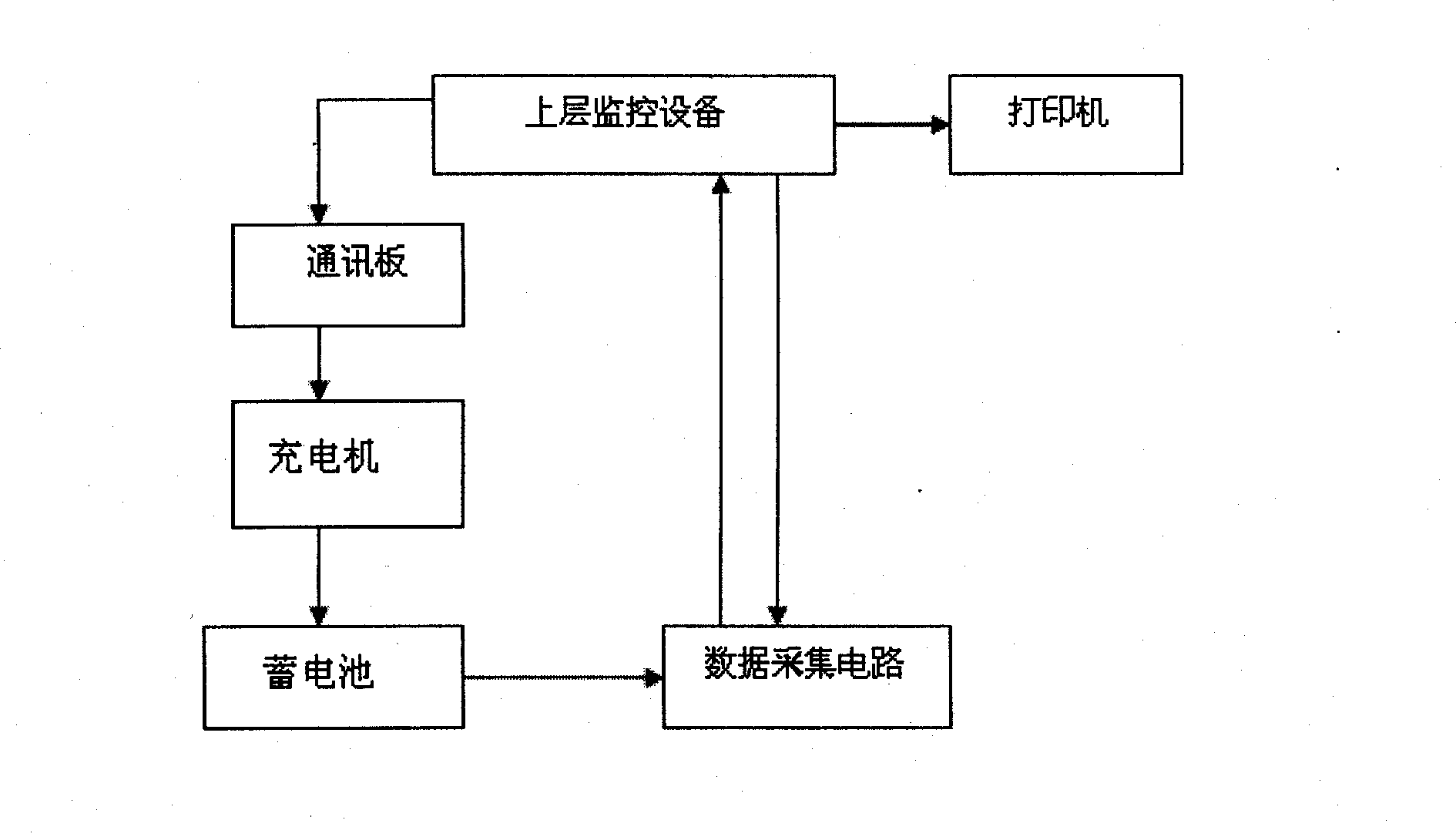

[0021] Such as figure 1 As shown, the system of the present invention includes a number of storage batteries placed on a charging rack, at least one charger, at least one data acquisition circuit, and upper-level monitoring equipment. One output of the upper-level monitoring equipment is connected to the input of the charger and the output of the charger. Connect the positive and negative ends of each battery, and connect the positive and negative electrodes of each battery as the voltage signal output to the input of the data acquisition circuit, and the input and output of the data acquisition circuit are respectively connected to the corresponding input and output of the upper monitoring equipment.

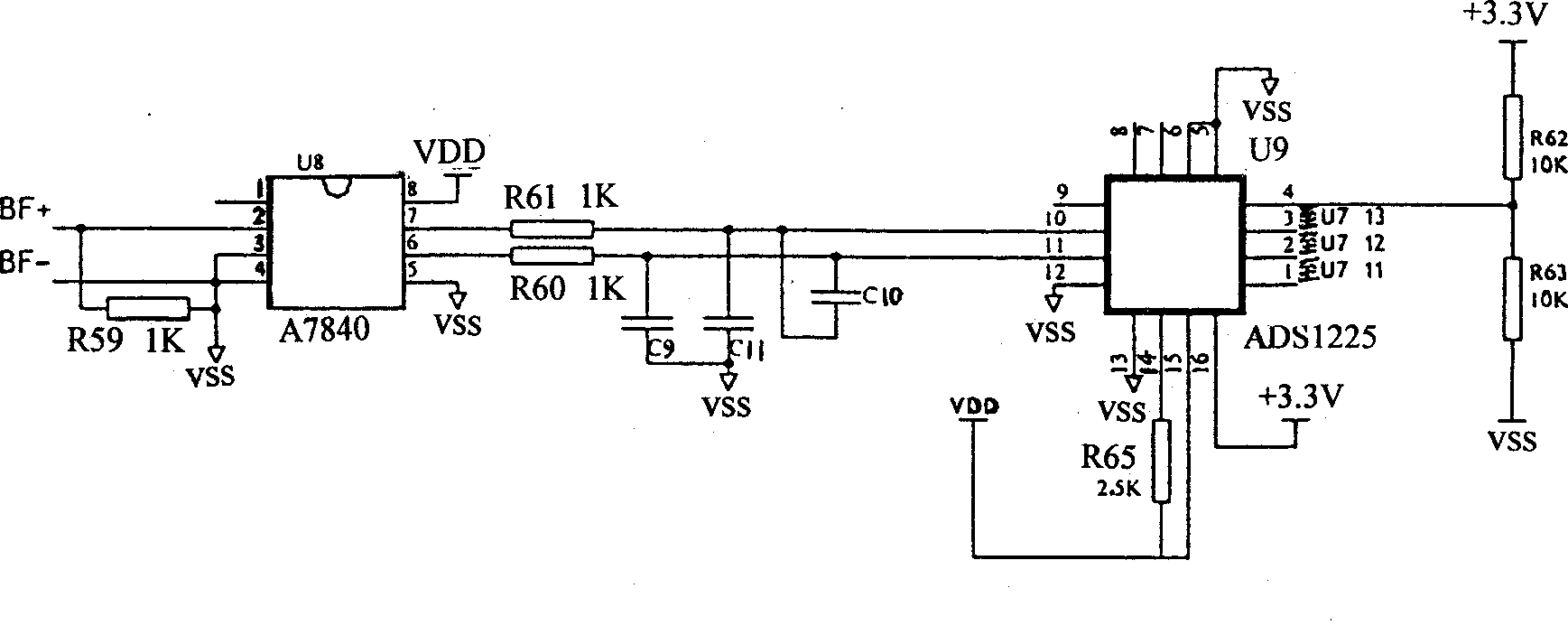

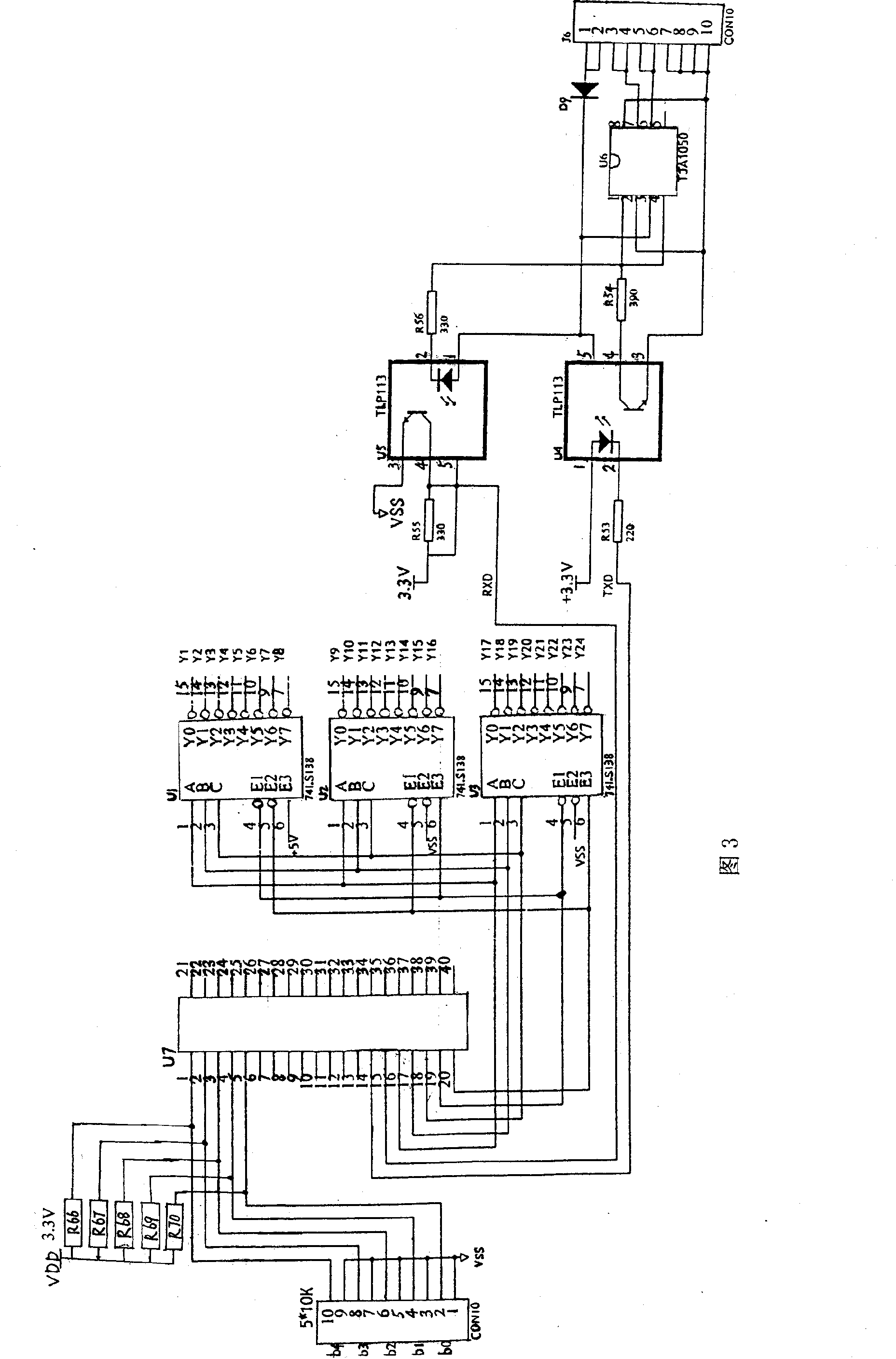

[0022] Such as figure 2 , As shown in Figure 3, the data acquisition circuit includes AD conversion circuit U9 (model ADS1255), single-chip circuit U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com