Cable clamper

A technology of cable clamps and splints, which is applied in the field of power circuits, can solve the problems of small cable contact area, cable mechanical damage, and high cable pressure, and achieve the effects of reducing cable damage, ensuring cable protection, and increasing the clamping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

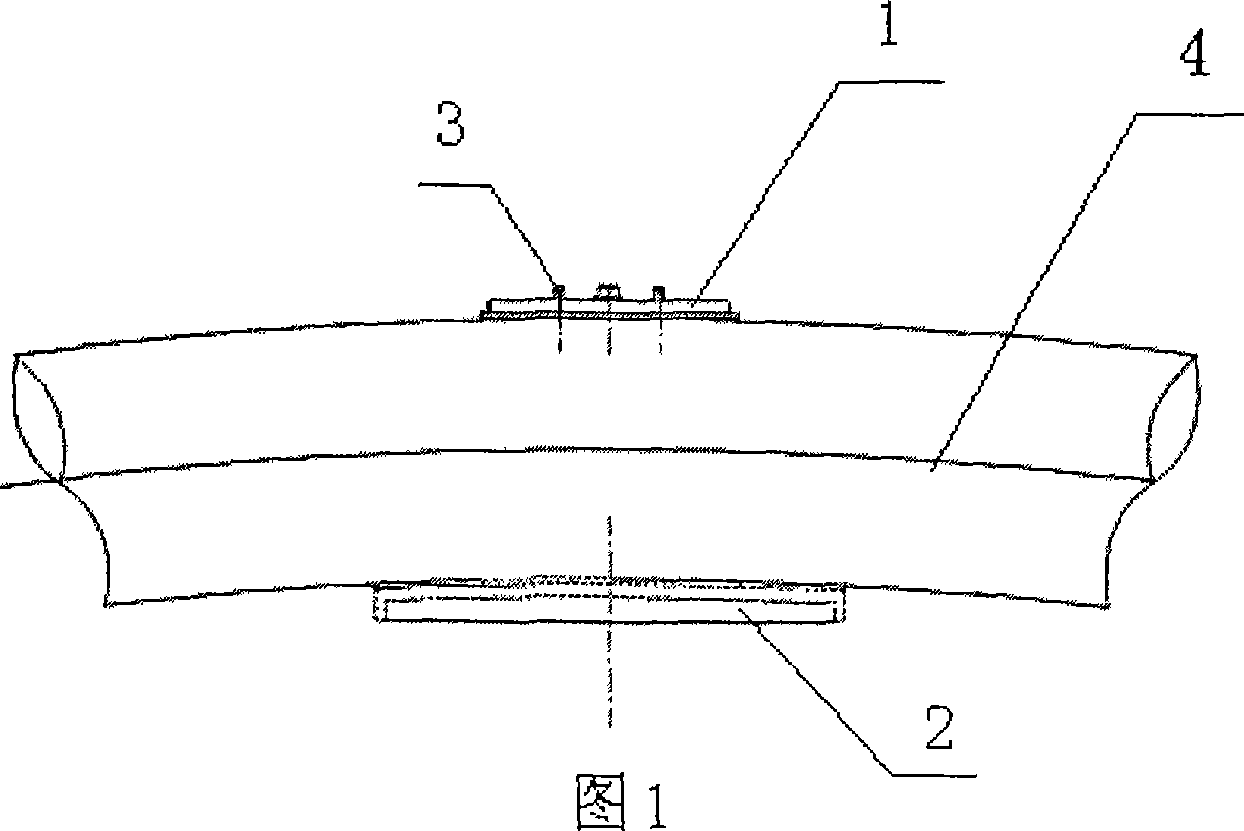

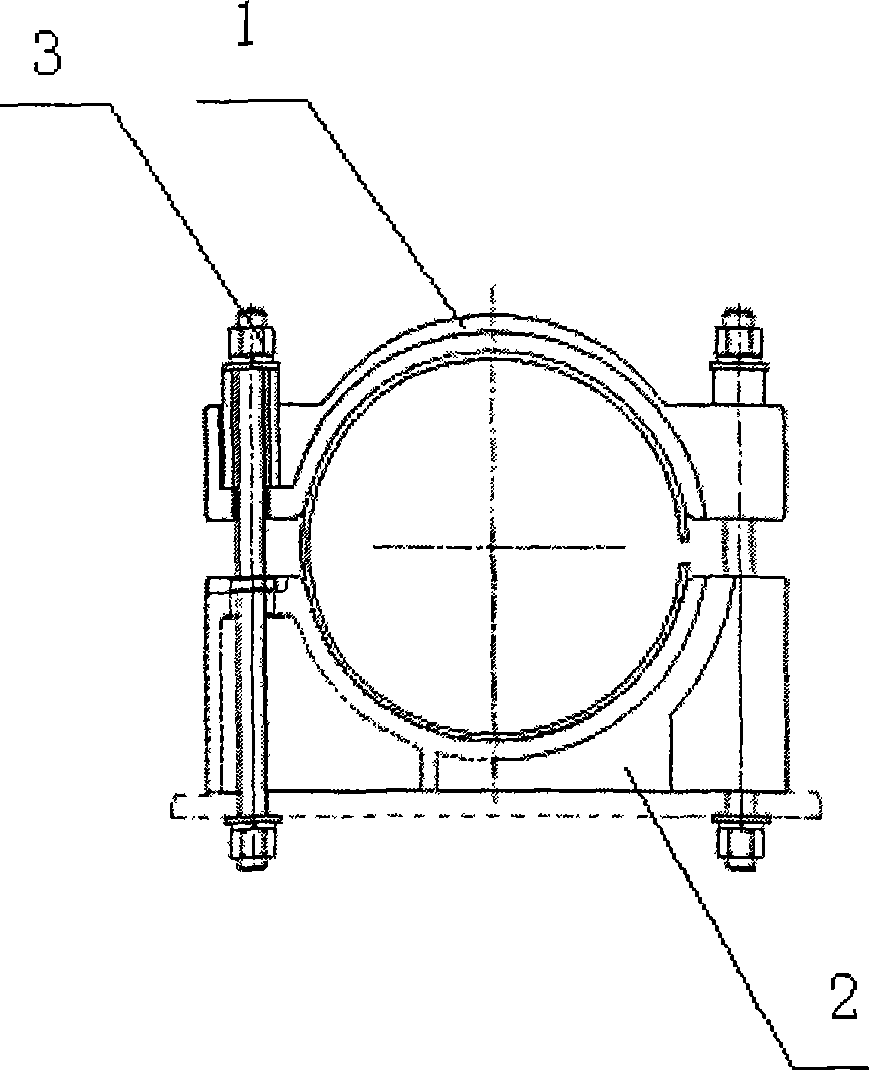

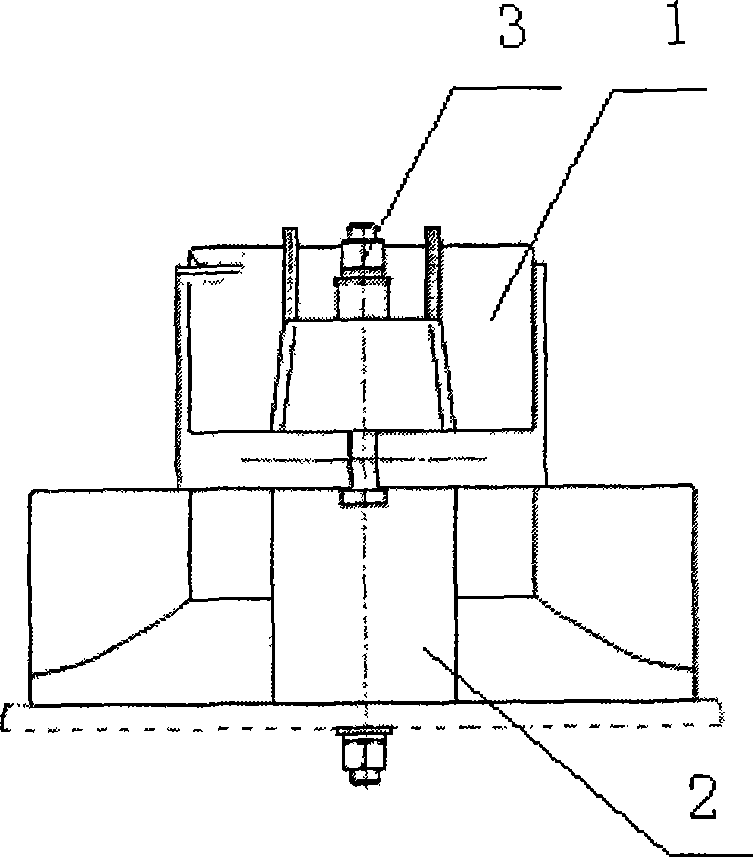

[0021] A cable clamp includes two semicircular splints (ie, the upper splint and the lower splint in the figure). The cross-sectional shape of the splints is part of the same ring, and they are connected to each other to form a hollow where cables can be placed. One of the two splints is longer than the other. The axial section of the longer splint (lower splint) is arc-shaped. The position of the shorter splint (upper splint) corresponds to the vault position of the longer curved splint (lower splint). The back of the curved splint is opposite to the shorter splint. The inner surface of the splint is provided with a protective pad. The two splints are connected by bolts.

[0022] In this example, the clamp material is preferably aluminum alloy. Liners or protective pads can be rubber, plastic, lead plates and wooden washers, and plastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com