Side blowing type fan

A side-blown fan and air inlet technology, which is applied to non-variable-capacity pumps, non-displacement pumps, components of pumping devices for elastic fluids, etc. The effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

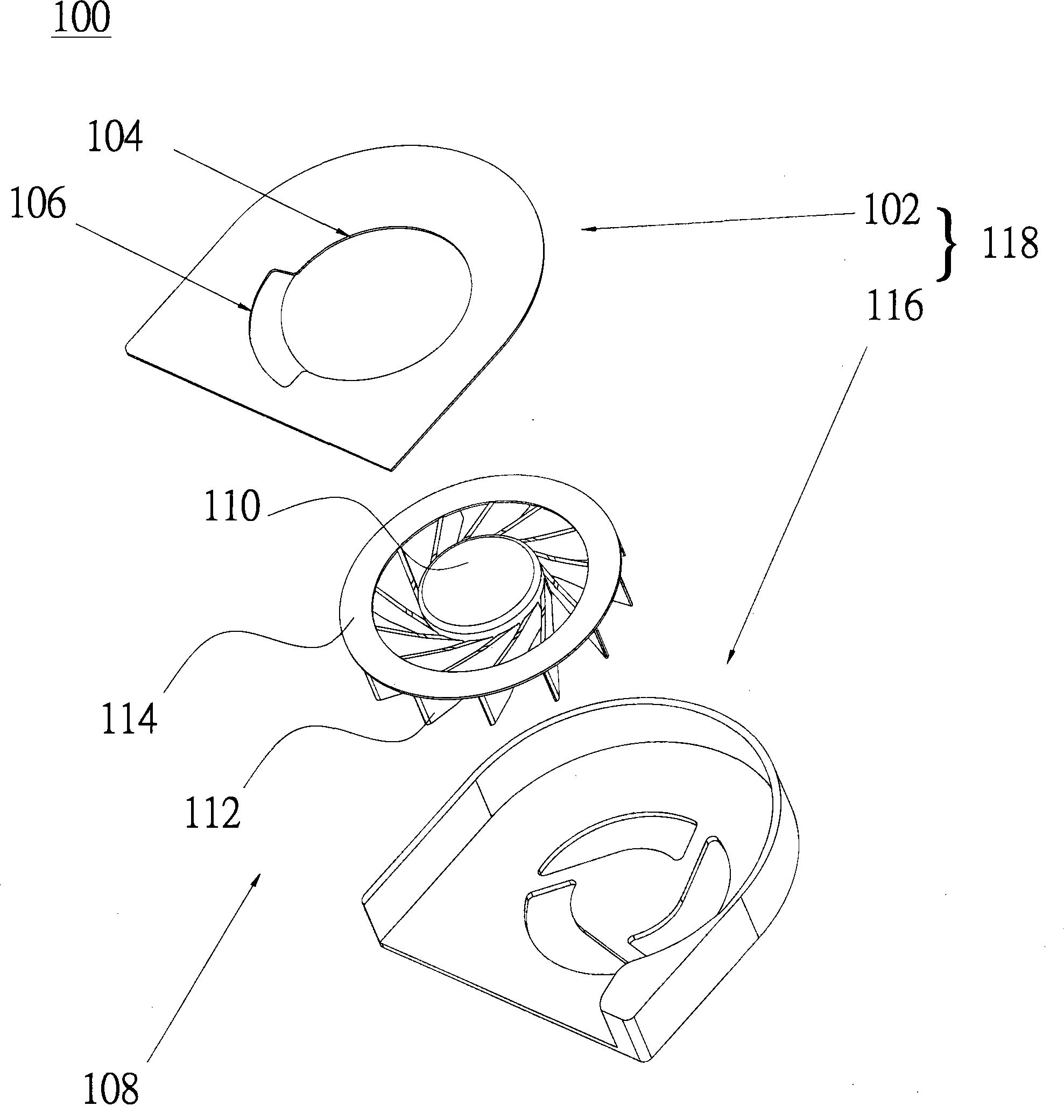

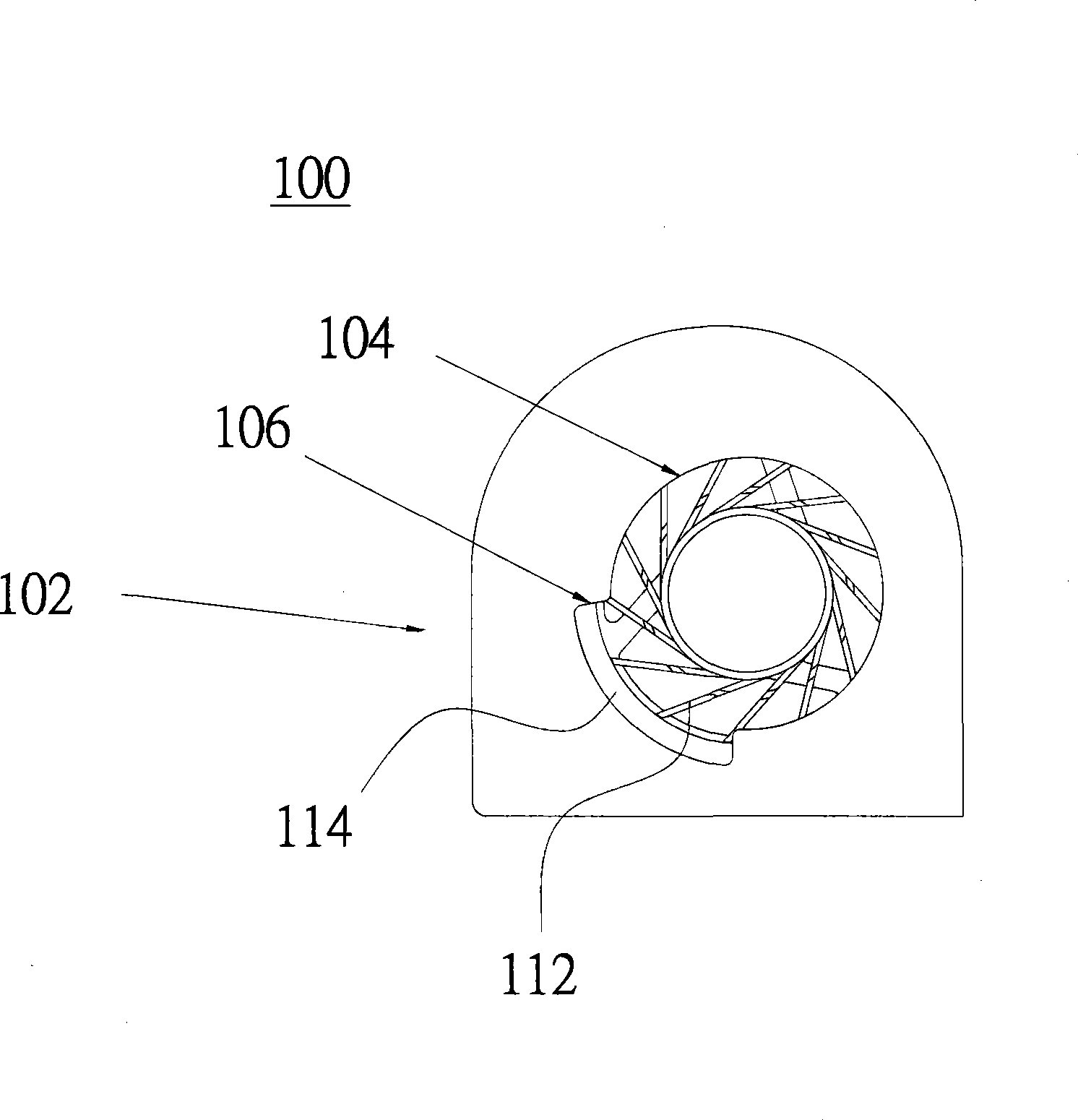

[0023] Please refer to figure 1 and figure 2 , The side blowing fan 100 of the present invention includes a first housing 102 , a second housing 116 and an impeller 108 . The side blowing fan may be a blower fan.

[0024] The first housing 102 has a main air inlet 104 and at least one auxiliary air inlet 106 . The first housing 102 and the second housing 116 are correspondingly connected to form a housing 118 to form an accommodating space. The shape of the main air inlet 104 can be circular, oval, polygonal or irregular. Preferably, the main air inlet 104 is coaxial with the impeller 108 .

[0025] The auxiliary air inlet 106 can extend outward from the edge of the main air inlet 104 , or can be independent of the main air inlet 104 . The shape of the auxiliary air inlet 106 can be circular, fan-shaped, polygonal, circular hole, elliptical hole or sausage-shaped hole. The number of auxiliary air inlets 106 can be one, or two or more.

[0026] The impeller 108 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com