Tire mounting device of automatic unstacking type tire test machine

A testing machine and tire technology, applied in the direction of automobile tire testing, etc., can solve the problems of large manual labor, on-site chaos, manual destacking, etc., and achieve the effect of reducing labor intensity, avoiding chaotic placement, and reducing labor occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

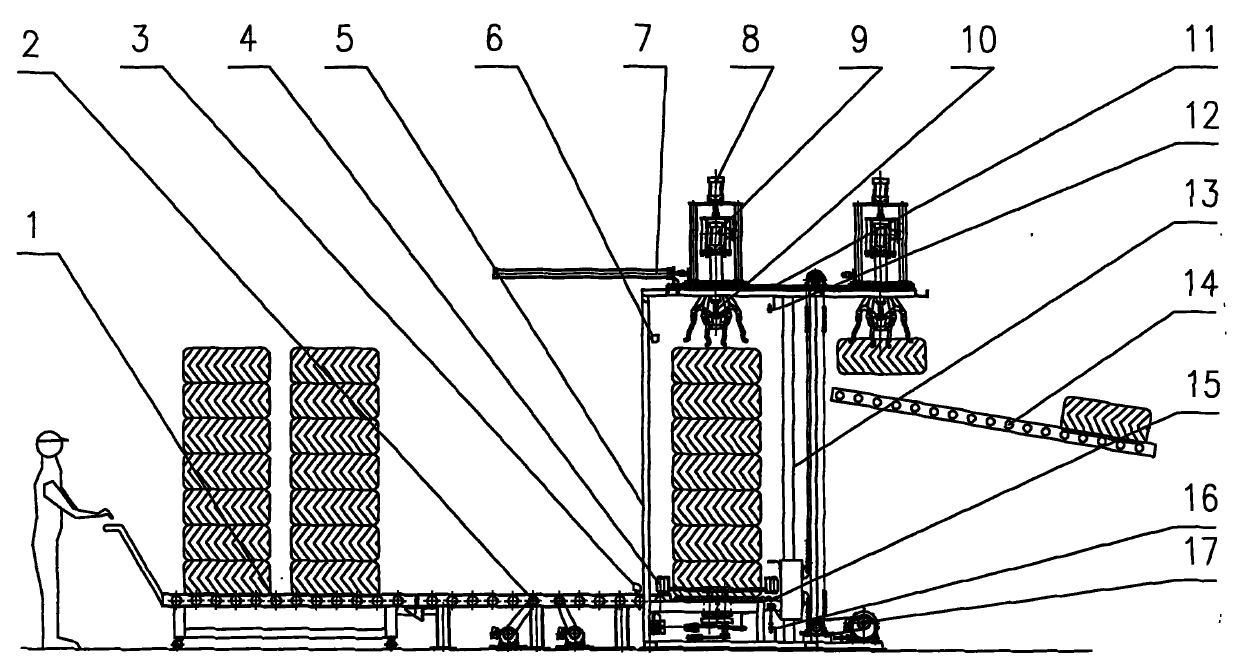

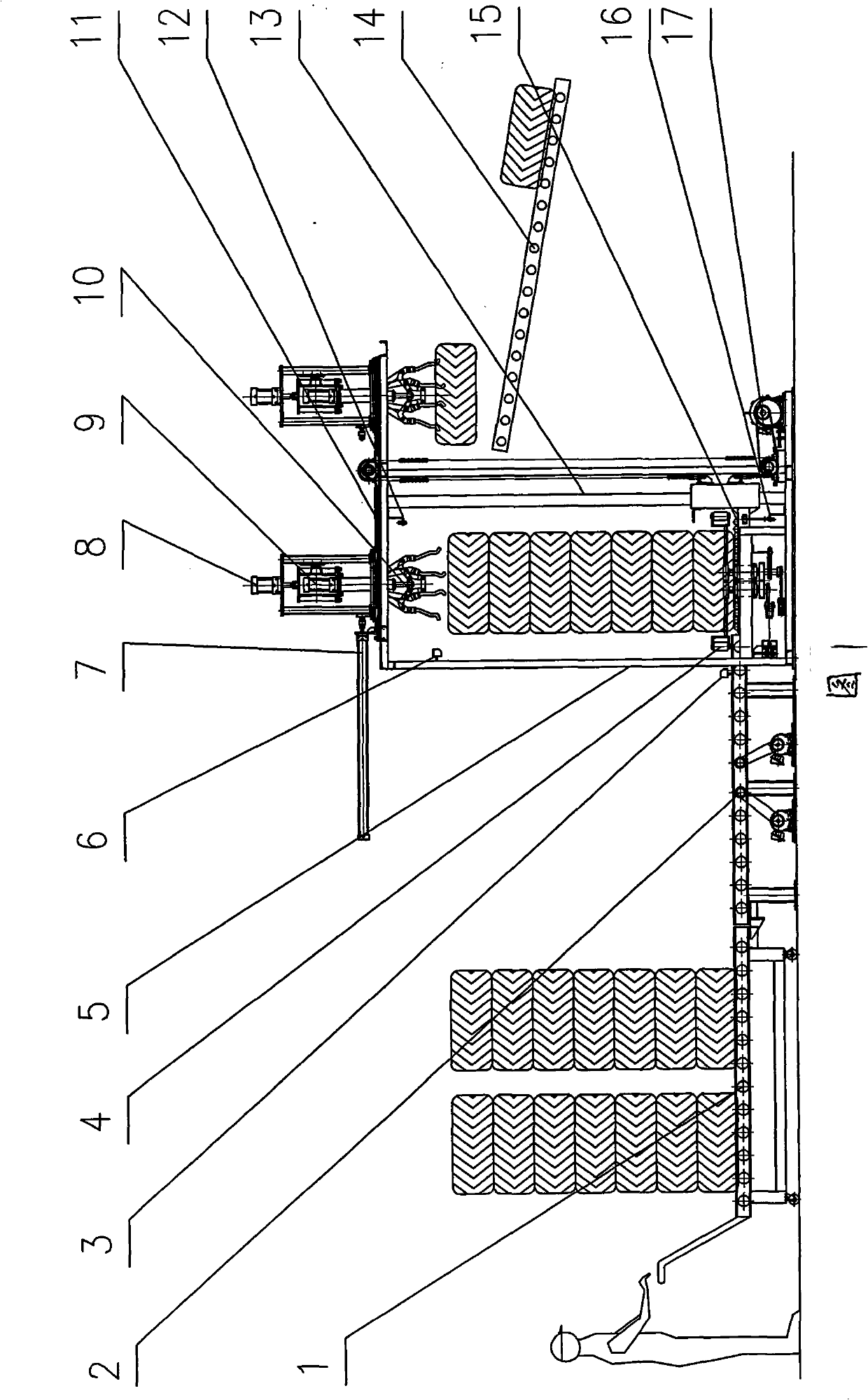

[0012] like figure 1 As shown, the present invention is made up of special trolley 1 and automatic unstacker two parts, and wherein automatic unstacker mainly consists of: storage tire roller table 2, centering device 4, frame 5, manipulator 10, manipulator translational cylinder 7, Manipulator opening and closing cylinder 9, manipulator lifting cylinder 8, manipulator platform guide rail 11, lifting ball table 15, lifting guide rod 13, lifting drive device 17, free roller table 14, tire stack detection switch 6, platform upper limit switch 12 and platform lower limit Switch 16, tire storage detection switch 3, electric control system, etc. The tire storage roller table 2 is driven by a motor located below the tire storage roller table 2, the end of the tire storage roller table 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com