Shape inspection apparatus, and shape inspection method

A technology for inspecting devices and three-dimensional shapes, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as selection and designation errors, omissions of shape constituent elements, etc., to achieve rapid judgment processing, shorten judgment time, eliminate adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, a shape inspection apparatus, a shape inspection method, and a shape inspection program according to the present invention will be described with reference to the accompanying drawings.

[0033] Here, the determination as to whether the rib structure portion satisfies the shape condition is exemplarily described. Here, the rib structure portion is a convex-shaped portion in a product member having a three-dimensional shape.

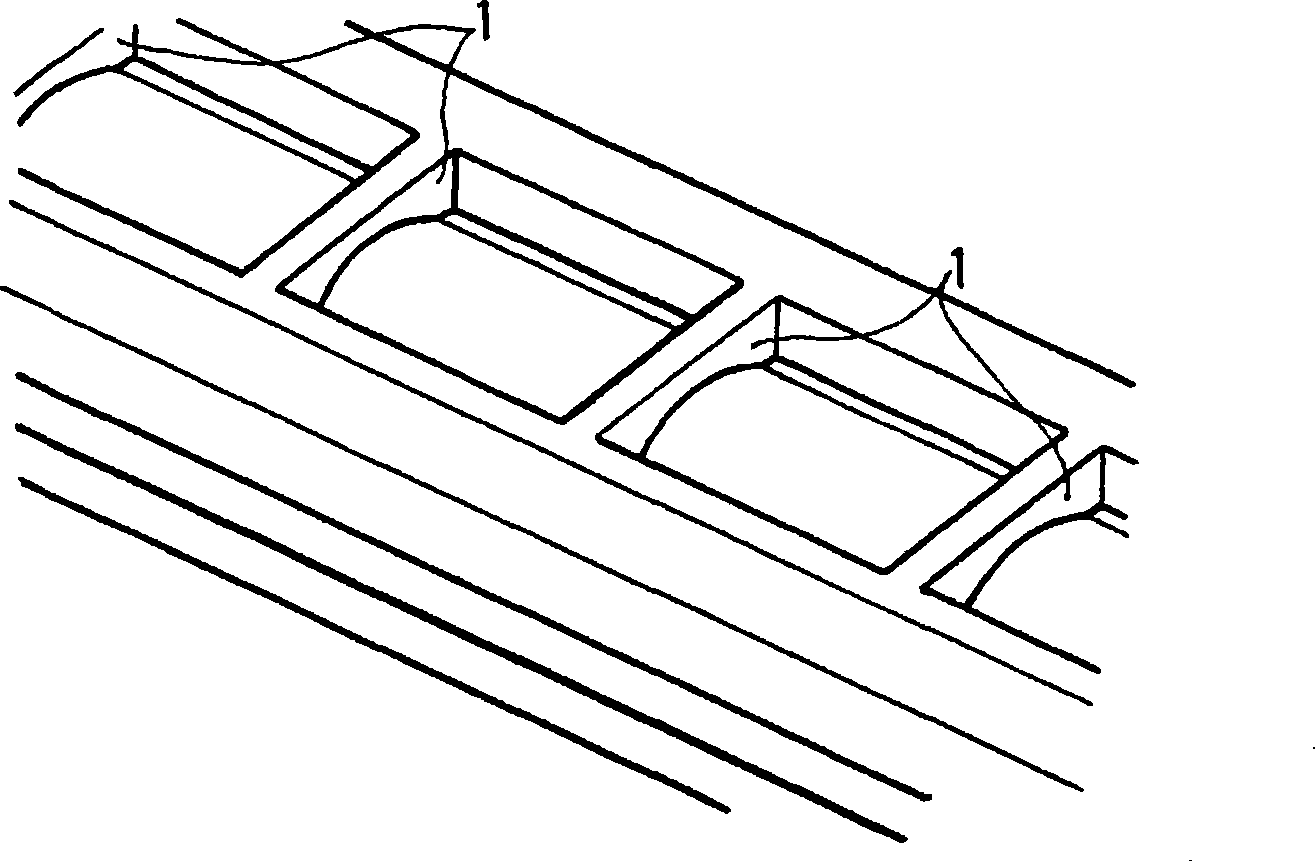

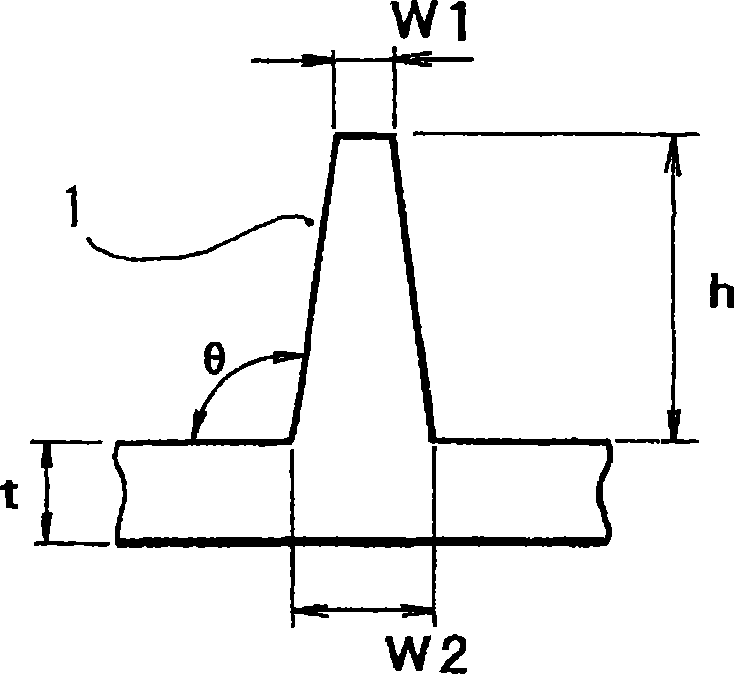

[0034] Figure 1A and Figure 1B is an explanatory diagram showing a rib structure portion as a specific example of a shape portion subjected to determination processing.

[0035] like Figure 1A As shown, a product member having a three-dimensional shape generally has a rib structure portion (hereinafter simply referred to as "rib") 1, which is a convex shape portion for preventing deflection of the member or ensuring strength (rigidity) of the member.

[0036] However, when the rib 1 has an excessively large height or thickness, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com