Adaptive multivariate fault detection

A multi-variable statistical and error technology, applied in the field of error detection, can solve problems such as inaccurate statistical values, false alarms and failures, and failure to provide coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

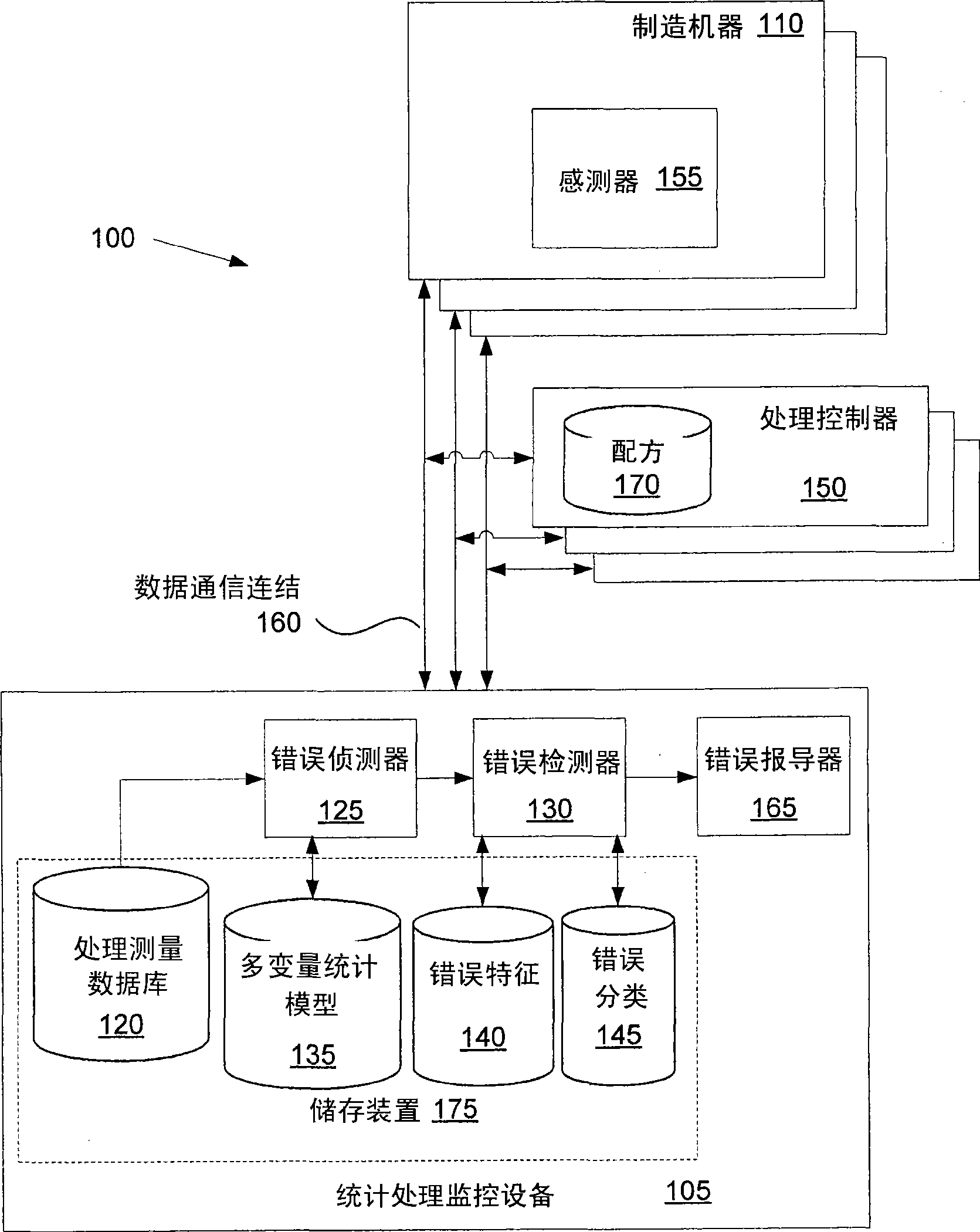

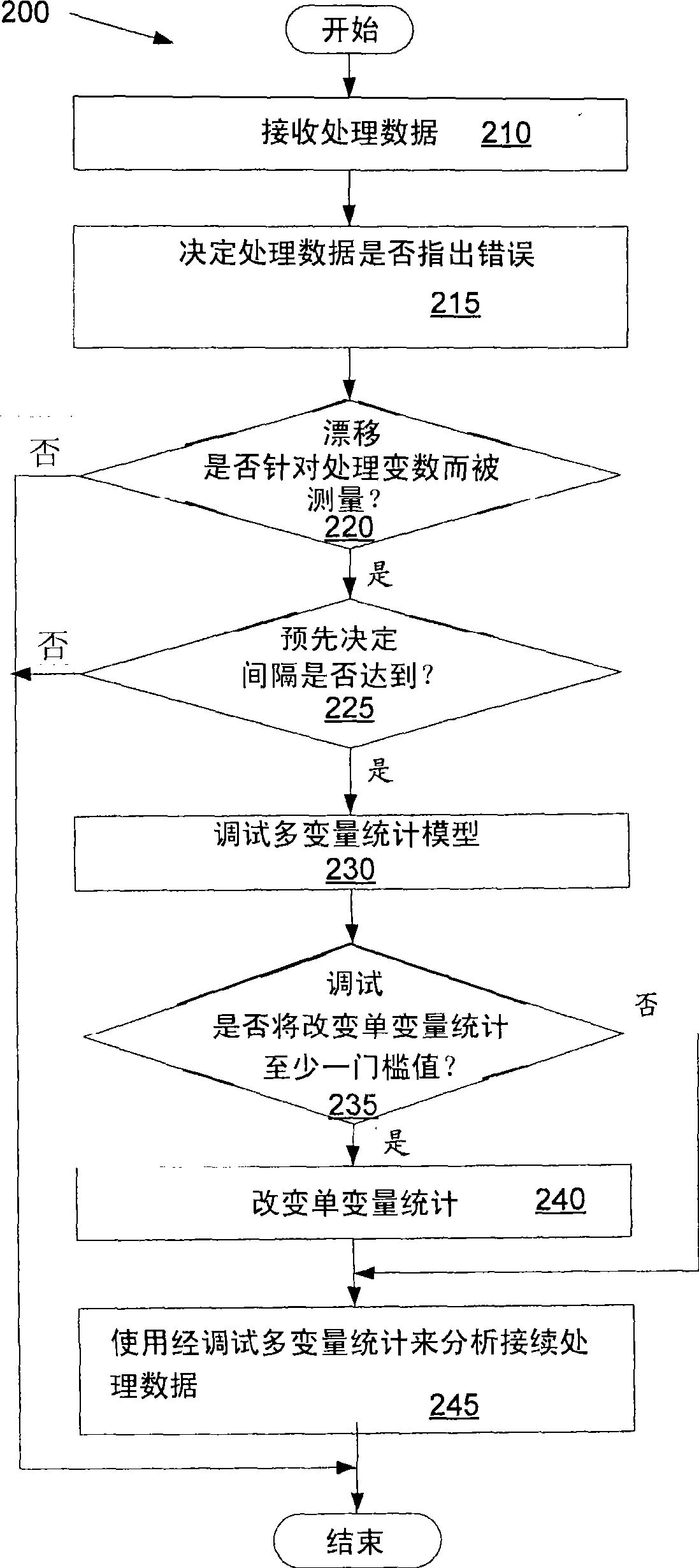

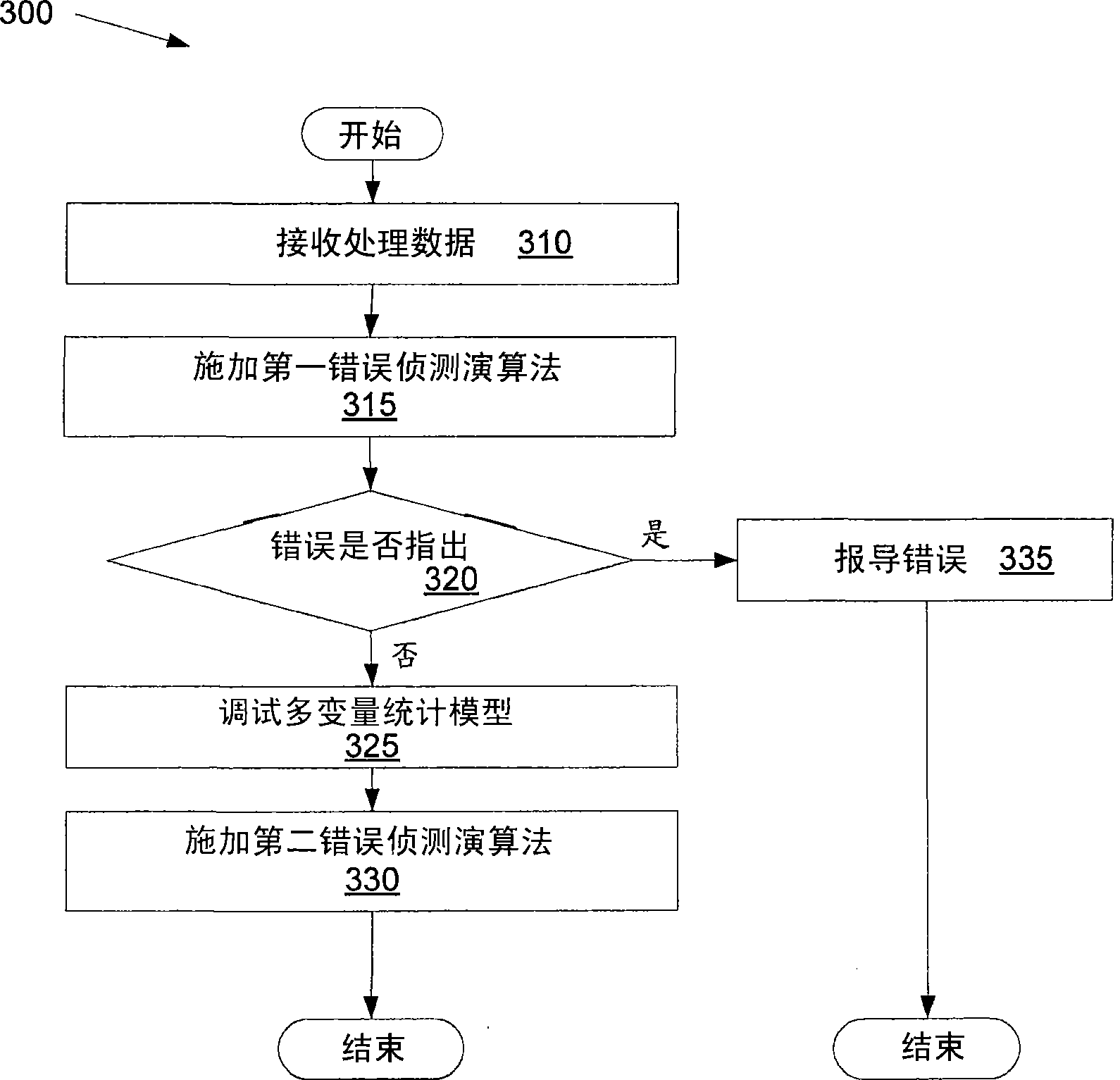

[0068] Described herein is a method and apparatus for detecting errors. In one embodiment, process data comprising a plurality of process variables is received. Examples of process variables include temperature, pressure, silane flow, and the like. One or more multivariate statistical models are adapted based on the processed data. Adapting can include applying a change to at least one univariate statistic of the multivariate statistic module if the change will not exceed a threshold. In an embodiment, adaptation is performed over predetermined intervals based on a measured drift of one or more process variables. The adapted multivariate statistical model can then be used to analyze subsequent processing data for the detection of each error.

[0069] In the following description, numerous details are set forth. However, it will be apparent to those skilled in the art that the present invention may be practiced without the following specific details. In certain instances, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com