Electrolytic aluminum whole-process monitoring and fault diagnosis system based on multivariate statistic method

A fault diagnosis system and multivariate statistical technology, applied in the field of electrolytic aluminum process monitoring and fault diagnosis, to prevent pipeline leakage and prevent disease slots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Combined with the accompanying drawings Figure 1-Figure 9 The present invention is further described;

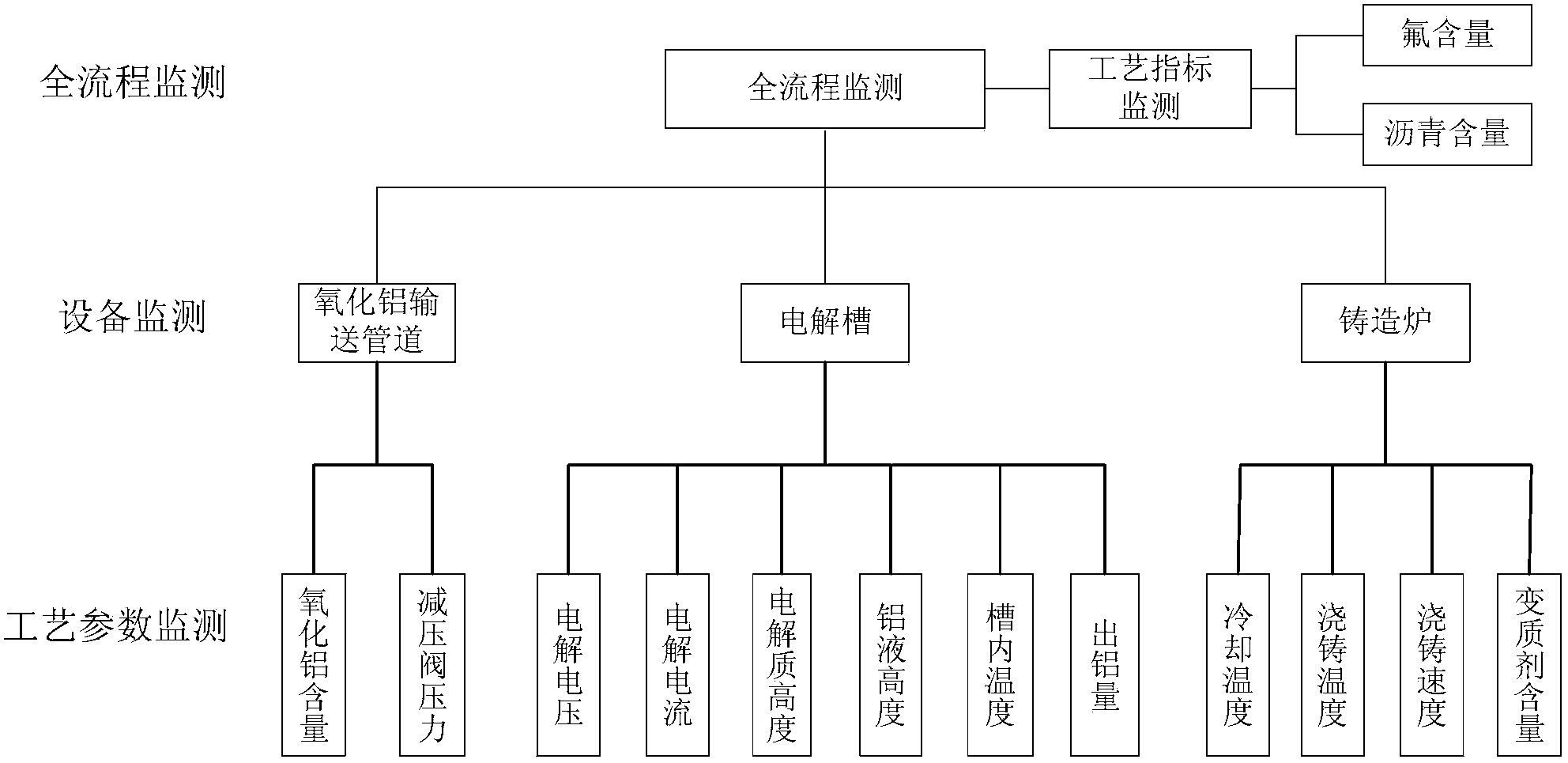

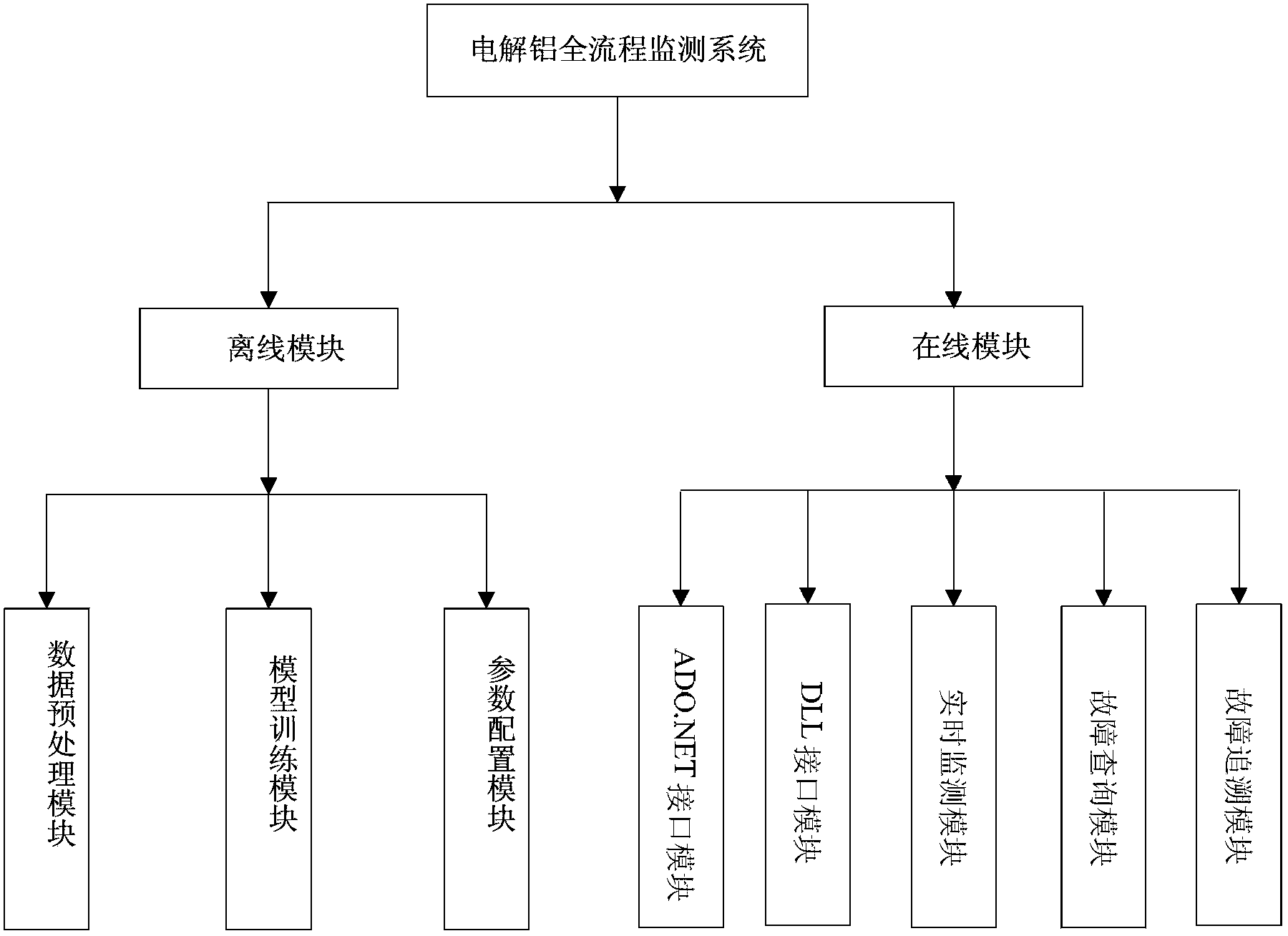

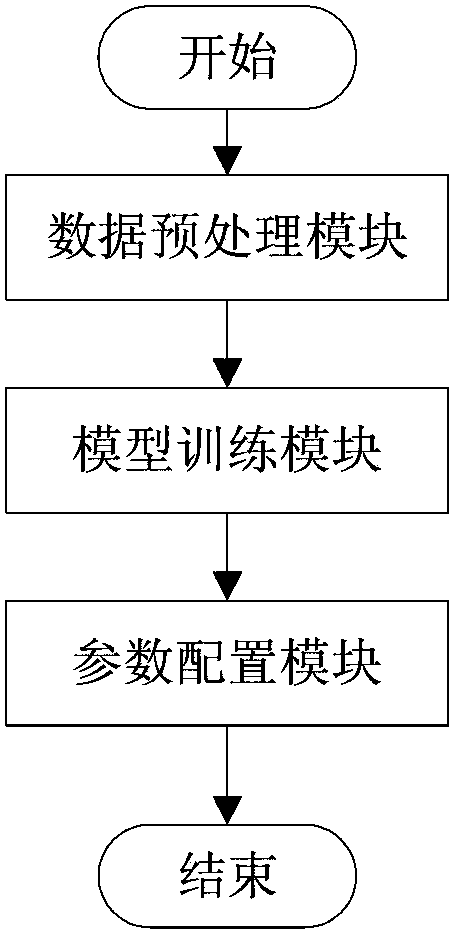

[0090] A whole-process monitoring and fault diagnosis system for electrolytic aluminum based on multivariate statistical methods. The system is divided into three layers. The bottom layer monitors key process parameters, the middle layer monitors equipment operation in the electrolytic aluminum process, and the top layer monitors the entire process. Comprehensive monitoring (including key process indicators);

[0091] The system monitors the top layer, middle layer, and bottom layer respectively, and analyzes the monitoring results of the three layers to determine the T value in each layer that reflects the variable amplitude in the PCA model. 2 Statistics, S reflecting the magnitude of variables in the ICA model 2 Whether the statistics and squared prediction error SPE statistics exceed the limit, so as to ensure the pertinence of monitoring and the accuracy of mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com