Electric power generator, method for generating electric power, and motor

An electric motor and generator technology, applied in electrical components, electromechanical devices, etc., can solve the problem of incremental efficiency exceeding 1, and achieve the effects of simple structure, reducing back torque, and increasing incremental efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

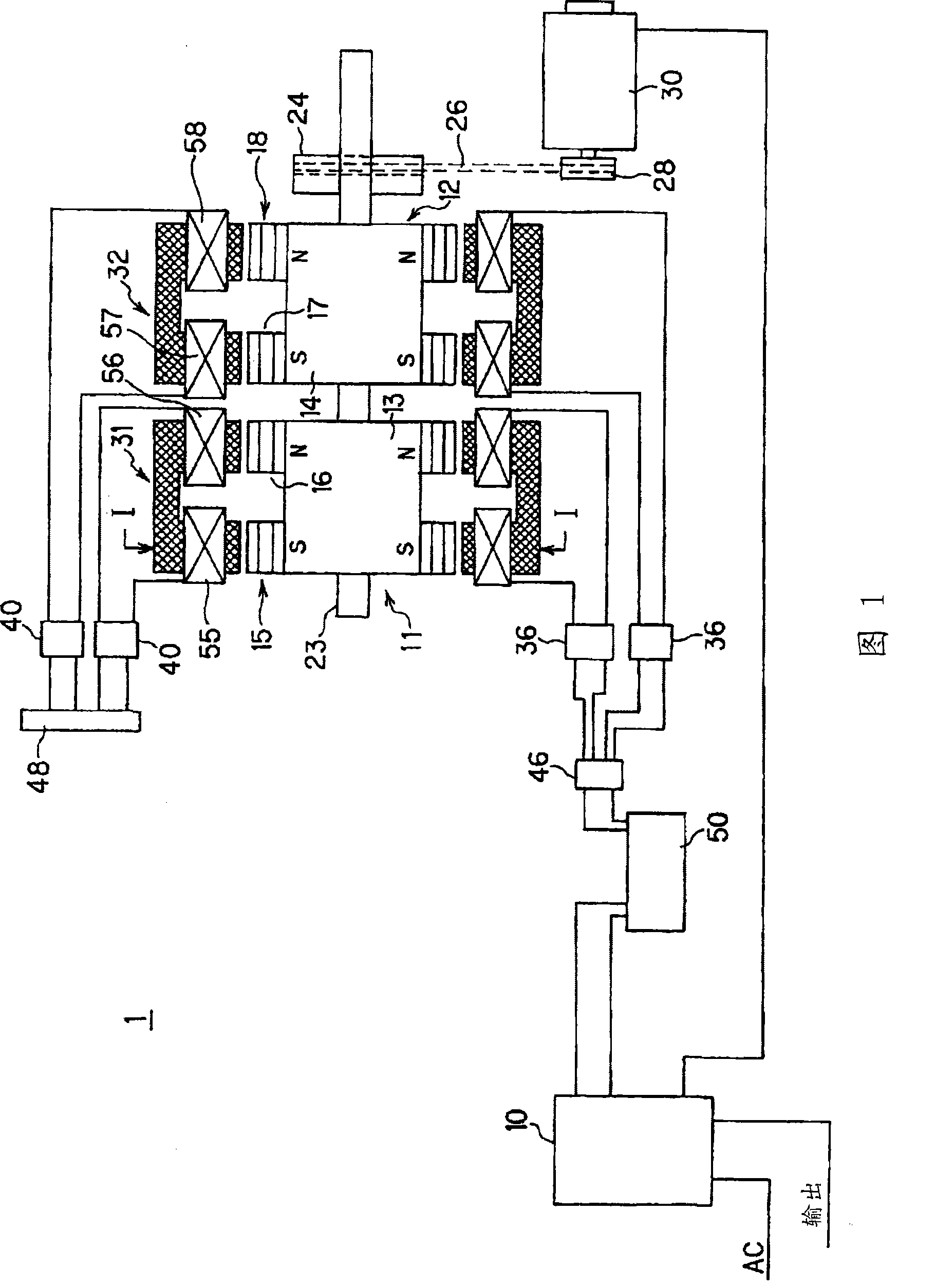

[0054] FIG. 1 shows the structure of a generator 1 according to an embodiment of the present invention. As shown in this figure, the generator 1 includes: a control device 10 for controlling the power generation program, a first rotor 11 and a second rotor 12, and a first stator 31 and a second stator arranged around the rotors 11 and 12 respectively. 32. A DC motor 30, an electric double layer capacitor 50 for storing the electric energy output by the stator.

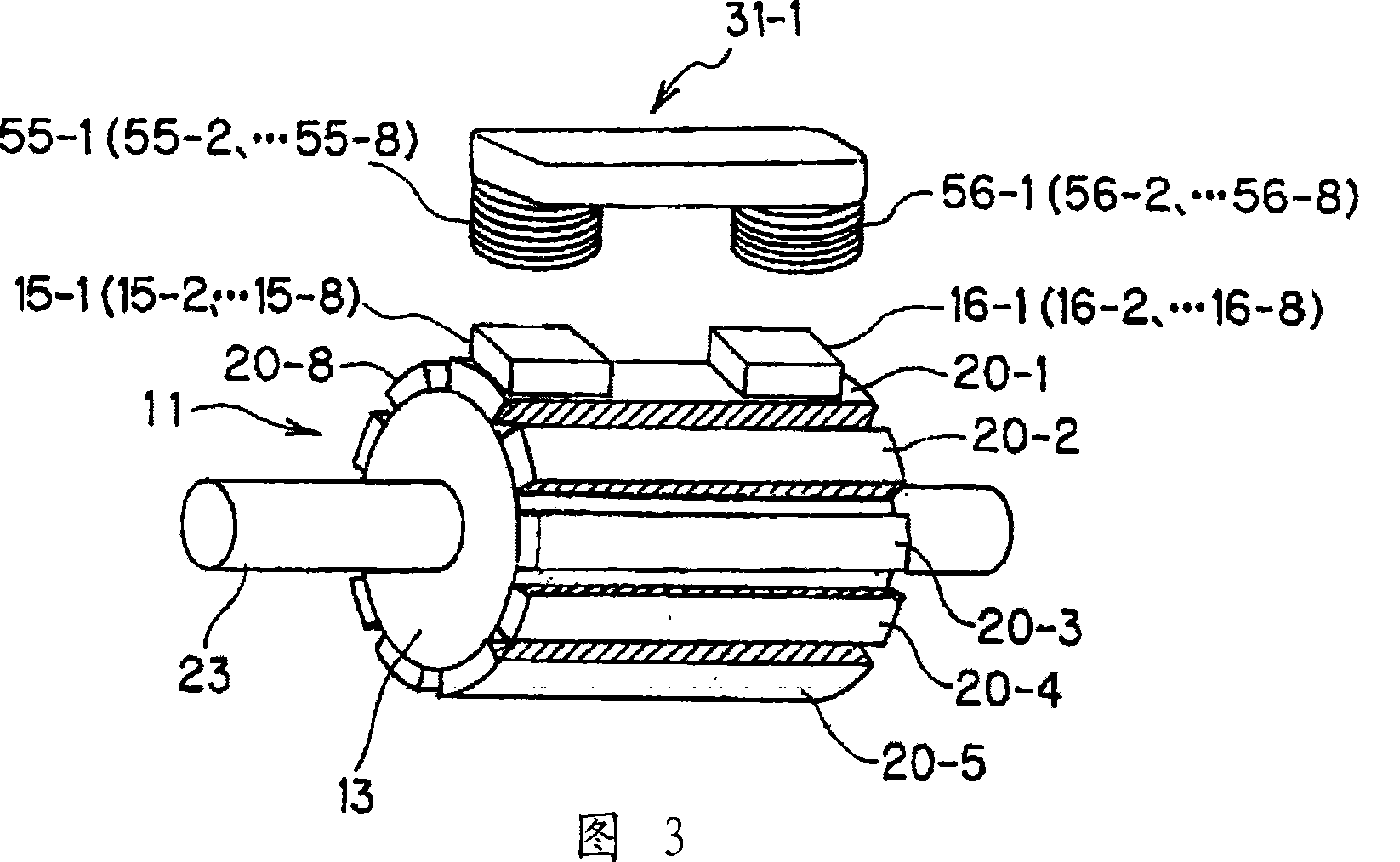

[0055] The first rotor 11 and the second rotor 12 are rotatable together using a common main shaft 23 as a rotation axis. A pulley 24 is installed on the main shaft 23 , and a belt 26 is arranged between the pulley 24 and the pulley 28 installed on the output shaft of the DC motor 30 . Therefore, the first rotor 11 and the second rotor 12 are rotated together by the rotation of the DC motor 30 .

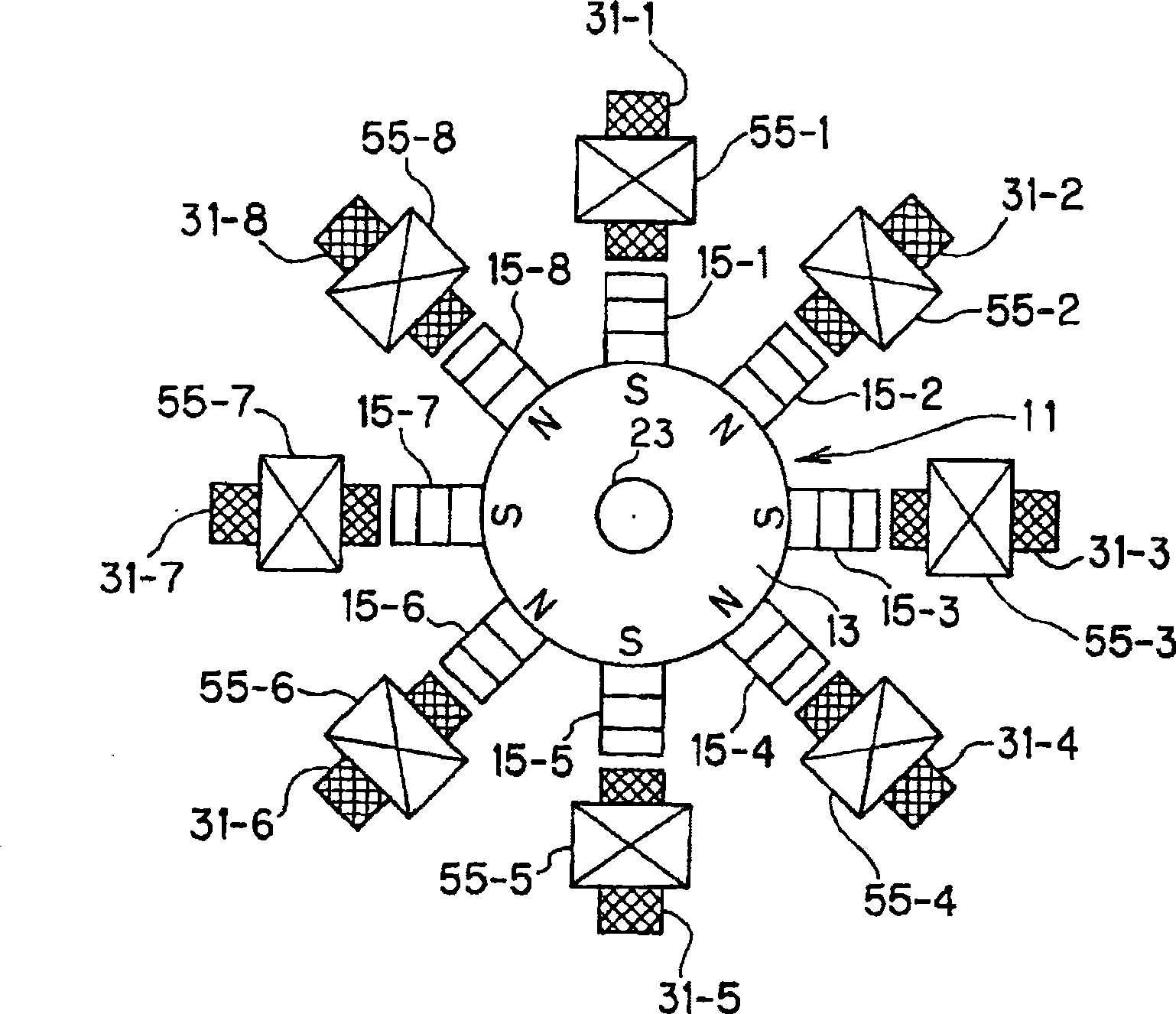

[0056] The first rotor 11 is axially equipped with two rows of magnet rows side by side: a first magnet row 15 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com