Automatic vertical type backwashing device

A backwashing and vertical technology, applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problems of high cost, difficult removal, poor filtration effect, etc., achieving low cost, wide adaptability, The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

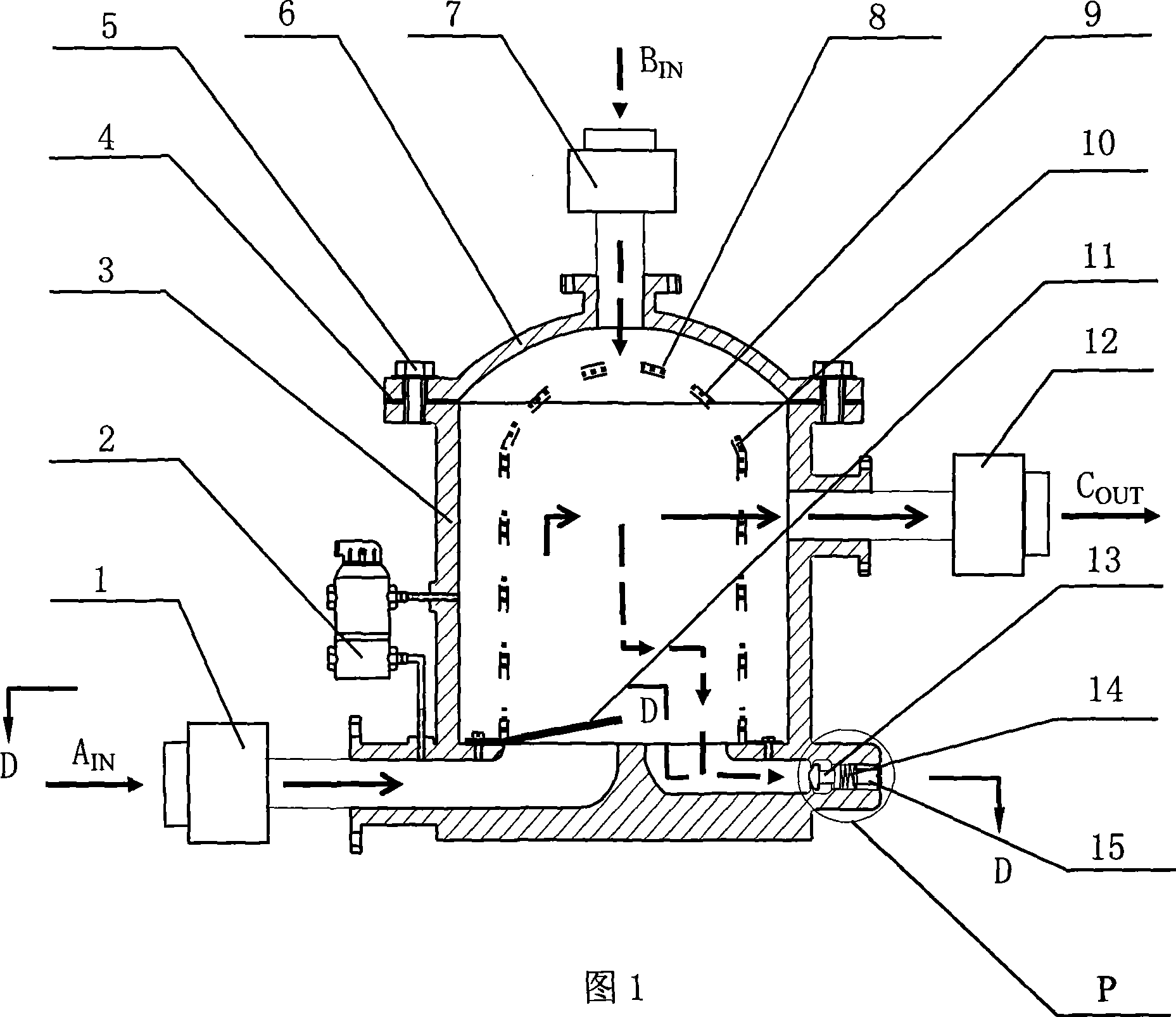

[0012] Below in conjunction with embodiment and accompanying drawing thereof, the present invention will be described in further detail:

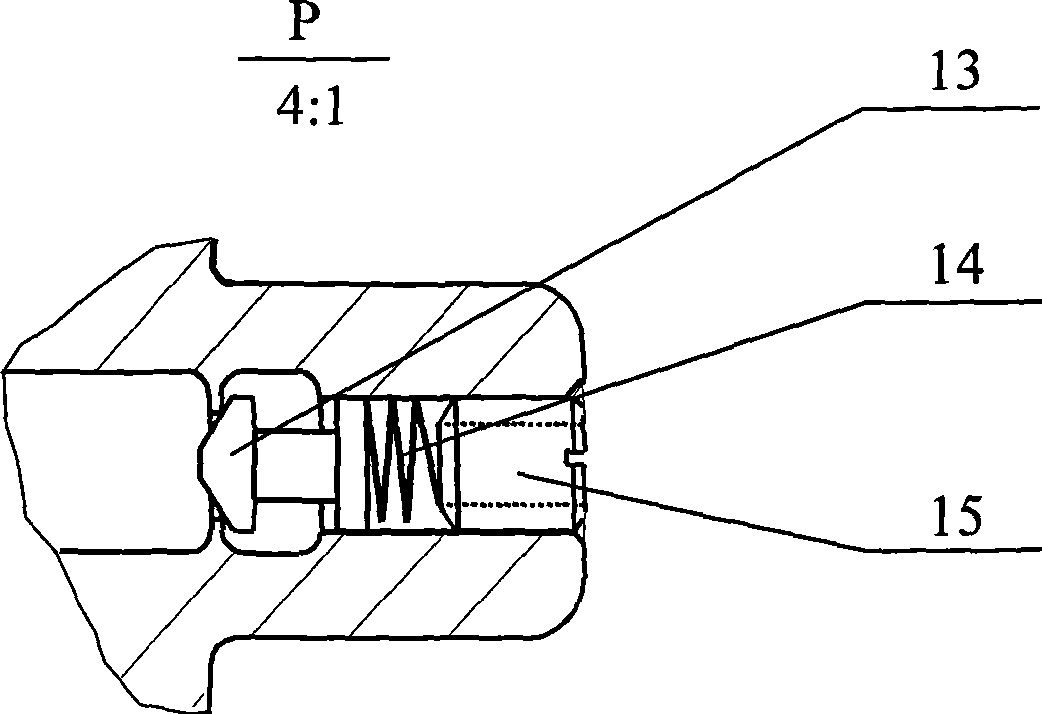

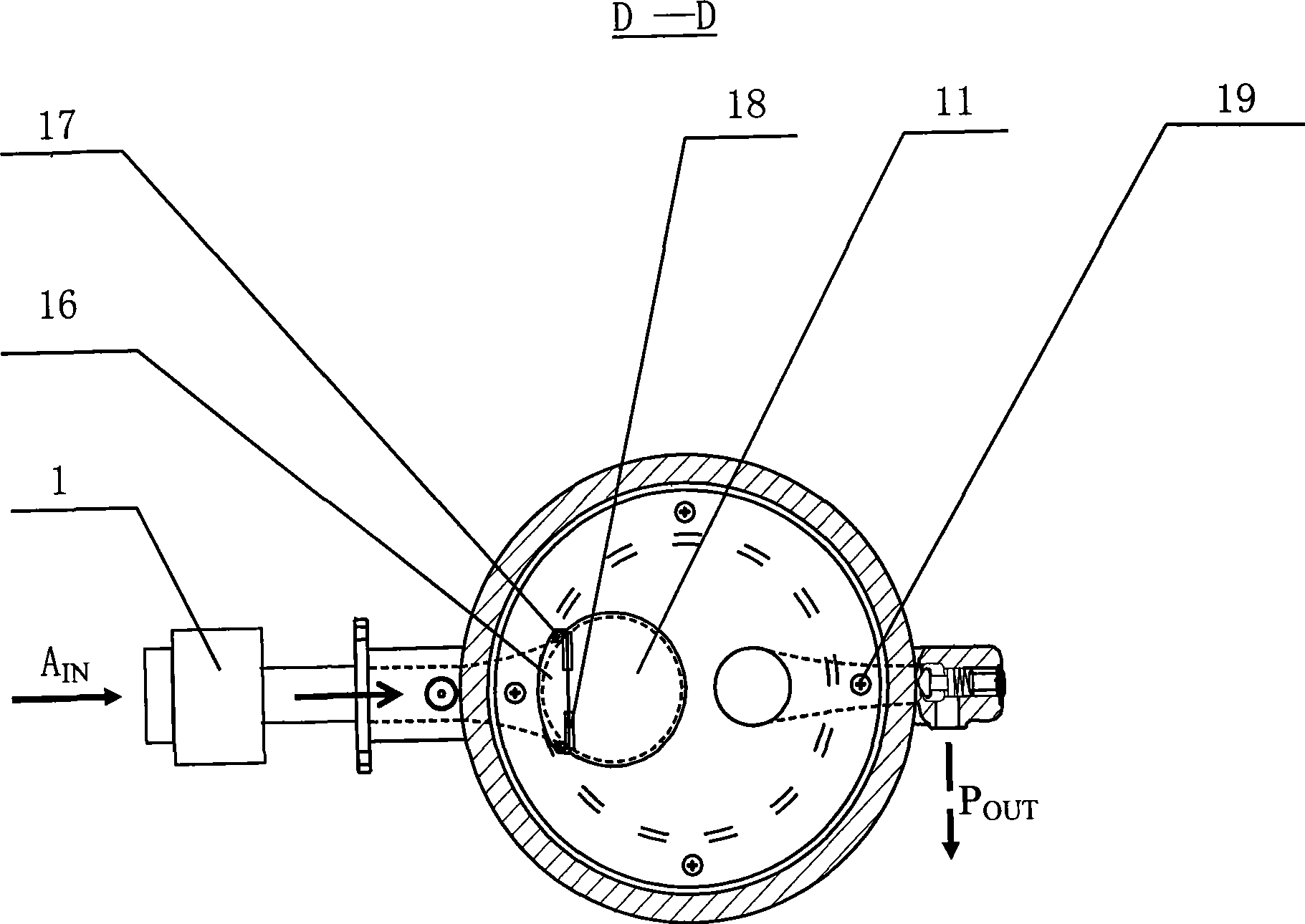

[0013] The structure of an embodiment of the automatic backwashing device (referred to as the device) of the present invention (see Figures 1-3), the device includes a water inlet A IN , Outlet C OUT and outfall P OUT cylinder 3, the cylinder 3 is equipped with a filter screen, which is characterized in that the device is a vertical design, the water inlet A IN It is opened at the lower part of the cylinder wall, and is equipped with a water inlet (one-way) valve 1; the water outlet C OUT It is opened on the upper part of the cylinder wall, and a water outlet (one-way) valve 12 is installed; the sewage outlet P OUT Open at the lower part of the cylinder wall and the water inlet A IN The corresponding other side is equipped with a (one-way) blowdown valve; the cylinder body 3 is sealed and fitted (through the sealing gasket 4 and the bol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com