Overturning plate type bio-membrane reactor

A technology of biofilm reactor and turning plate, which is applied in the field of water treatment, can solve the problems of incomplete backwashing of biofilm reactor carrier filler, complicated reaction condition control activated sludge method, etc. Good effect, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

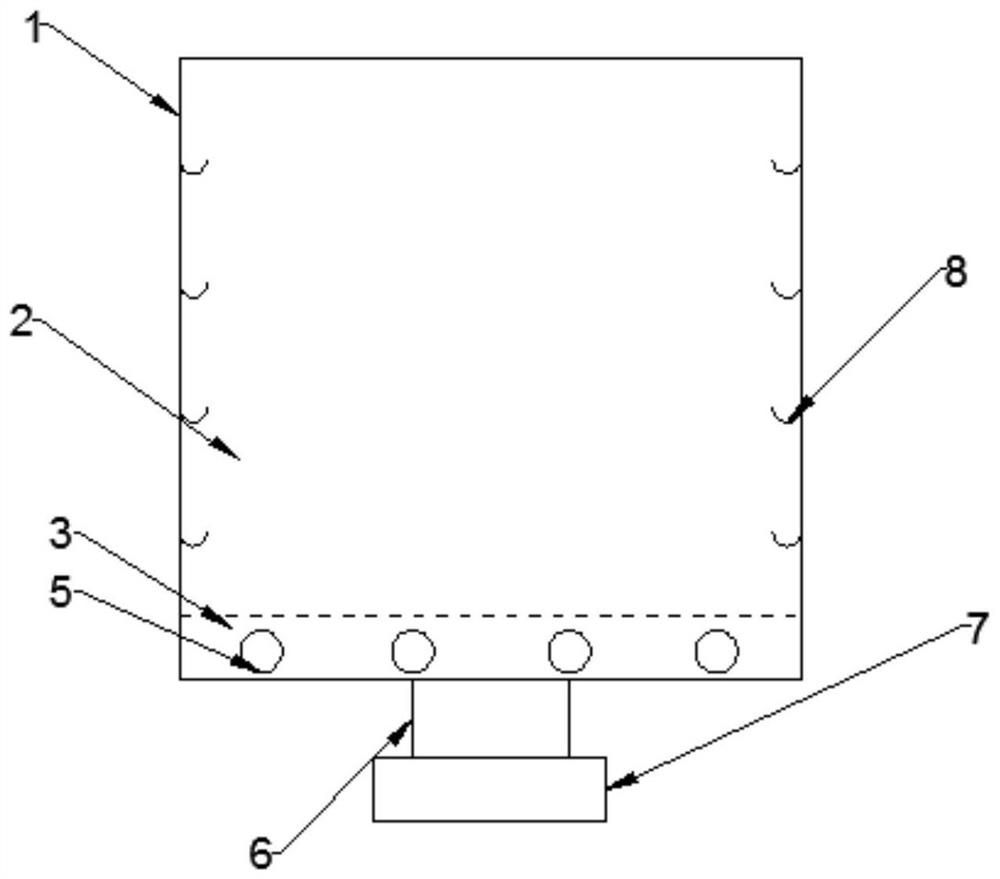

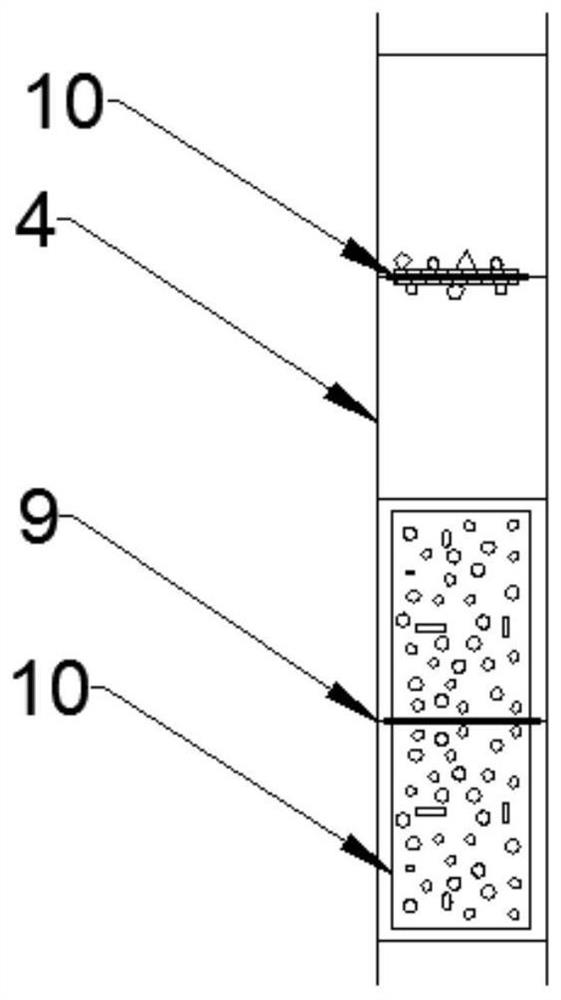

[0028] Such as Figure 1 to Figure 5 As shown, an inverted plate biofilm reactor includes a reactor shell 1, an inverted plate carrier area 2 and an aeration area 3, and the inverted plate carrier area 2 is on the upper part of the aeration area 3. The flip plate carrier area 2 includes multiple sets of flip plate carrier assemblies; the aeration area 3 is provided with microporous aeration heads 5 . A sludge outlet 6 and a valve 7 are provided at the middle of the bottom of the aeration zone 3 to control the discharge of sludge.

[0029] The reactor shell 1 is cylindrical, preferably made of stainless steel; the inner wall of the reactor shell 1 is evenly provided with a plurality of crotches 8 for fixing the flip plate carrier assembly, preferably, the number of the crotch 8 is 2 times the number of board carrier components.

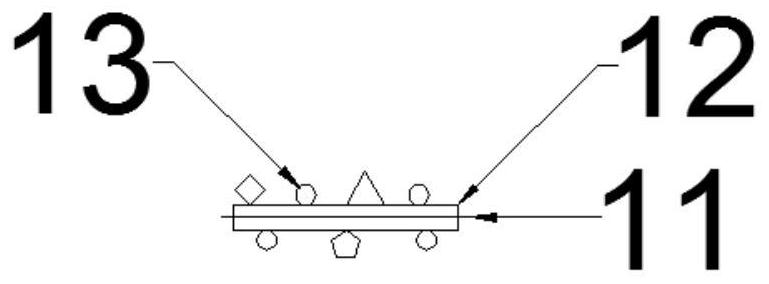

[0030] The flip plate carrier assembly includes a carrier skeleton 4 and a square rotating carrier 10 . Wherein, the carrier frame 4 is formed by a...

Embodiment 2

[0035] An inverted plate biofilm reactor comprises a reactor shell 1, an inverted plate carrier area 2 and an aeration area 3, and the inverted plate carrier area 2 is at the upper part of the aeration area 3. The flip plate carrier area 2 includes multiple sets of flip plate carrier assemblies; the aeration area 3 is provided with microporous aeration heads 5 . A sludge outlet 6 and a valve 7 are provided at the middle of the bottom of the aeration zone 3 to control the discharge of sludge.

[0036] The reactor shell 1 is a cube, preferably, the material is plexiglass; the inner wall of the reactor shell 1 is uniformly provided with a plurality of crotches 8 for fixing the flip plate carrier assembly, preferably, the number of the crotch 8 is 2 4 times the number of board carrier components.

[0037]The flip plate carrier assembly includes a carrier skeleton 4 and a square rotating carrier 10 . Wherein the carrier skeleton 4 is made of a rectangular structure connected by b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com