Surface treatment wastewater recycling device

A technology for wastewater recovery and surface treatment, applied in filtration treatment, special treatment targets, multi-stage water treatment, etc. Disassembly and cleaning, easy to clean and replace, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

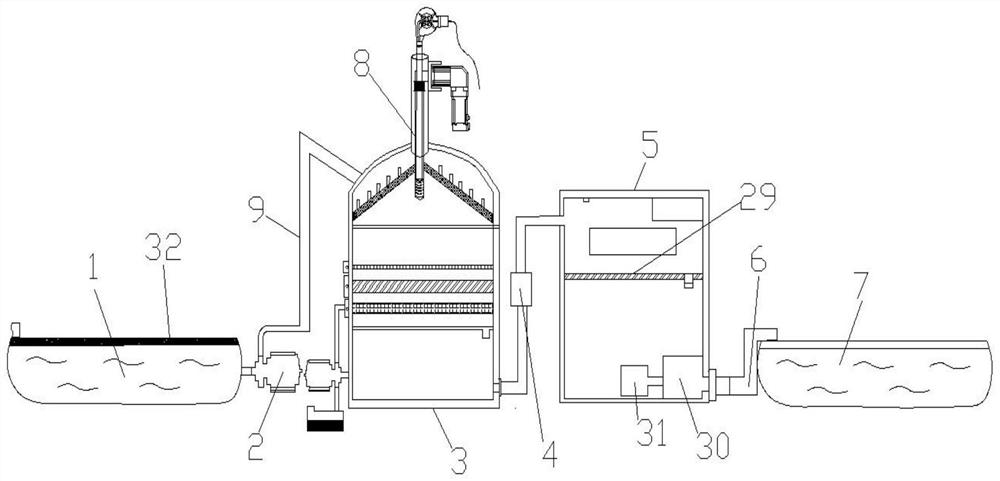

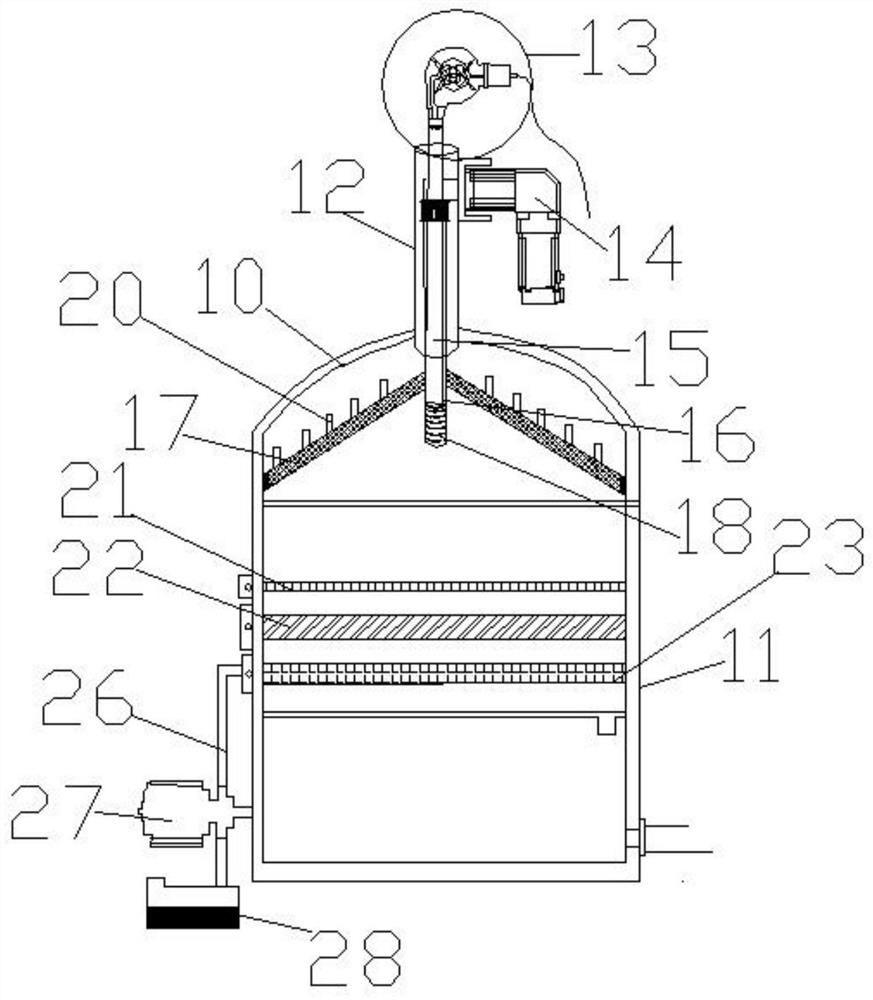

[0031] Example: see Figure 1-7 as shown,

[0032] A surface treatment wastewater recycling device, comprising a collection pool 1, the right side of the collection pool 1 is fixedly connected to a lifting pump 2, the upper end of the lifting pump 2 is fixedly connected to a first water pipe 9, and the first water pipe 9 is fixedly connected to a first filter device 3, the first The right side of the filter device 3 is fixedly connected to the RO water supply pump 4, and the first filter device 3 is provided with a rotary air jet device 8, the right side of the RO water supply pump 4 is fixedly connected to the second filter device 5, and the right side of the second filter device 5 is fixedly connected to a The second water pipe 6, the second water pipe 6 is fixedly connected to the recycling pool 7;

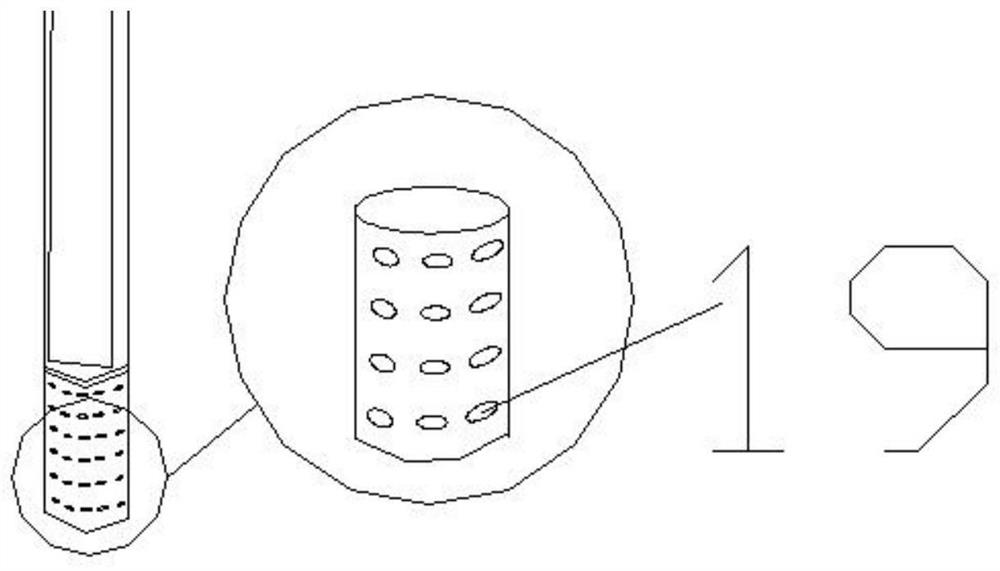

[0033]The first filtering device 3 includes a circular cover 10 and a rectangular body 11, the circular cover 10 and the rectangular body 11 are combined to form a sealed cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com