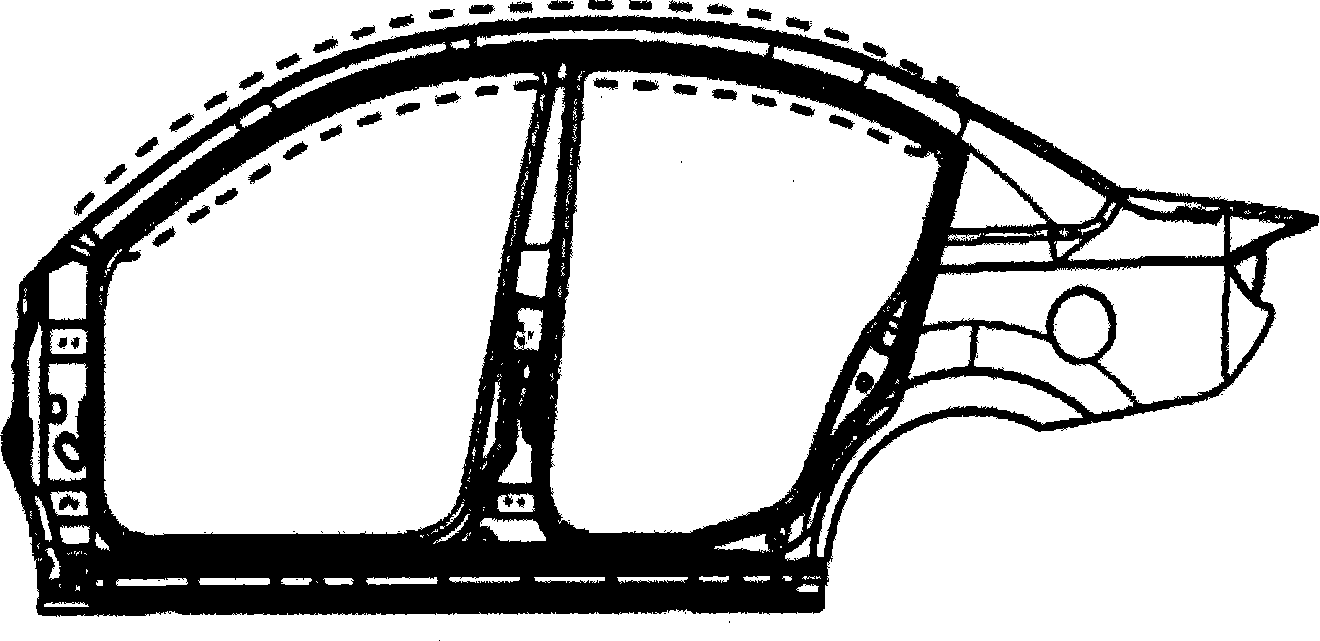

Stamping processing method for related joint of vehicle side-frame outer plate and roof board

A processing method and technology for side wall outer panels, which are applied in the fields of stamping manufacturing and sheet metal forming analysis of automotive body-in-white sheet metal parts, which can solve problems such as large inflow of materials, wrinkled and stacked materials, and wear of concave mold fillets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The theoretical research of the present invention is discussed below.

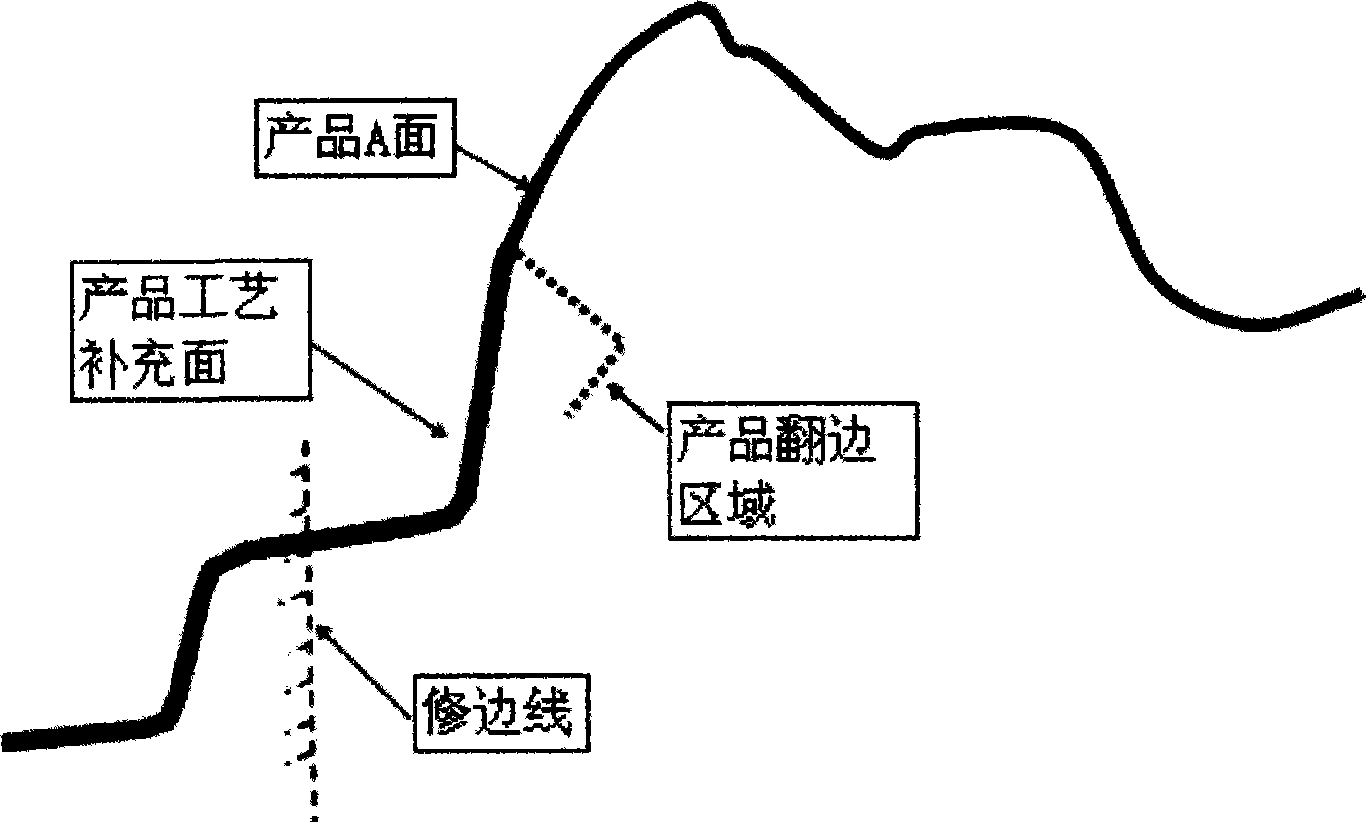

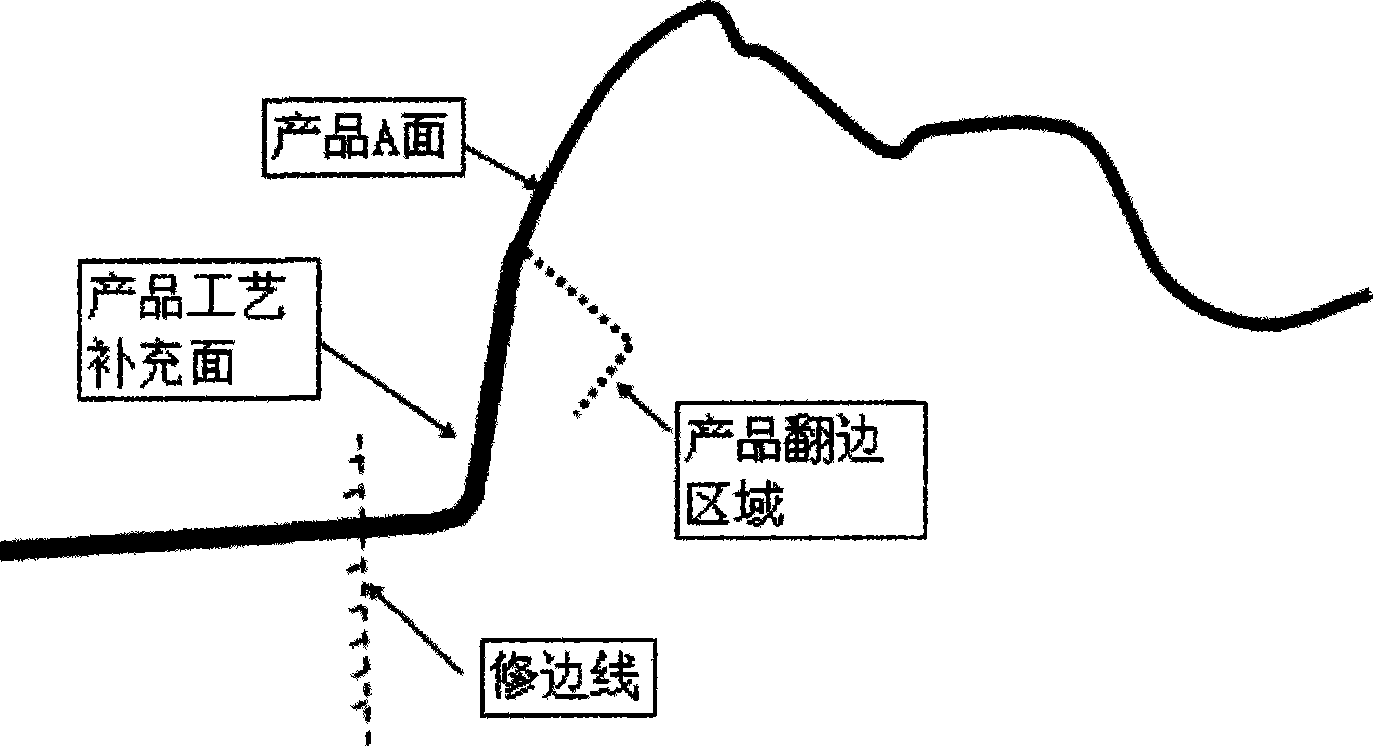

[0025] 1. Research on sheet metal compression before and after side shaping of corresponding parts (combined with Figure 5 )

[0026] The sheet material is stretched and compressed under the action of the mold, and the extension state of the part with the same circle center and different radii before and after side shaping (such as Figure 5 Middle A, B): L1 represents the state of the product side after shaping, the length is 100mm; L2 represents the length of the sheet when it is stretched to the first radius state, and the length is 105mm; L3 represents the state when the sheet is stretched to the second radius, The length is 110mm. When comparing the flanging of the sheet metal from the L2 and L3 states to the L1 position, the compression amount of the two (this compression amount is the main cause of deformation and wrinkling) is as follows:

[0027] A%=(105-100) / 100=5%

[0028] B%=(110-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com