Heating layer and heating method of megawatt level wind-powered blade mold

A technology for wind turbine blades and heating layers, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as unsafe electric heating, equipment production impact, etc., to reduce production costs, ensure molding quality, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

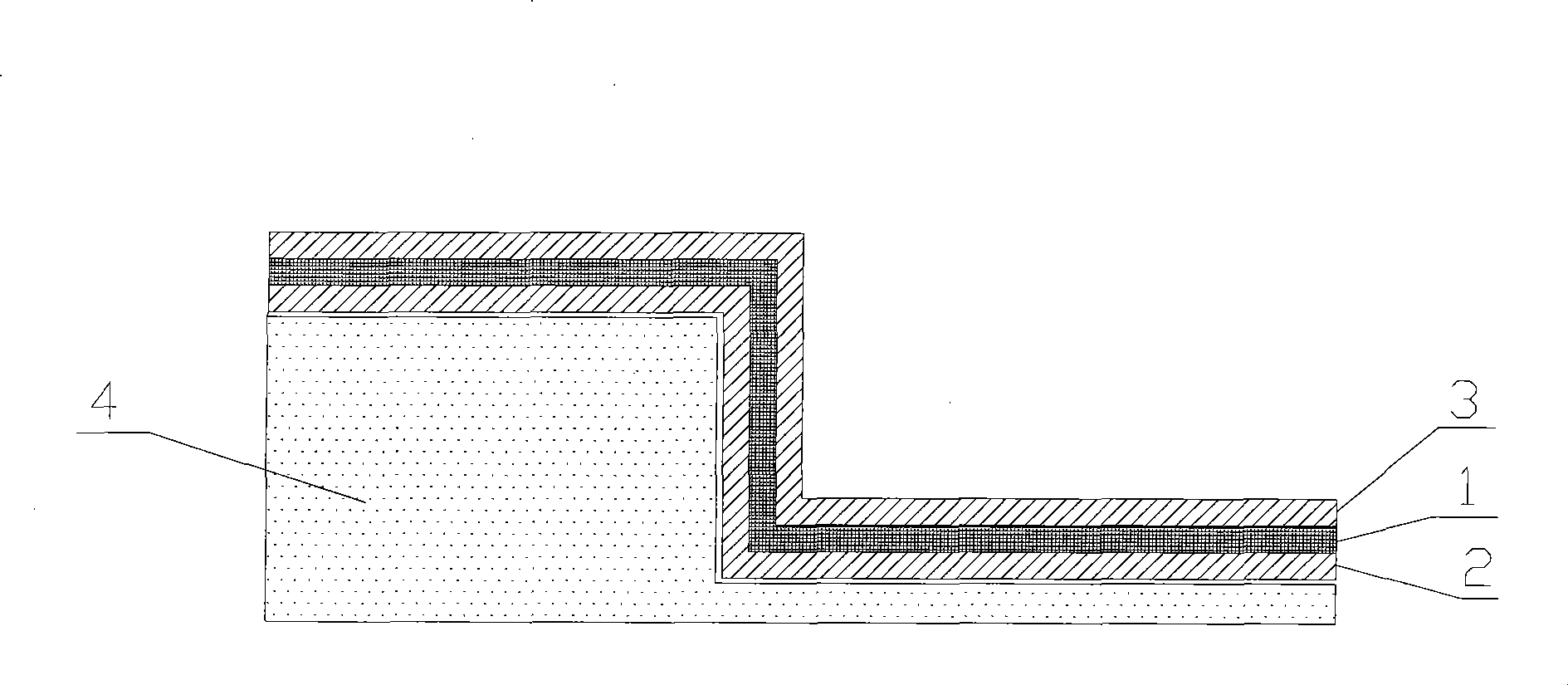

[0023] The invention provides a heating layer of a megawatt-level wind power blade mold and a heating method for the heating layer. The heating layer is arranged between the inner structure layer and the outer structure layer arranged on the outer layer of the mother mold, wherein the inner structure layer The molding of the inner and outer structural layers adopts the existing technology: the inner and outer structural layers are resin-based composite material layers, which are formed by a vacuum-assisted infusion process, and mainly play a role in maintaining the rigidity of the mold cavity.

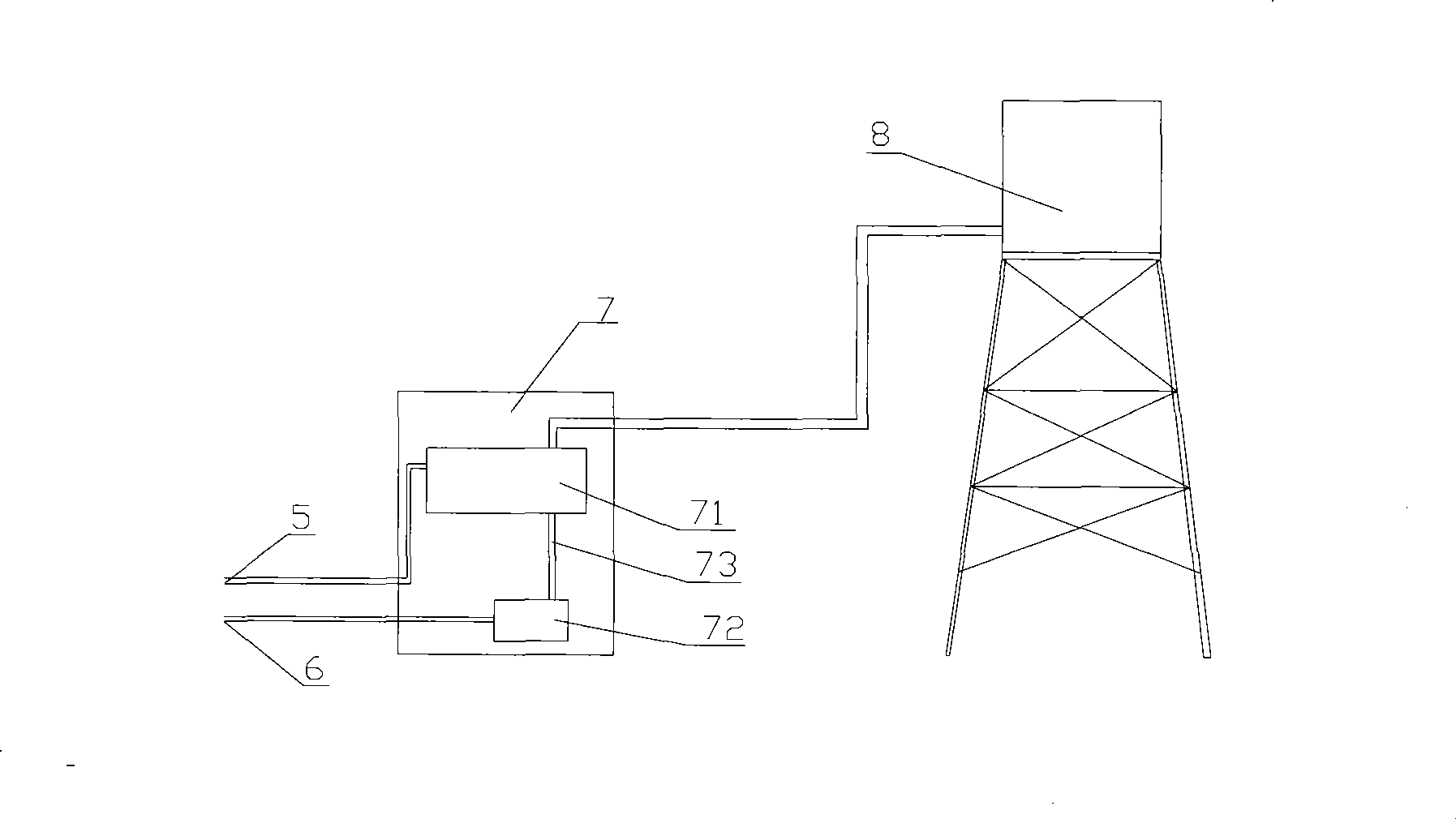

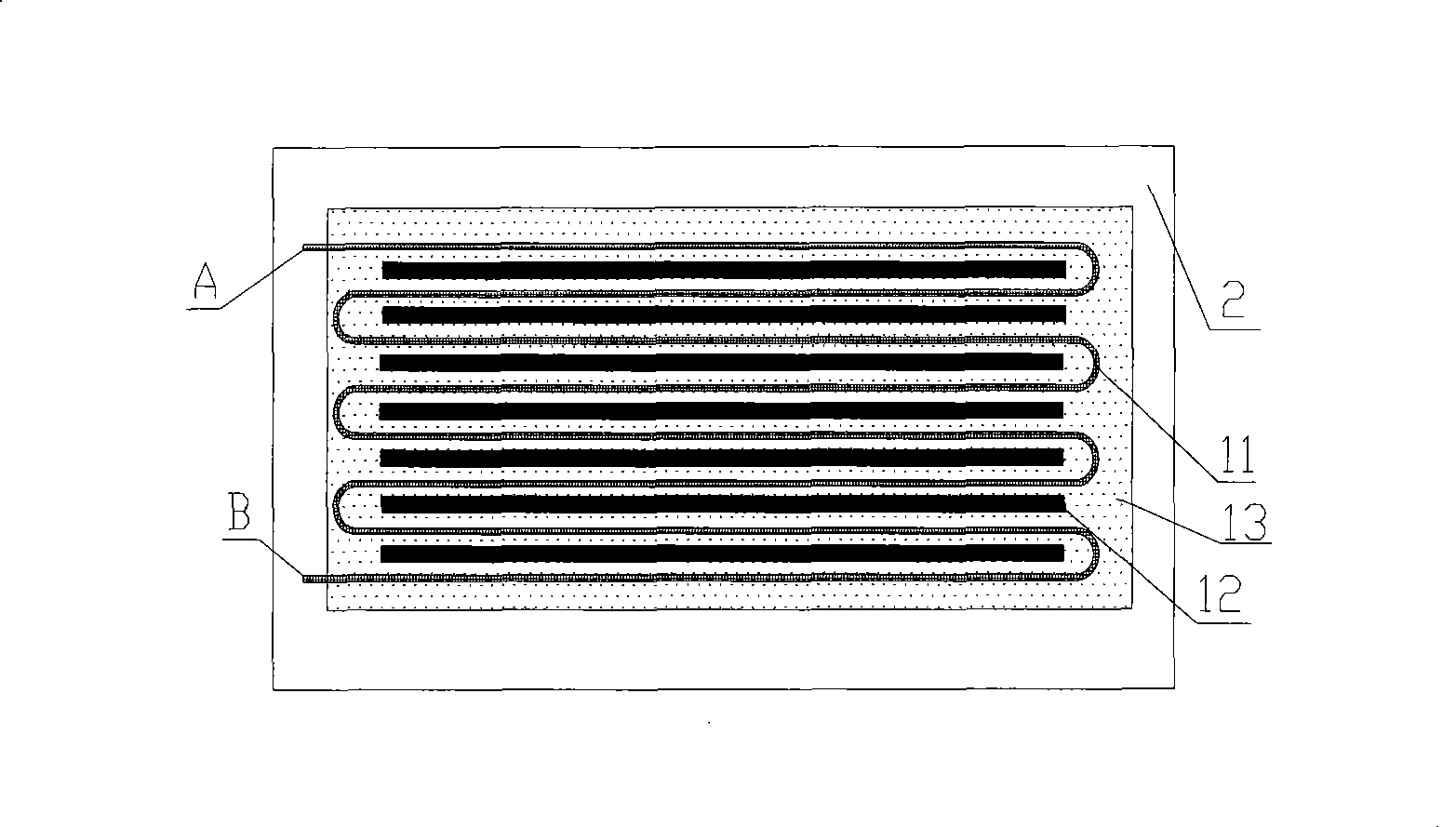

[0024] According to the shape and thickness of the blade, the surface of the master mold at the blade root, leaf center and blade tip is covered with several water circulation channels bent by diversion copper tubes with good thermal conductivity. The two ports protrude from the surface of the outer structural layer, and are respectively connected to the water inlet and outlet pipes set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com