Mould for glass lens moulding and glass lens moulding method

A glass lens and forming mold technology, applied in glass forming, glass production, glass pressing and other directions, can solve the problems of slow production speed, heating and heating, long cooling and cooling time, etc., to improve production efficiency and improve the pass rate , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings and embodiments.

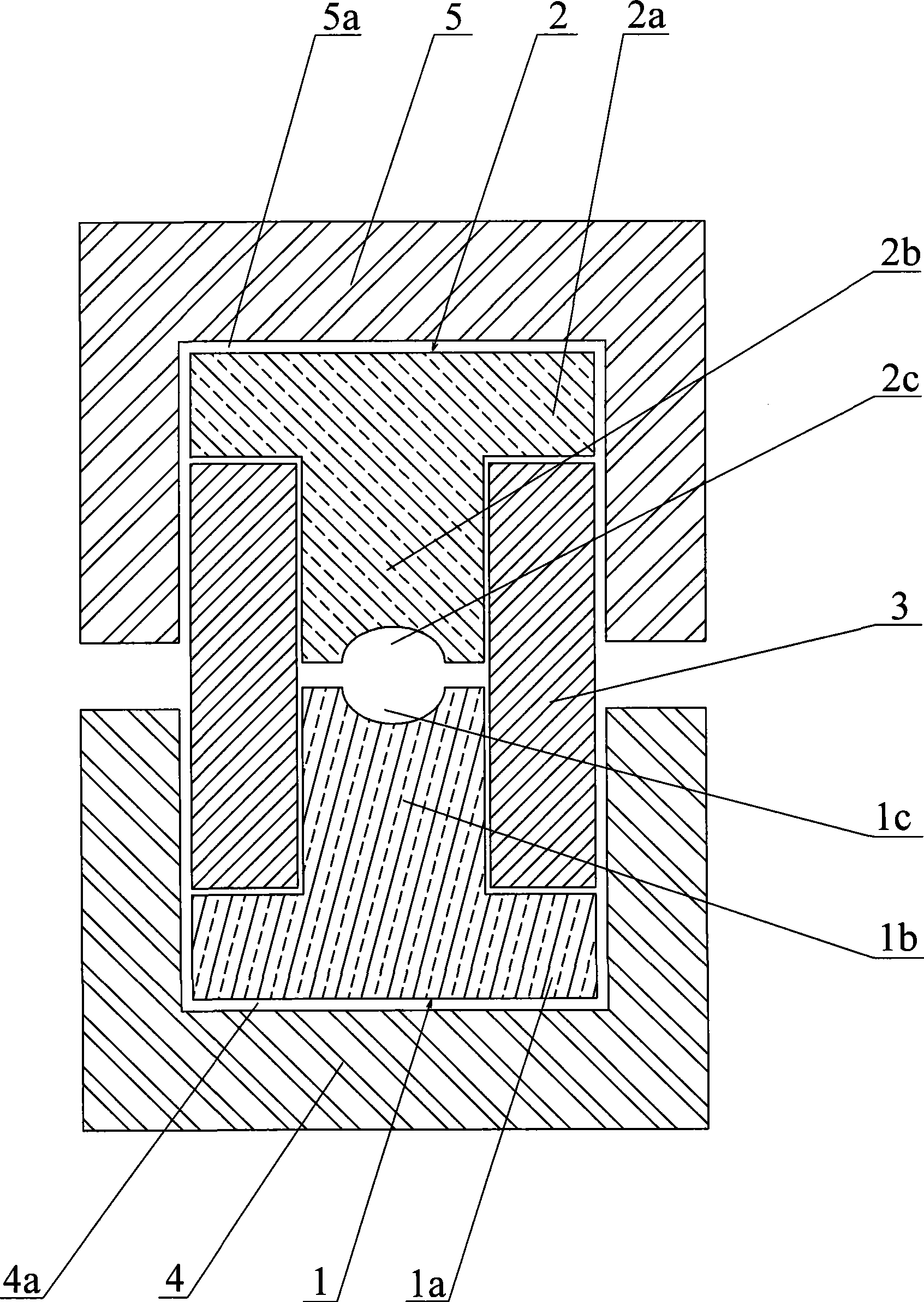

[0030] As shown in the figure: the present invention mainly consists of a lower mold core 1, a bottom plate 1a, a lower cylinder 1b, a lower mold cavity 1c, an upper mold core 2, a top plate 2a, an upper cylinder 2b, an upper mold cavity 2c, a tubular mold cover 3, The base 4, the lower installation depression 4a, the gravity mound 5 and the upper installation depression 5a are formed.

[0031] The glass lens molding mold of the present invention comprises a lower mold core 1 formed by a bottom plate 1a and a lower cylinder 1b integrally connected upwardly protruding from the upper surface of the bottom plate 1a, the cross section of the lower mold core 1 is convex, and the lower cylinder 1b The depression provided on the upper end surface of the upper end surface forms the lower mold cavity 1c, and the upper mold core 2 is arranged above the lower mold core 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com