Method for producing fly ash haydite

A technology of fly ash ceramsite and fly ash, which is applied in the field of building materials manufacturing, can solve the problems of poor product quality stability, low output, large formula differences, etc., and achieve easy quality assurance, reduced production costs, and close color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

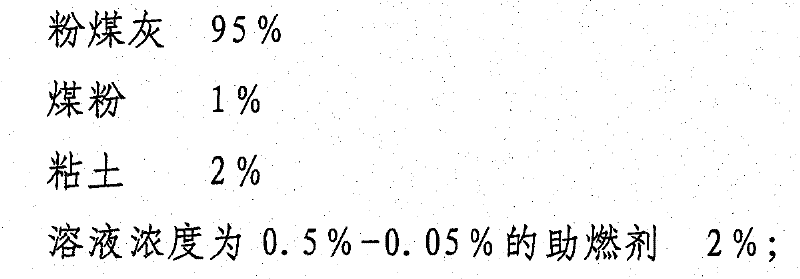

[0018] The material for producing fly ash ceramsite in the present invention includes fly ash, coal powder, clay and a combustion-supporting agent, wherein the combustion-supporting agent is a commercially available chemical solvent product including a coal-burning combustion-supporting agent, a boiler combustion-supporting agent or a diesel combustion-supporting agent, The weight ratio is as follows:

[0019] Fly ash 95%;

[0020] Coal powder 1%;

[0021] Clay 2%;

[0022] Combustion enhancer 2% (the concentration of the prepared solution is 0.5%-0.05%).

[0023] The process flow is as follows:

[0024] 1. Put the fly ash, coal powder and clay into the mixer in proportion to fully stir and mix evenly to form a mixture;

[0025] 2. Dilute the combustion aid with water to a solution with a concentration of 0.5%-0.05%;

[0026] 3. Put the mixture into the ball forming disc of the disc granulator, and spray the combustion aid solution upwards, and roll to make fly ash cerams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com