Method for decomposing ore concentrate containing tantalum, niobium and rare-earth element

A rare earth element and concentrate technology is applied in the field of decomposition of rare earth element concentrates containing tantalum and niobium, and can solve problems such as complex processes

Inactive Publication Date: 2010-09-08

GUANGZHOU RES INST OF NON FERROUS METALS +1

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method also needs to decompose tantalum, niobium and rare earth elements separately, and the process is complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a method for decomposing a concentrated ore containing tantalum, niobium and rare-earth elements, which is characterized by comprising the following steps: evenly mixing the concentrated ore containing the tantalum, niobium and rare-earth elements, concentrated sulfuric acid and sulfate according to a weight ratio of 1:0.8-2.5:0.8:1.5, roasting the mixture for 0.5 to 8 hours at a temperature of between 180 and 400 DEG C; adding water into the mixture after roasting, stirring the mixture for 0.5 to 3 hours at a temperature of between 20 and 80 DEG C; and filtering and washing the mixture, wherein the tantalum, the niobium and the rare-earth elements enter the solution. The method decomposes the tantalum, the niobium and the rare-earth elements, and improves leaching rate of the tantalum and the niobium at the same time, wherein the leaching rate of the rare-earth elements reaches more than 90 percent, and the method prepares for next separation.

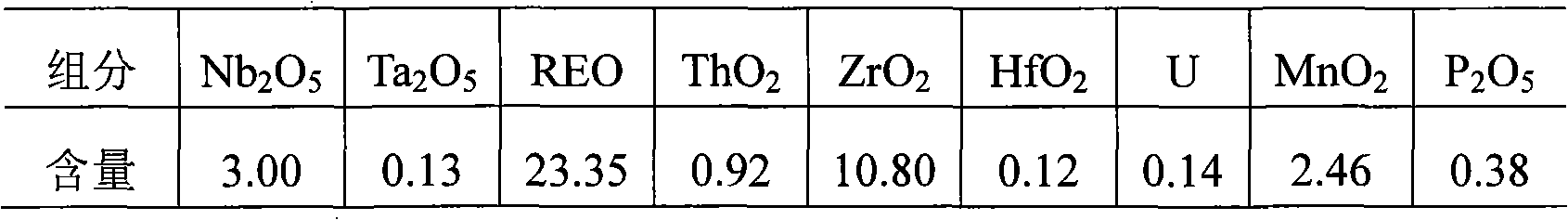

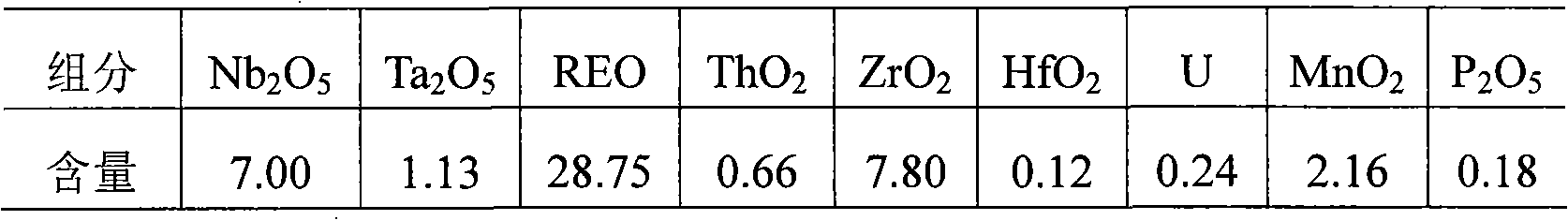

Description

technical field The invention relates to a method for decomposing rare earth element concentrates, in particular to a method for decomposing rare earth element concentrates containing tantalum and niobium. Background technique With the increasing consumption of rare earth element resources, complex associated rare earth element resources need to be comprehensively developed and utilized. Many associated rare earth element resources contain rare metals such as tantalum and niobium. The elemental concentrate also contains a small amount of tantalum and niobium, about 0.5-40%. "Niobium and Tantalum" (A.B.EЛЮTИH et al., Central South University of Technology Press, P52~P66,) summarizes the current domestic and foreign research on the treatment of rare earth element concentrates containing tantalum and niobium mainly adopts the following methods: 1. Hydrofluoric acid decomposition method . The tantalum and niobium are extracted by hydrofluoric acid leaching, and the rare earth...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22B1/06

Inventor 刘志强陈怀杰梁振锋冯雅清

Owner GUANGZHOU RES INST OF NON FERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com