Digital weighing sensor capable of redounding and self-compensating deflection influence and method thereof

A load cell, digital technology, applied in the field of load cells, can solve the problems of inability to calibrate the load cell, adjust the headache, unable to guarantee the load cell, etc., to simplify the adjustment and correction work and maintenance work, and prevent errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the preferred implementation advantages are specially cited below, together with the accompanying drawings, and the detailed description is as follows:

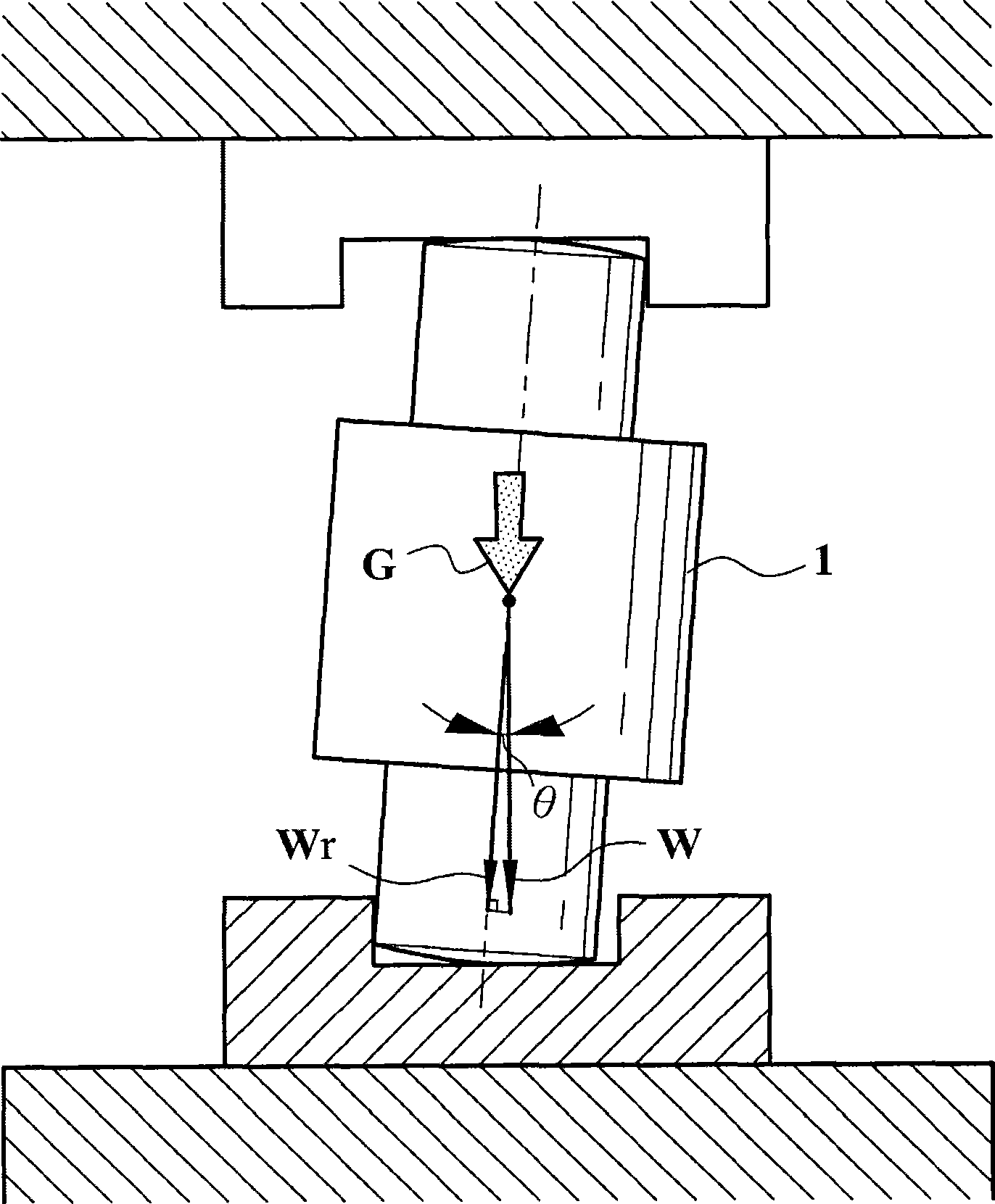

[0046] Such as figure 1 What is shown is a schematic diagram of a load cell 1 in a deflected state. Since there is an included angle θ between the axis and the gravitational direction G, the sensed value Wr is smaller than the actual weighed weight.

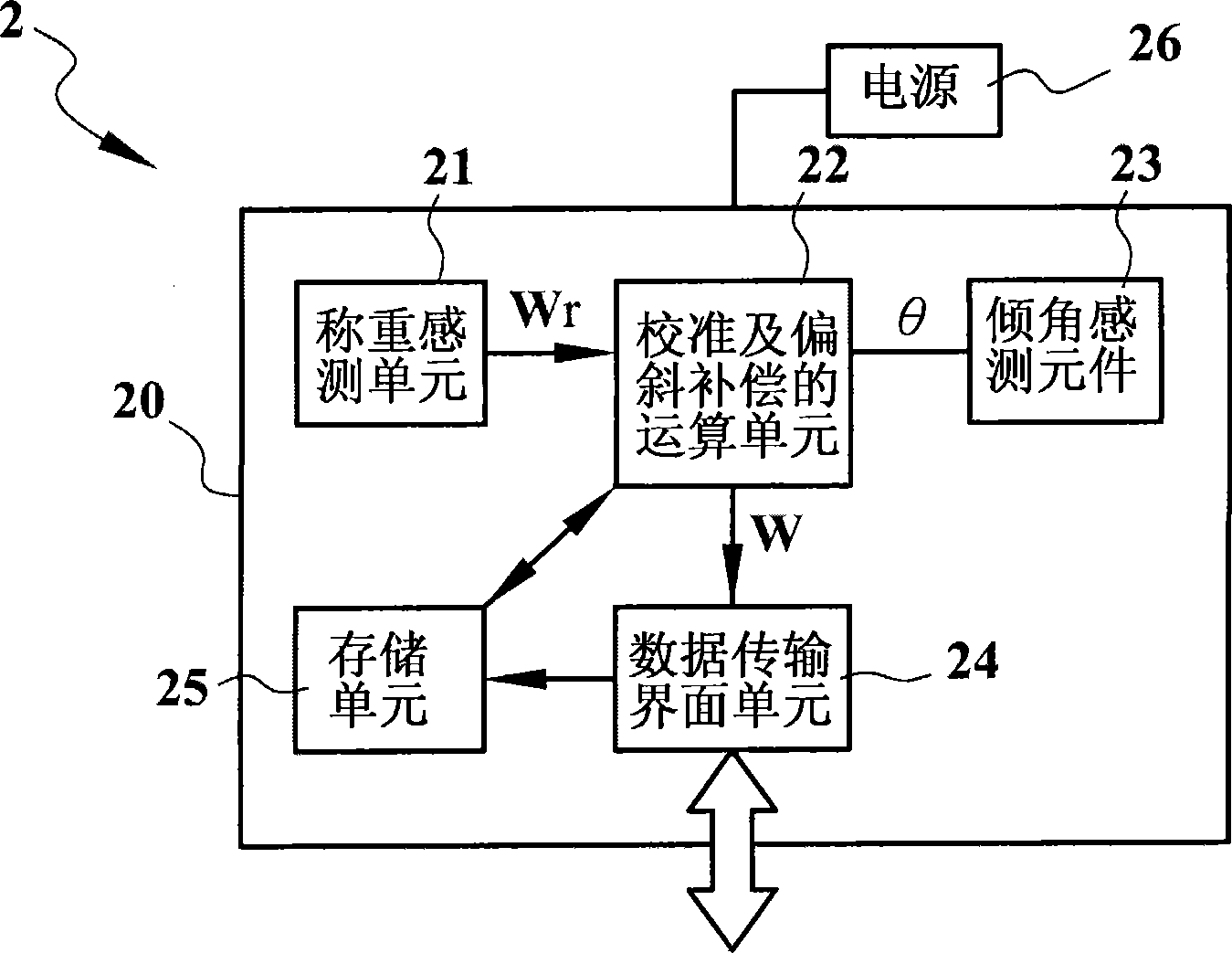

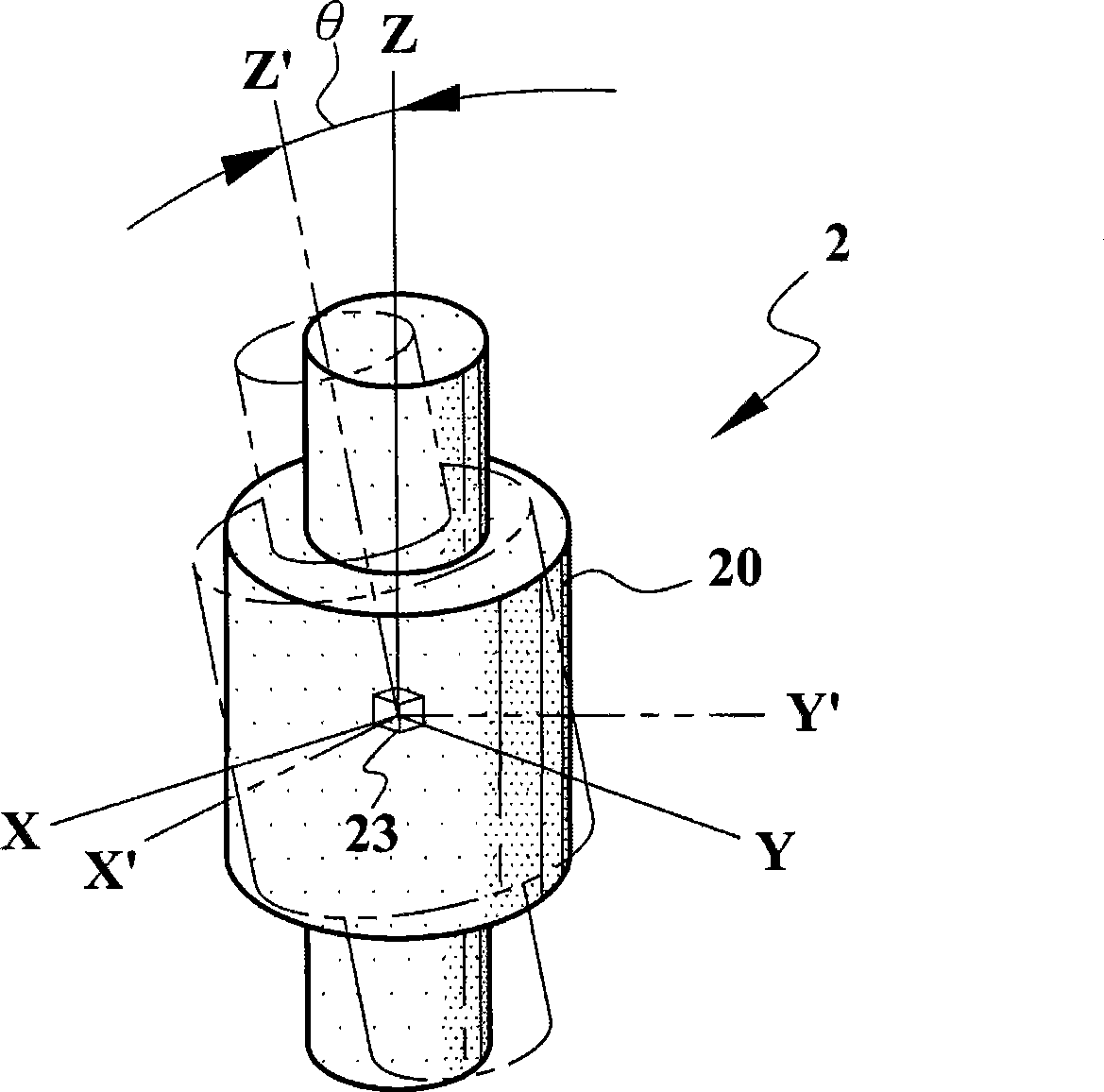

[0047] Such as figure 2 As shown, it is a digital load cell 2 of the present invention, including at least one load sensing unit 21, a calibration and deflection compensation calculation unit 22, and an inclination angle sensing element 23 installed in a casing 20. 1. A data transmission interface unit 24, a storage unit 25 and a power supply 26 are electrically connected to each other to measure the weight of an object and output a W dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com