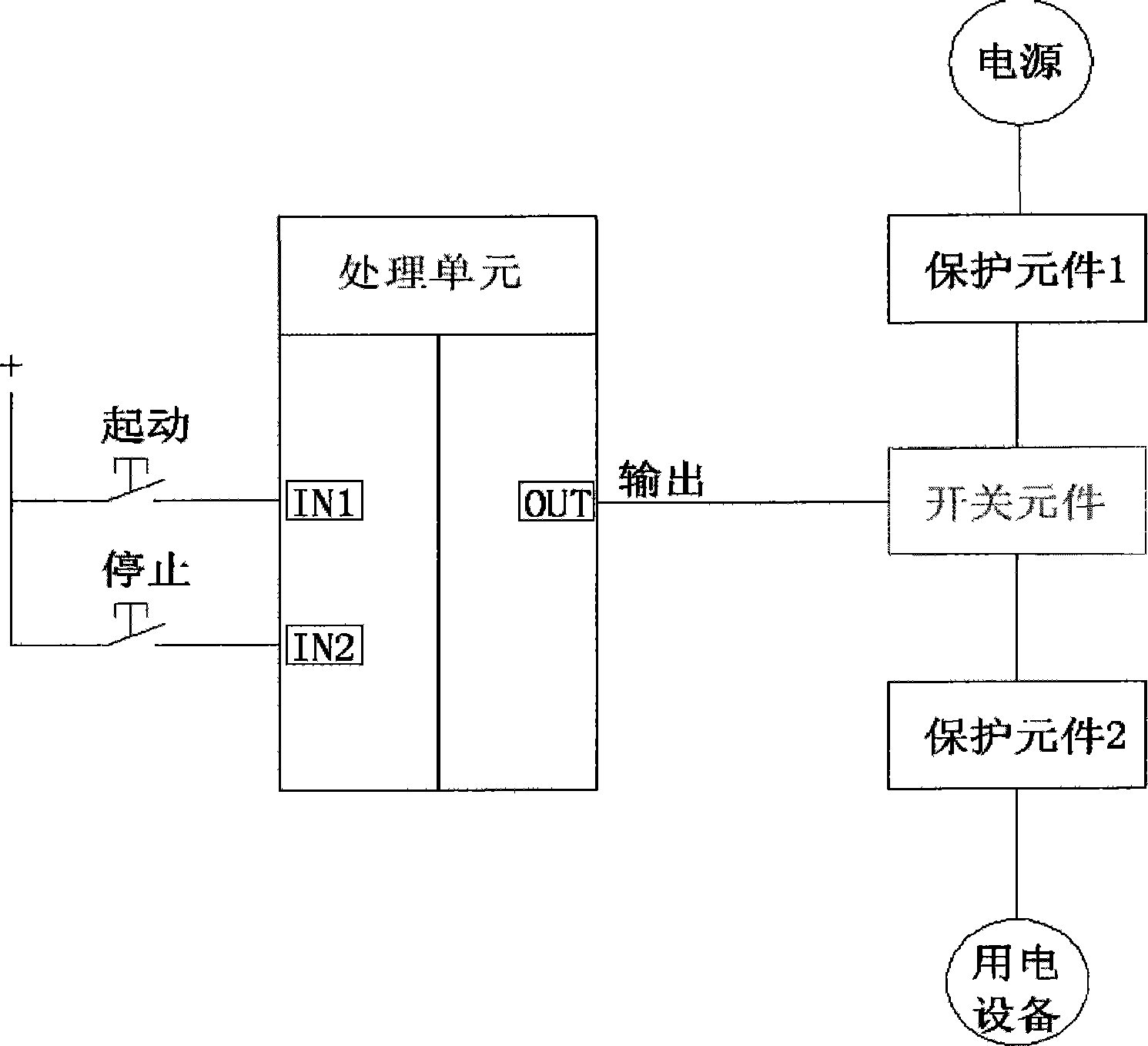

Circuit for controlling device switch and control method thereof

A technology for controlling equipment and controlling switches, which is applied in the direction of program control and electrical program control in sequence/logic controllers, which can solve problems such as large hardware investment, increased cost, and complicated wiring, and achieve hardware cost and installation cost savings. , the effect of reducing the amount of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

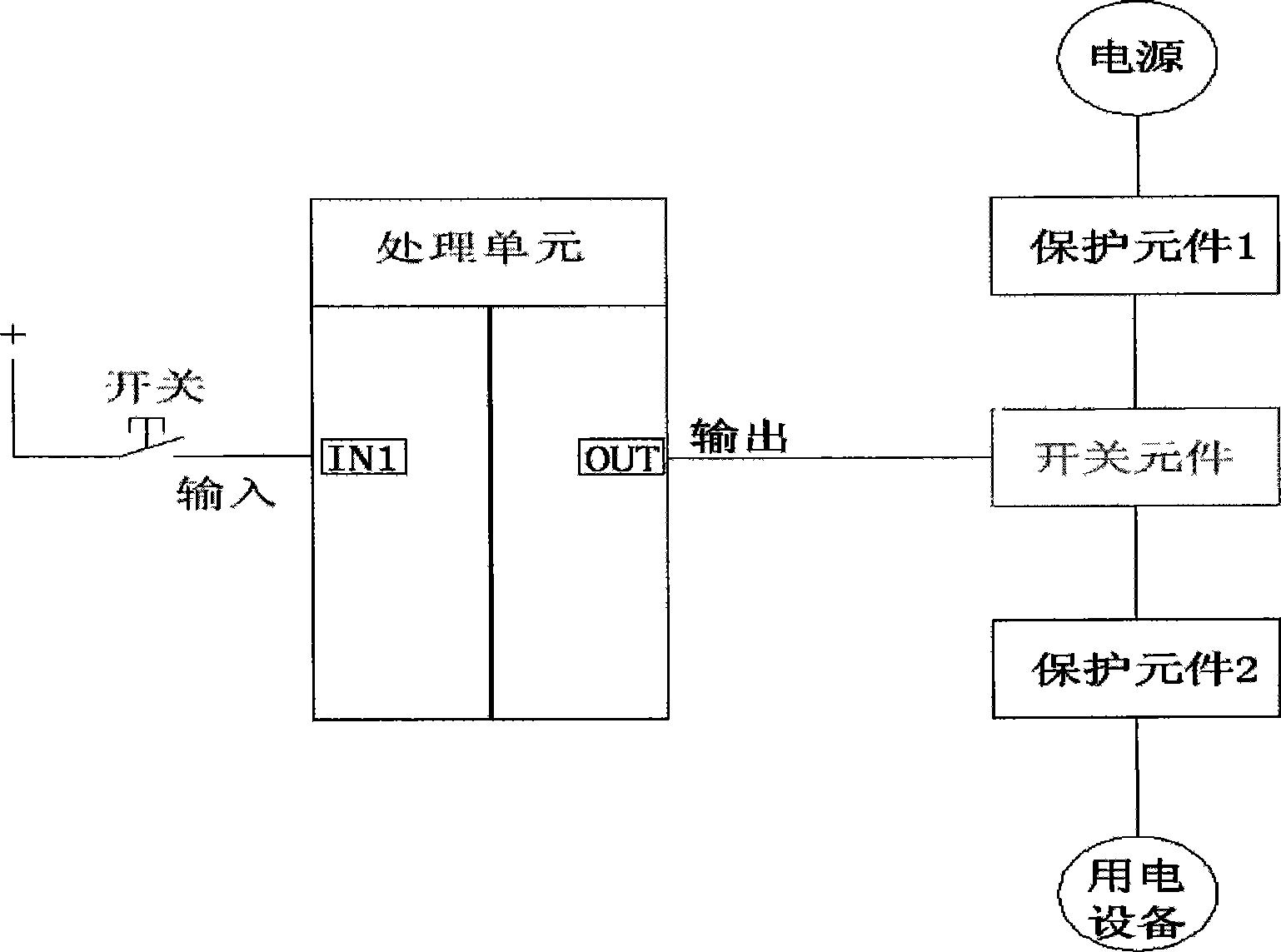

[0018] like figure 2 As shown, in the circuit for controlling the switch of the equipment in this embodiment, a set of equipment corresponds to only one control switch, the control switch is connected to the input terminal of the processing unit, and the signal of the control switch is processed by the processing unit and then output to the output terminal through the output terminal. The switch element of the corresponding electrical equipment controls the switch of the equipment. The processing unit is a PLC.

[0019] The control method of the above circuit is as follows: the processing unit receives the signal of the control switch, and when the processing unit detects the pulse signal of the control switch, the processing unit sends a control signal to change the switch state of the device. The control method can be realized by PLC programming. When the level of the input pin of the PLC changes, the PLC converts the level change into a pulse signal for processing.

Embodiment 2

[0021] Different from the above-mentioned Embodiment 1, the control method of this embodiment is as follows: the processing unit receives the signal of the control switch, when the processing unit detects the pulse signal of the control switch, the control unit changes the data value of its memory, and according to The changed data value of the memory outputs a control signal to change the switch state of the device.

[0022] For example: after the PLC is initialized, the data value of its memory is "0", and the switch state of the corresponding device is "off". When the PLC detects the pulse signal of the control switch, the PLC first changes the data value of its memory to "1" ”, and then send a control signal to turn on the device, so that the data value of the PLC memory corresponds to the switch state of the controlled device, that is, the data value of the memory “0” corresponds to the “off” state of the device, and “1” corresponds to the “off” state of the device. The "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com