Lotion light type eyeshadow cream

An eye shadow cream, refreshing technology, applied in the directions of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems such as easy shiny eyes, sticky users, and difficult long-lasting makeup, so as to achieve natural long-lasting and increased eye makeup Desire, the effect of increasing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

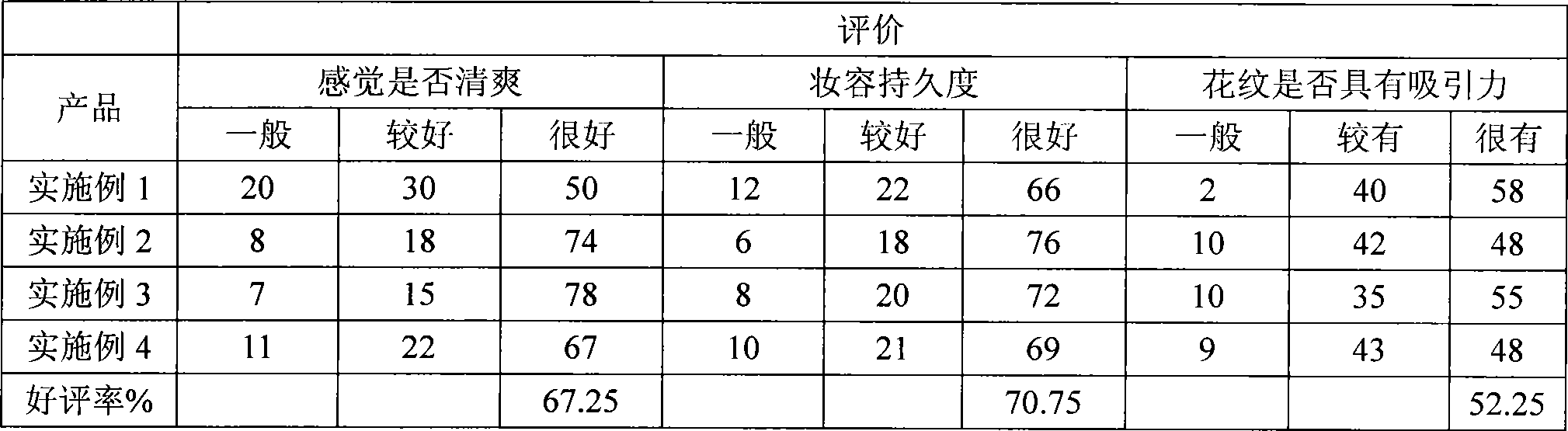

Examples

Embodiment 1

[0034] 1. Weigh the components in proportion:

[0035] Component A: 100g of ethylhexyl palmitate, 100g of siloxane, 50g of silica dimethyl silylate;

[0036] Component B: 100g beeswax, 100g ozokerite wax, 50g silicone wax, 20g phenoxyethanol, 50g lecithin;

[0037] Component C: talc powder 100g, pearl powder 100g;

[0038] 2. Mix and heat component A to 70°C, mix and heat component B to 90°C; add component B to component A while stirring, and add component C after mixing well; combine components A and B and the mixture of C is cooled to room temperature;

[0039] 3. Heat the mixture prepared in step 2 to 80°C, fill it in a corresponding container, sprinkle a layer of pearl powder on the surface after cooling, and press the pattern with a mold with a pattern.

Embodiment 2

[0041] 1. Weigh the components in proportion:

[0042] Component A: 50g of ethylhexyl palmitate, 50g of siloxane, 1.5g of silica dimethyl silylate;

[0043] Component B: 10g beeswax, 10g ozokerite wax, 2.0g silicone wax, 0.5g phenoxyethanol, 2g polyol polylinoleate;

[0044] Component C: talcum powder 40g, pearl powder 40g;

[0045] D component: essence 0.5g.

[0046] 2. Mix and heat component A to 80°C, mix and heat component B to 100°C; add component B to component A while stirring, and add component C after mixing well; combine components A and B Cool the mixture with C to 60°C, add component D, stir well, and cool to room temperature;

[0047] 3. Heat the mixture prepared in step 2 to 90°C, fill it in a corresponding container, sprinkle a layer of pearl powder on the surface after cooling, and press the pattern with a mold with a pattern.

Embodiment 3

[0049] 1. Weigh each component in proportion:

[0050] Component A: 10g of ethylhexyl palmitate, 10g of siloxane, 0.5g of silica dimethyl silylate;

[0051] Component B: 8g beeswax, 8g ozokerite, 2g silicone wax, 0.4g phenoxyethanol, 1.5g isopropyl myristate;

[0052] Component C: talcum powder 40g, pearl powder 40g;

[0053] D component: essence 0.3g.

[0054] 2. Mix and stir component A and heat to 80°C, mix and heat component B to 95°C; add component B to component A while stirring, add component C after mixing evenly; combine components A and B Cool the mixture with C to 55°C, add component D, stir well, and cool to room temperature;

[0055] 3. Heat the mixture prepared in step 2 to 85°C, fill it in a corresponding container, sprinkle a layer of pearl powder on the surface after cooling, and press the pattern with a patterned mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com