Method for preparing multi-temperature refrigerator with variable evaporation temperature

A technology of evaporation temperature and operation method, applied in the field of non-azeotropic mixed working fluid, can solve the problems such as the reduction of the effective energy utilization coefficient and the difficulty in controlling the temperature of the compartment, so as to improve the effective energy utilization coefficient, reduce energy consumption, and optimize heat transfer. The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

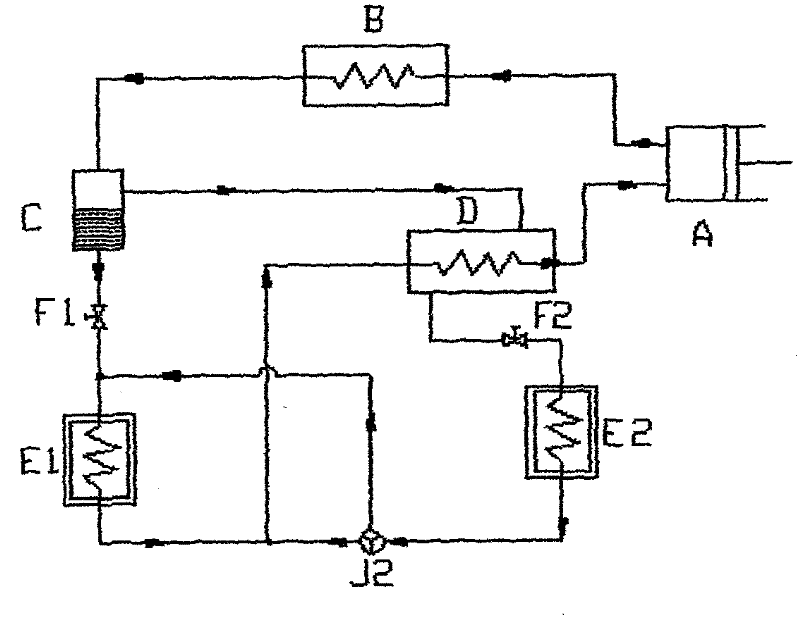

[0020] Embodiment 1: see figure 1 , a multi-temperature refrigerator with two-stage evaporation temperature and the evaporation temperature of the high-temperature evaporator can be adjusted within a certain range, including a refrigeration compressor A, a condenser B, a gas-liquid separator C, a condensation evaporator D, and a first throttle valve F1 and the second throttle valve F2, high temperature evaporator E1, low temperature evaporator E2 and three-way flow distribution valve J2. The device uses a two-element or multi-element non-azeotropic mixed working medium, and its cycle flow is: the high-pressure exhaust port of the refrigeration compressor A is connected to the condenser B, and the mixed refrigerant vapor is partially condensed in the condenser B to become a gas-liquid The two phases enter the gas-liquid separator C, and in the gas-liquid separator C, the gas-phase working medium containing more low-boiling point component refrigerants and the liquid-phase worki...

Embodiment 2

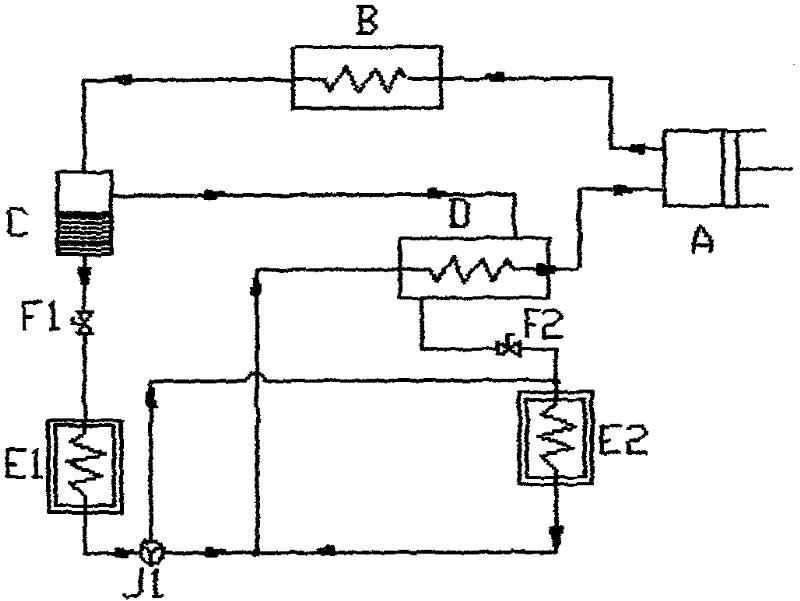

[0024] Example 2: see figure 2, a multi-temperature refrigerator with two-stage evaporating temperature and the evaporating temperature of the low-temperature evaporator can be adjusted within a certain range, including a refrigeration compressor A, a condenser B, a gas-liquid separator C, a condensing evaporator D, and a first throttle valve F1 and the second throttle valve F2, high temperature evaporator E1, low temperature evaporator E2 and three-way flow distribution valve J1. The device uses a two-element or multi-element non-azeotropic mixed working medium, and its cycle flow is: the high-pressure exhaust port of the refrigeration compressor A is connected to the condenser B, and the mixed refrigerant vapor is partially condensed in the condenser B to become a gas-liquid The two phases enter the gas-liquid separator C, and in the gas-liquid separator C, the gas-phase working medium containing more low-boiling point component refrigerants and the liquid-phase working med...

Embodiment 3

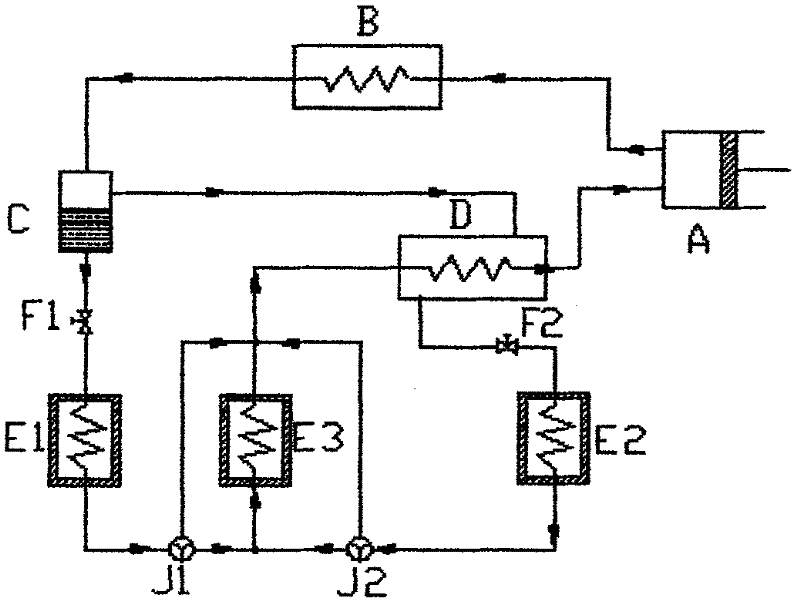

[0029] Embodiment 3: see image 3 , a multi-temperature refrigerator with three-stage evaporating temperature and the evaporating temperature of the first-stage evaporator can be adjusted within a certain range, including refrigeration compressor A, condenser B, gas-liquid separator C, condensation evaporator D, the first section Throttle valve F1 and second throttle valve F2, high temperature evaporator E1, low temperature evaporator E2, variable temperature chamber evaporator E3 and three-way flow distribution valves J1, J2. The device uses a two-element or multi-element non-azeotropic mixed working medium, and its cycle flow is: the high-pressure exhaust port of the refrigeration compressor A is connected to the condenser B, and the mixed refrigerant vapor is partially condensed in the condenser B to become a gas-liquid The two phases enter the gas-liquid separator C, and in the gas-liquid separator C, the gas-phase working medium containing more low-boiling point component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com