a co 2 Solar power generation method and power generation system as working medium

A technology of solar energy and tower solar energy, applied in solar thermal power generation, mechanical power generated by solar energy, machine/engine, etc., can solve problems such as low expansion ratio and low thermal efficiency, achieve heat reduction, improve conversion efficiency, and reduce heat transfer The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

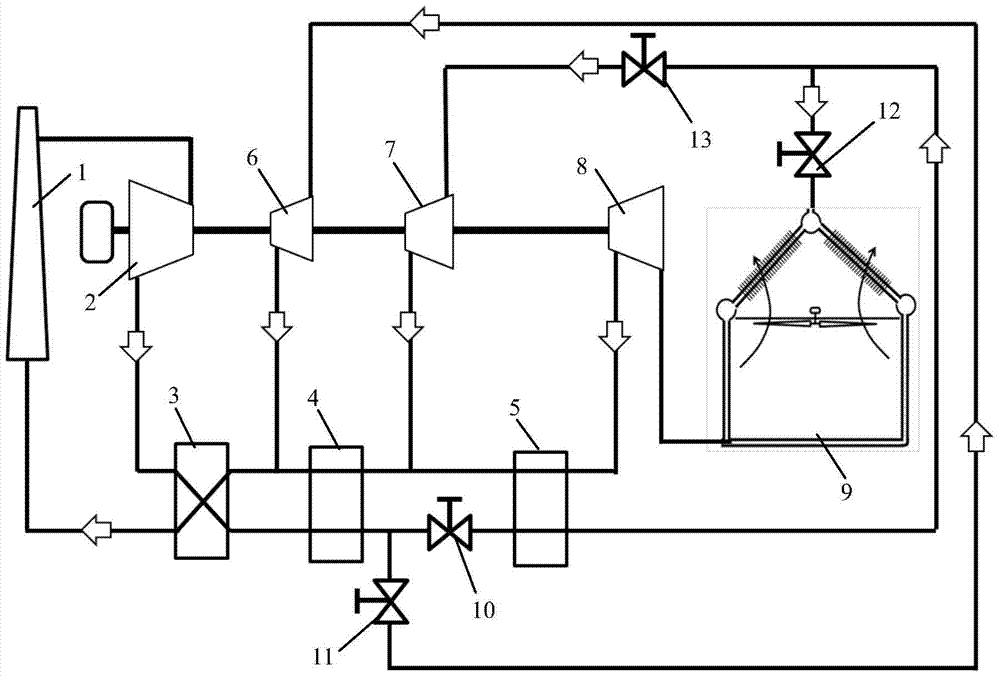

[0016] Tower solar absorber 1 will operate with working fluid CO at a pressure of 20MPa 2 Heated to an operating temperature of 700°C. CO at a temperature of 700°C 2 Working fluid enters supercritical CO 2 Expansion work in turbine 2, after outputting electric energy, becomes CO 2When the steam is exhausted, the pressure is reduced to 8.5MPa. Due to the small expansion ratio, the CO 2 The temperature only drops to 587°C. If CO 2 directly into the gas cooler 9, the CO 2 The circulation releases too much heat to the ambient medium, resulting in reduced thermal efficiency.

[0017] In order to improve thermal efficiency, the present invention adopts the method of regenerating CO to recover 2 The heat of exhaust steam. CO 2 The exhaust steam enters the low-pressure side channel of the first regenerator 3 and the second regenerator 4 through the pipeline in turn and releases heat, and the temperature drops to 170°C. Due to the CO in the high-pressure side channel 2 The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com