Connector for flat terminal

A technology of connectors and terminals, which is applied in the direction of connection, two-part connection devices, parts of connection devices, etc., can solve problems such as poor contact, achieve the effect of preventing poor contact and improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

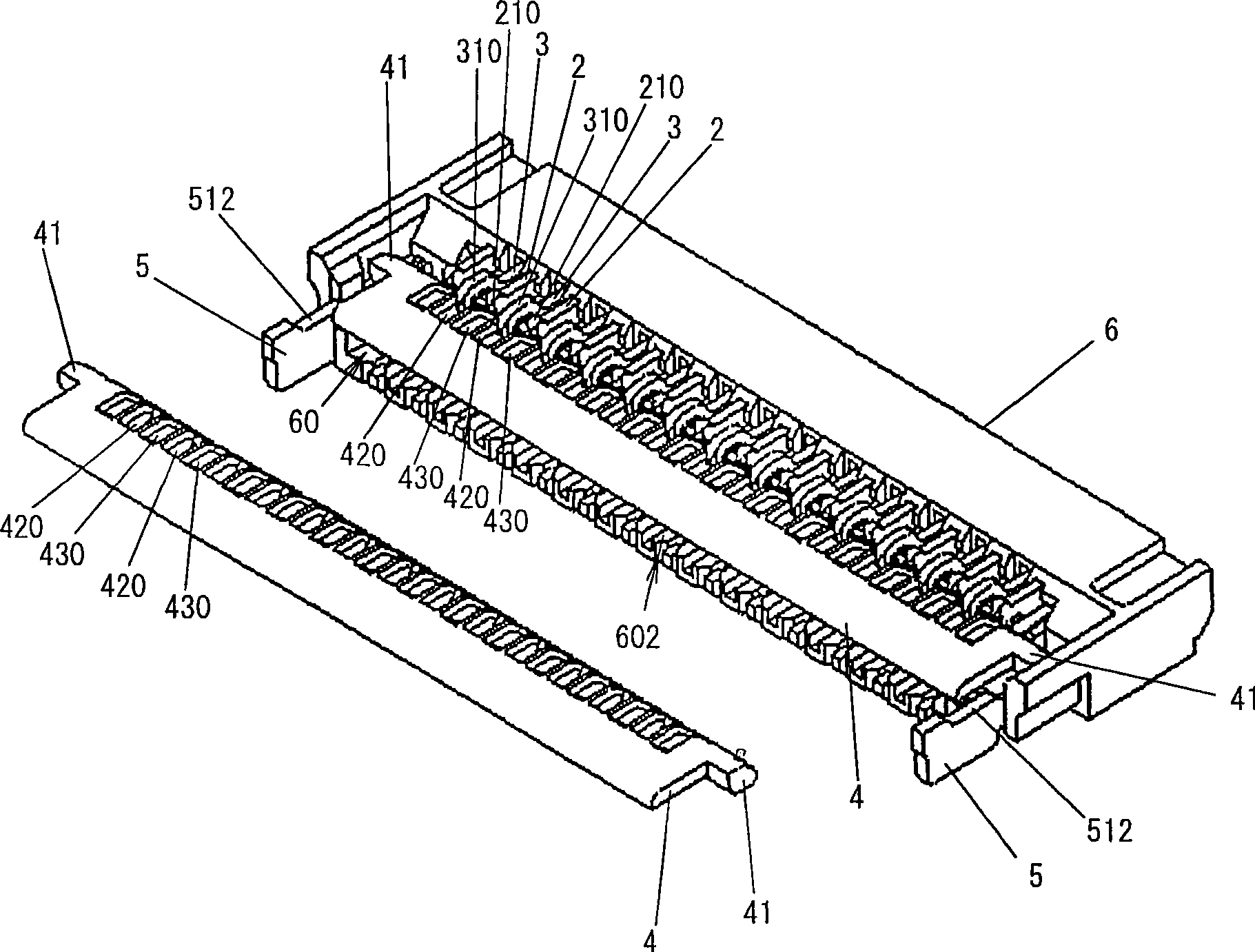

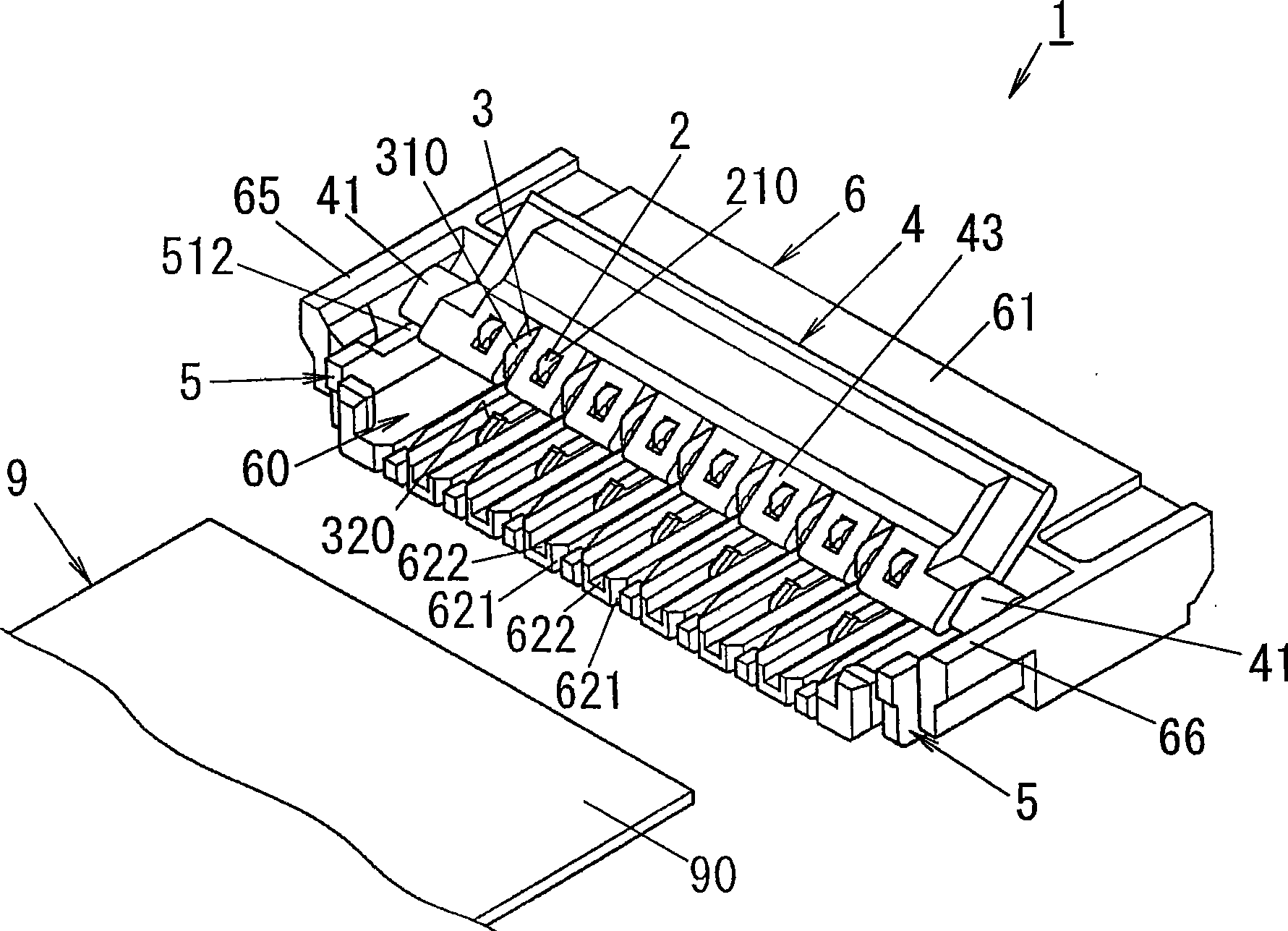

[0027] image 3 A connector for flat terminals according to an embodiment of the present invention is shown. The connector 1 is, for example, an FPC connector connected to the FPC 9, and includes at least one first contact 2, at least one second contact 3, a rod 4 made of synthetic resin, inner plates 5 and 5, and a housing 6 , the housing 6 is made of synthetic resin and has a terminal groove 60 . The shape of the terminal groove 60 corresponds to the flat terminal 90 of the FPC9. However, the flat terminal of the present invention may be one end of a flat flat cable or the like, but is not limited thereto.

[0028] exist image 3In the example of , the connector 1 is provided with eight first contacts 2 and seven second contacts 3 . The first contacts and the second contacts are made of metal, and are alternately arranged between both sides of the terminal groove 60 of the housing 6 .

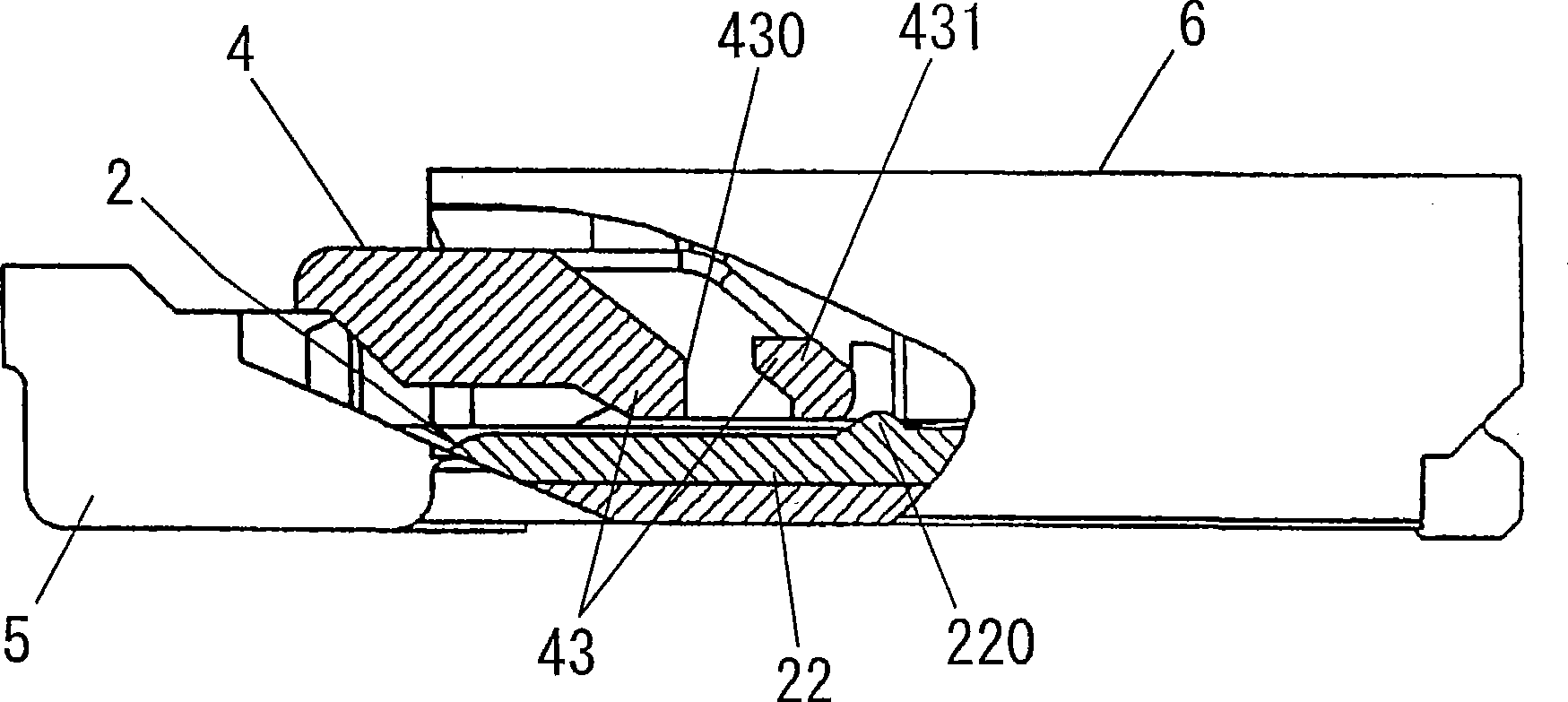

[0029] like image 3 As shown in FIG. 4 , each first contact 2 has a “U” shape and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com