Fluid separation device and fluid separation method thereof

A technology of fluid separation and fluid composition, applied in chemical instruments and methods, centrifuges, analytical materials, etc., can solve problems such as high cost, high manufacturing cost, and complex structure of fluid separation devices, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

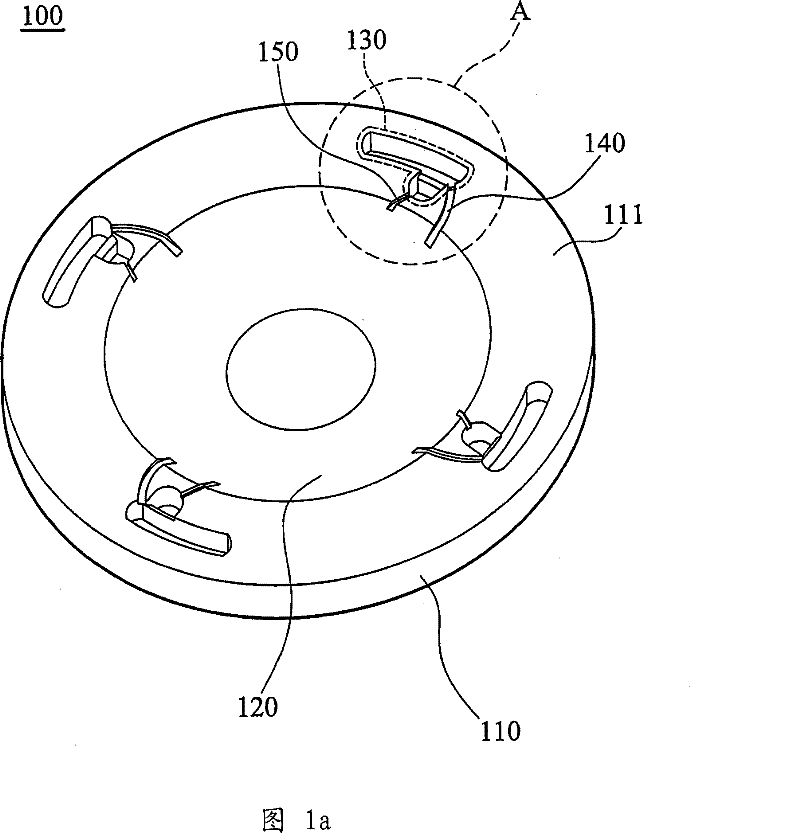

[0029] refer to Figure 1a , which is a fluid separation device 100 showing the first embodiment of the present invention, including a body 110 , a storage tank 120 , a separation unit 130 , a liquid inlet channel 140 and an exhaust channel 150 . The body 110 is circular. The storage tank 120 is circular and is formed in the center of the body 110 . The separation unit 130 is formed on the edge of the body 110 and surrounds the storage tank 120 at equal intervals. The liquid inlet channel 140 is formed on the body 110 and communicates with the storage tank 120 and the separation unit 130 . The exhaust channel 150 is formed on the body 110 and communicates with the storage tank 120 and the separation unit 130 .

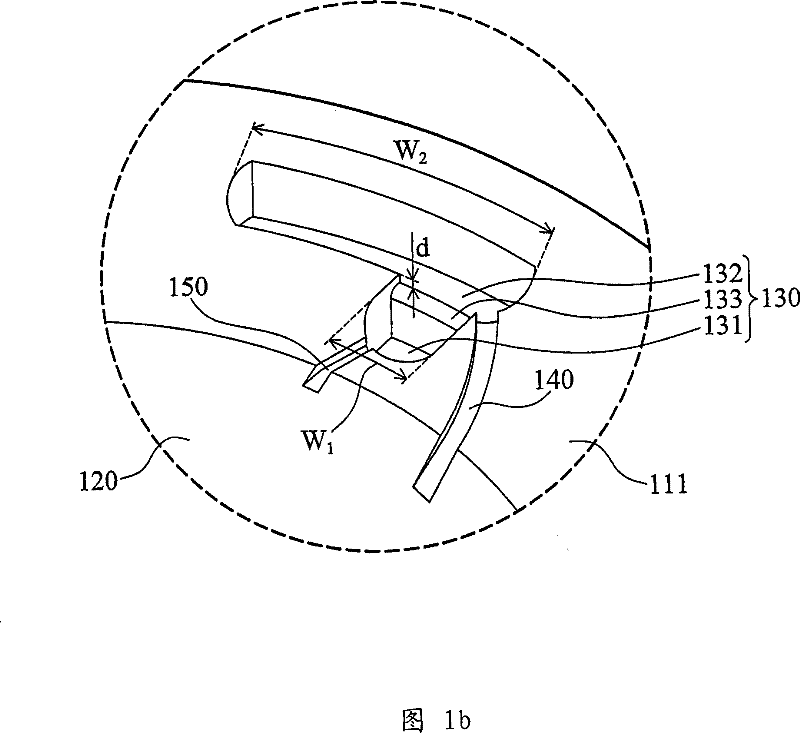

[0030] refer to Figure 1b , which is displayed Figure 1a Enlarged view of part A in . The body 110 includes a first surface 111 . The separation unit 130 includes a collecting area 131 , a stacking area 132 and a blocking wall 133 . The collection area 131 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com