Blockage of sealing oil sump duct and blockage method thereof

A technology of sealing oil and shell oil, which is applied in the direction of engine sealing, engine lubrication, engine components, etc., and can solve the problems of complicated oil pan processing, oil leakage, oil seepage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

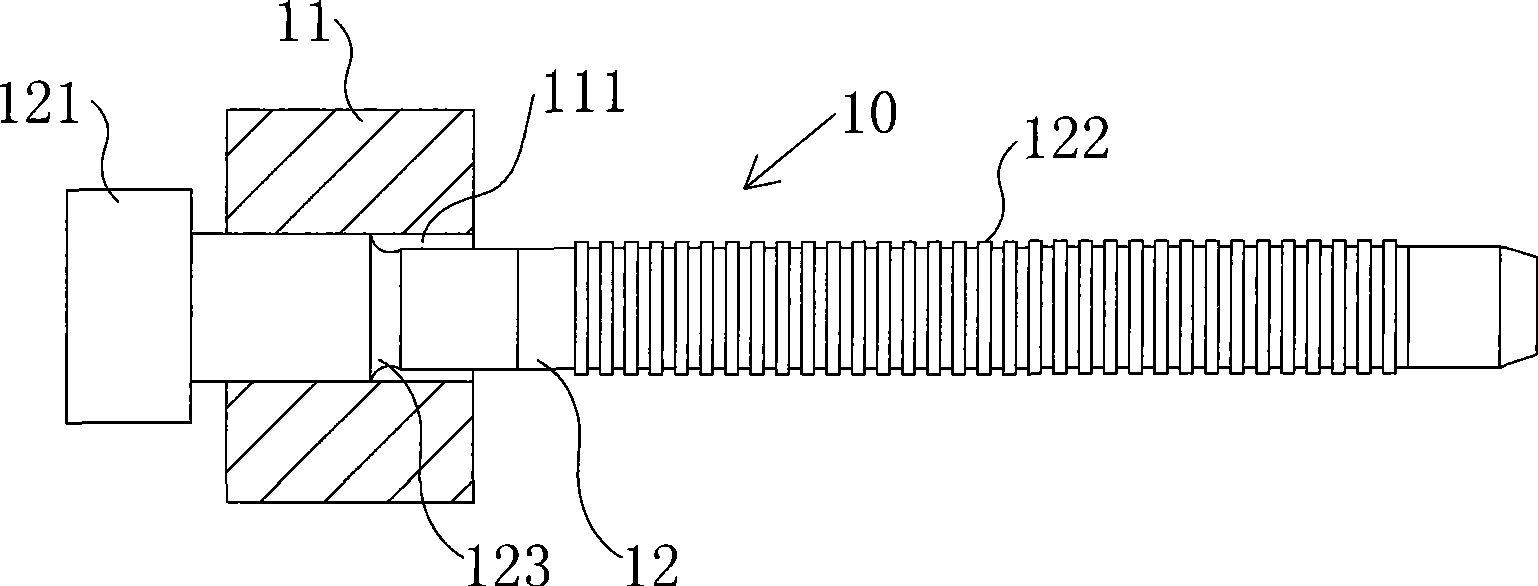

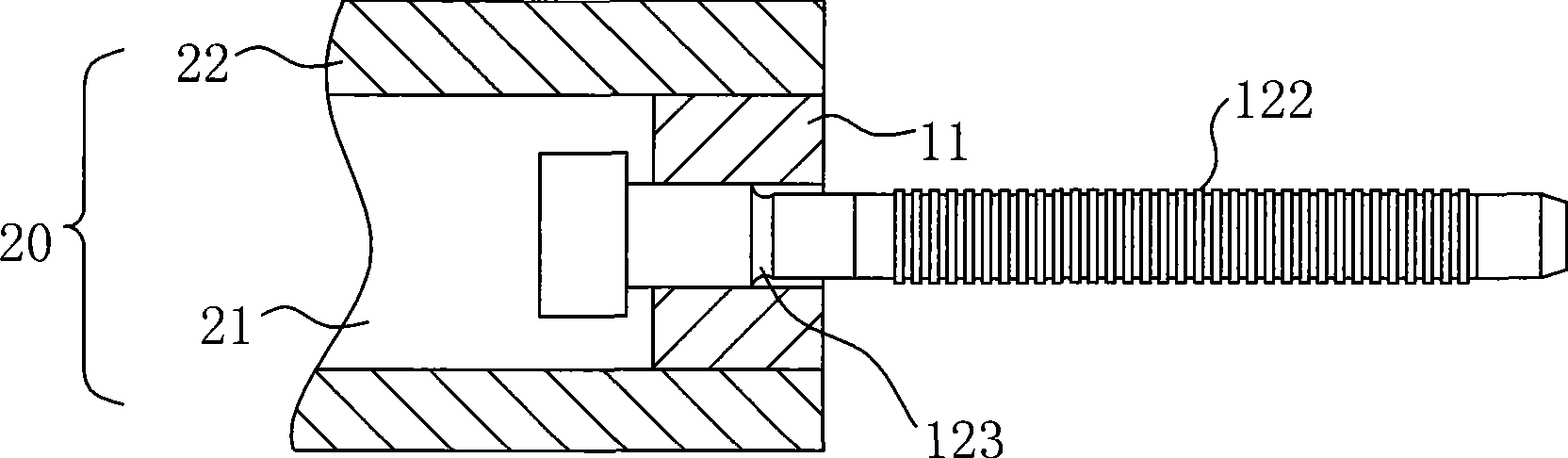

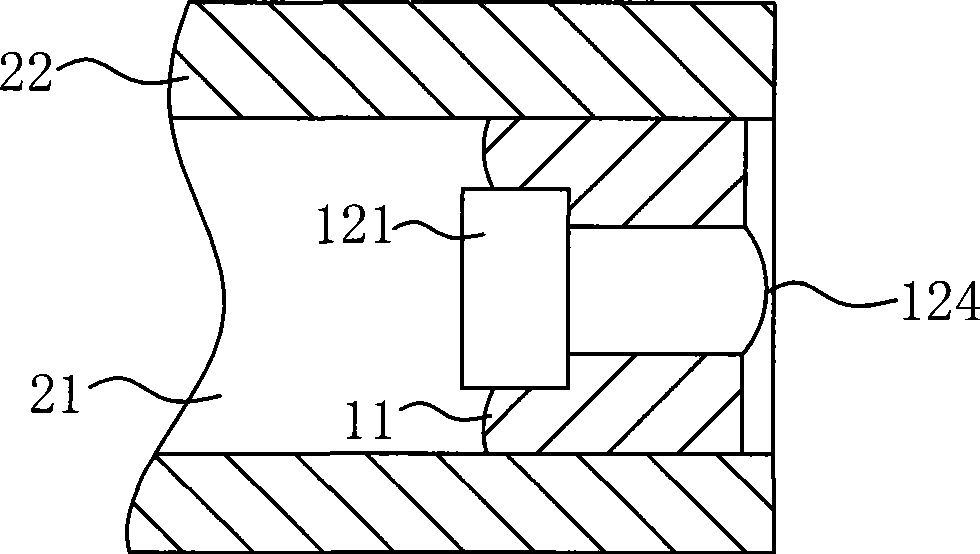

[0012] A kind of blockage for sealing the oil channel of the oil pan, the blockage is a blind rivet 10, the blind rivet 10 is composed of two parts, one part is a hardened carbon steel rivet core 12, and the other part is a fully annealed aluminum cap body 11, the radial dimension of the cap body 11 is smaller than and close to the size of the oil passage hole 21, the dimensional tolerance of the oil passage hole 21 is 0-1.5mm, and the center position of the cap body 11 is provided for the rod body 122 of the rivet core 12 to pass through. through the through hole 111, the direction of the through hole 111 is consistent with the rod length direction of the rod body 122, and the diameter of the rod body 122 in the through hole 111 changes from large to small, and the diameter change should be completed in a shorter length range to ensure reliable realization break, and the overall length of the part is correct. The diameter reduction part is provided with a fracture part 123 al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com