Multifunctional perforating machine set

A multi-functional and unit technology, applied in the direction of metal rolling stands, metal rolling mill stands, driving devices for metal rolling mills, etc., can solve the problem of large investment, achieve simple equipment structure, save investment, and facilitate disassembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

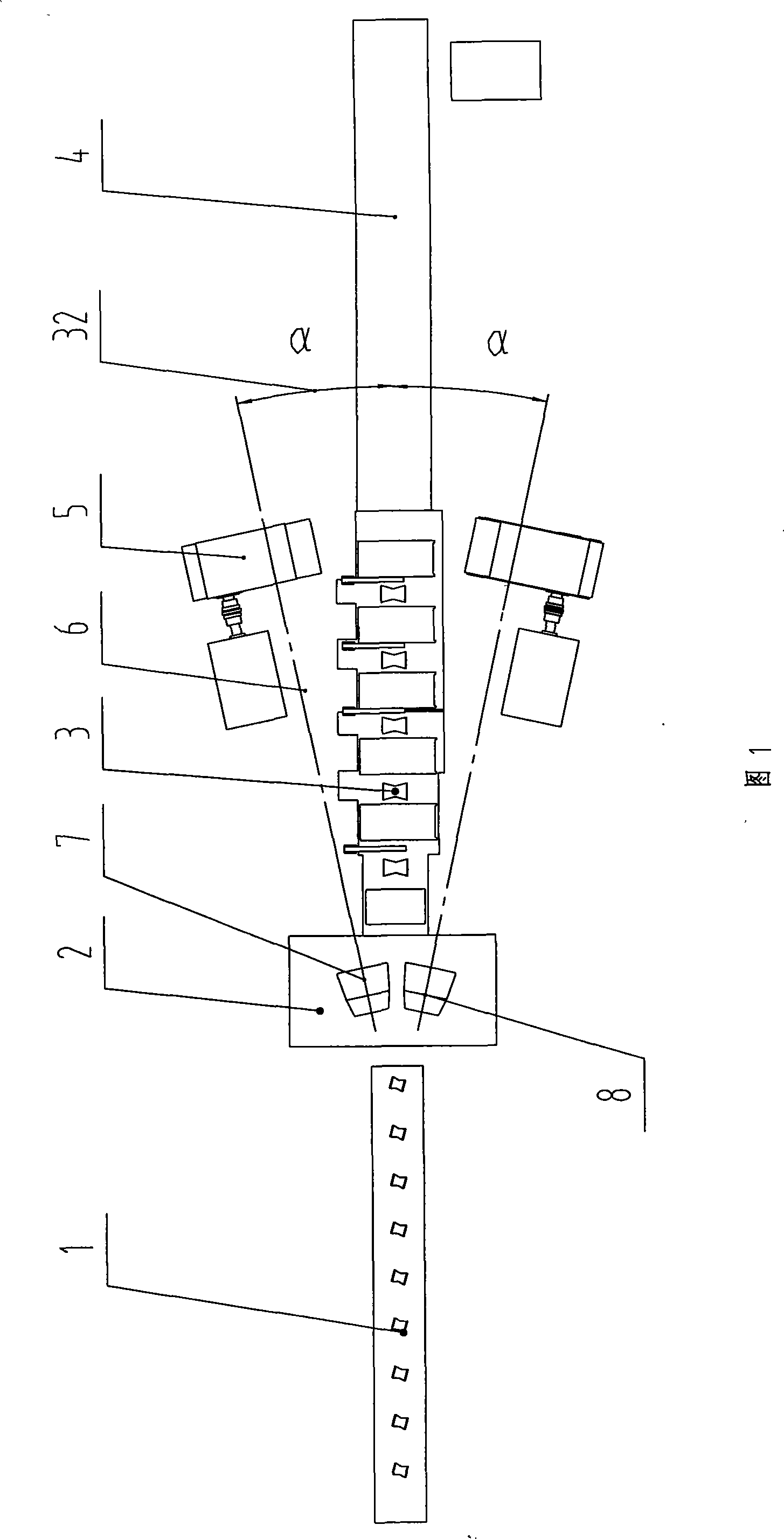

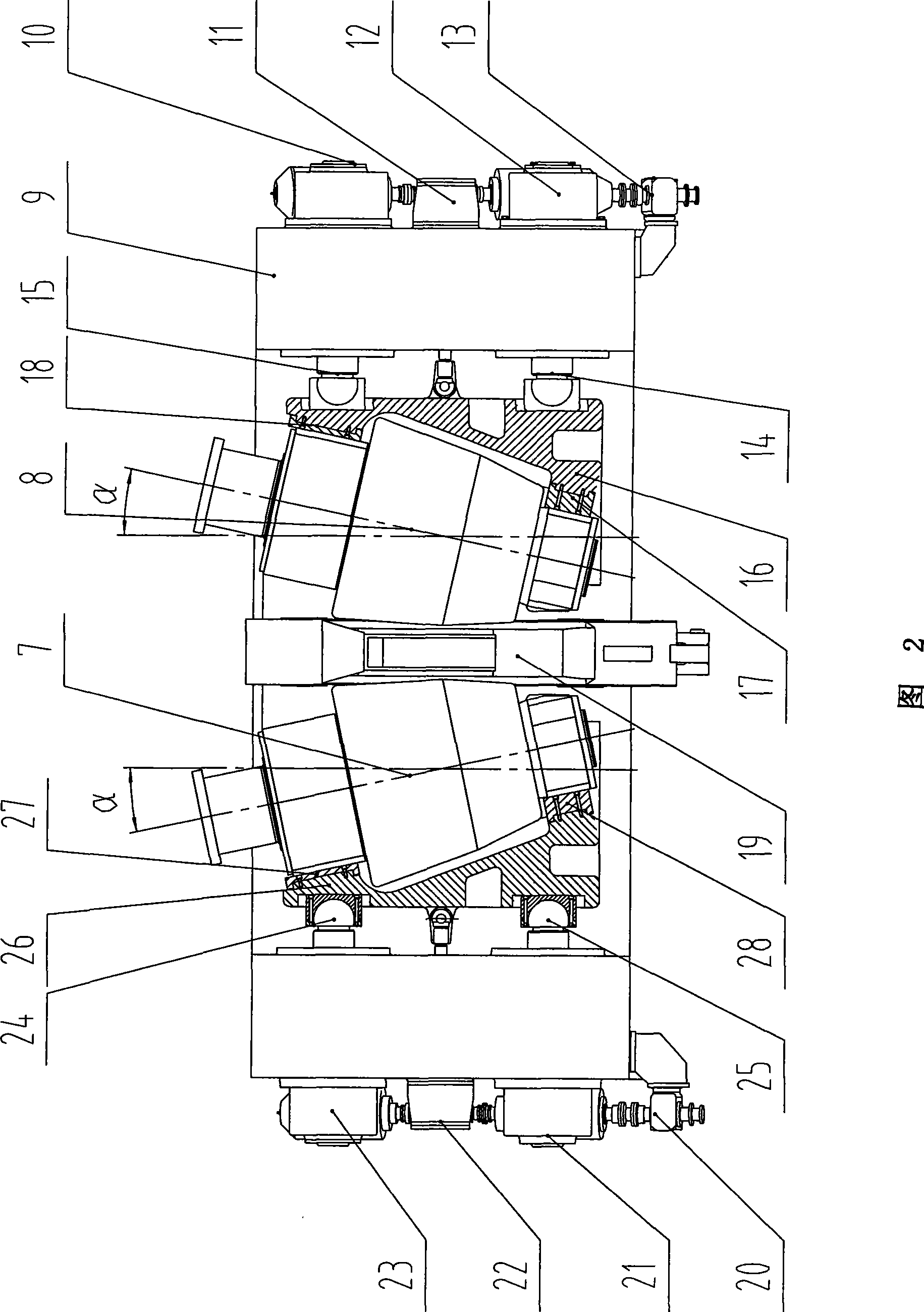

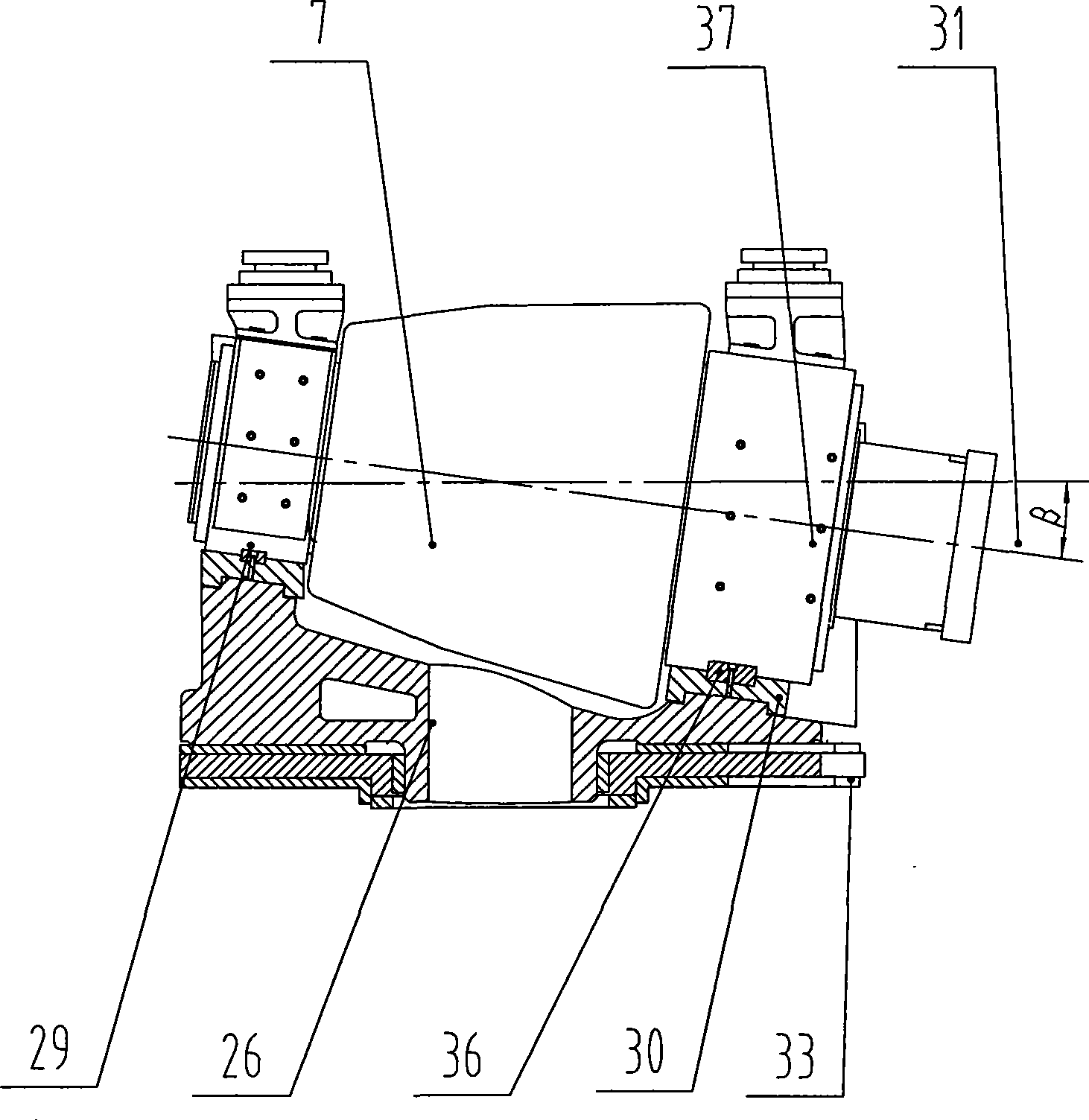

[0013] A multi-functional piercing unit, comprising a front desk 1, a main machine 2, a back stage section 3, and a backstage second section 4, the main transmission 5 is connected with the first roll 7 in the main machine 2 through a universal coupling 6, and the first roll 7 Set on the L-shaped first roll box 26, another main drive is connected with the second roll 8 in the main machine through another universal coupling, the second roll 8 is set on the L-shaped second roll box 16, Between the outer end of the big-end roll chock 37 of the first roll 7 and the L-shaped first roll box 26, a first large-end wedge-shaped spacer 27 is movably arranged, and on the outside of the small-end roll chock of the first roll 7 Between the end and the L-shaped first roll box 26, a first small-end wedge 28 is movably arranged, and the thicknesses of the first large-end wedge 27 and the first small-end wedge 28 adjusted can realize rolling respectively. Angle a is the adjustment of 6 °, 12 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com