Torque control system of electric bar plate clamp

A technology of torque control and slab, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high temperature, large starting current, large impact on the transmission system, etc., to reduce damage factors, reduce failure rate, Guaranteed safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

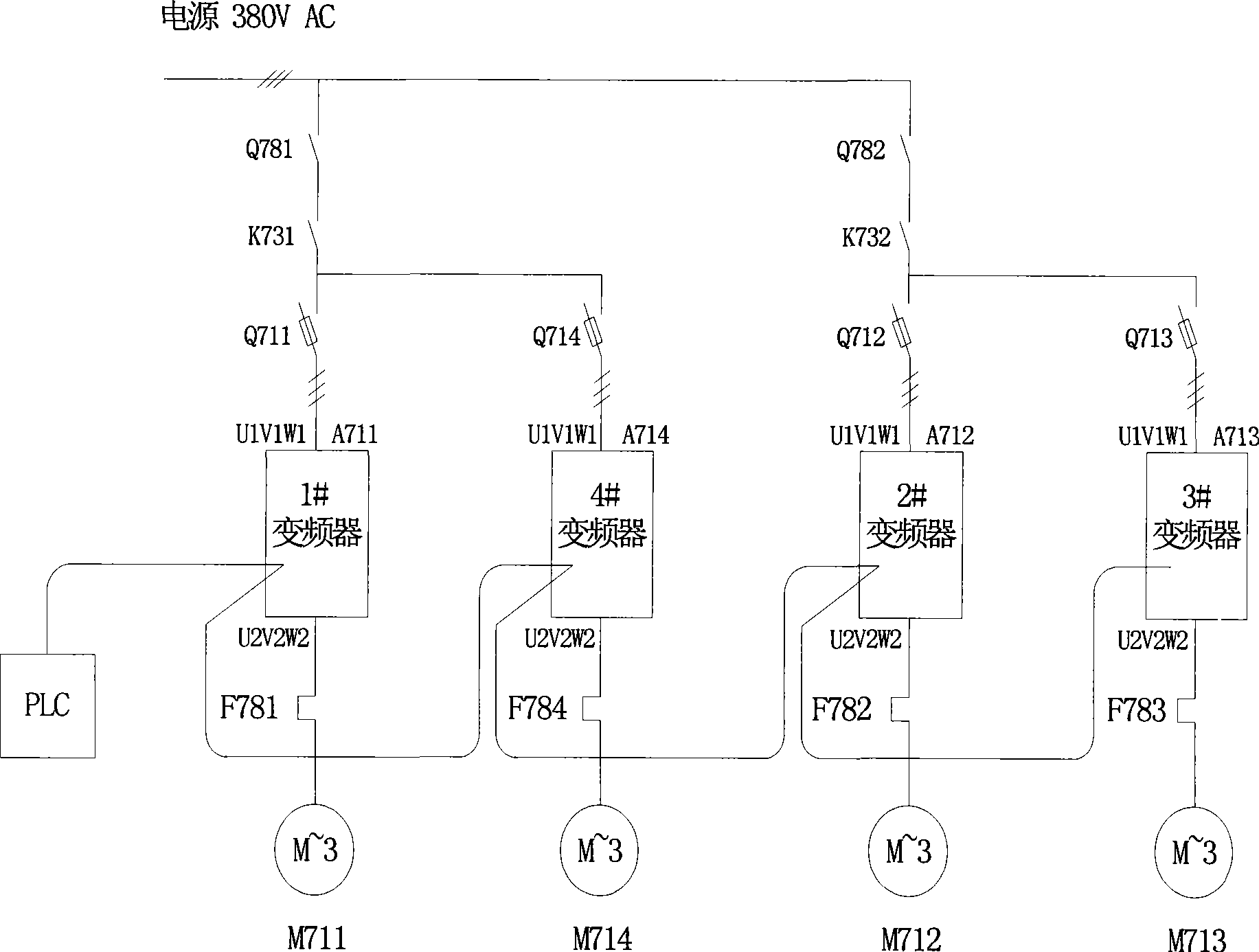

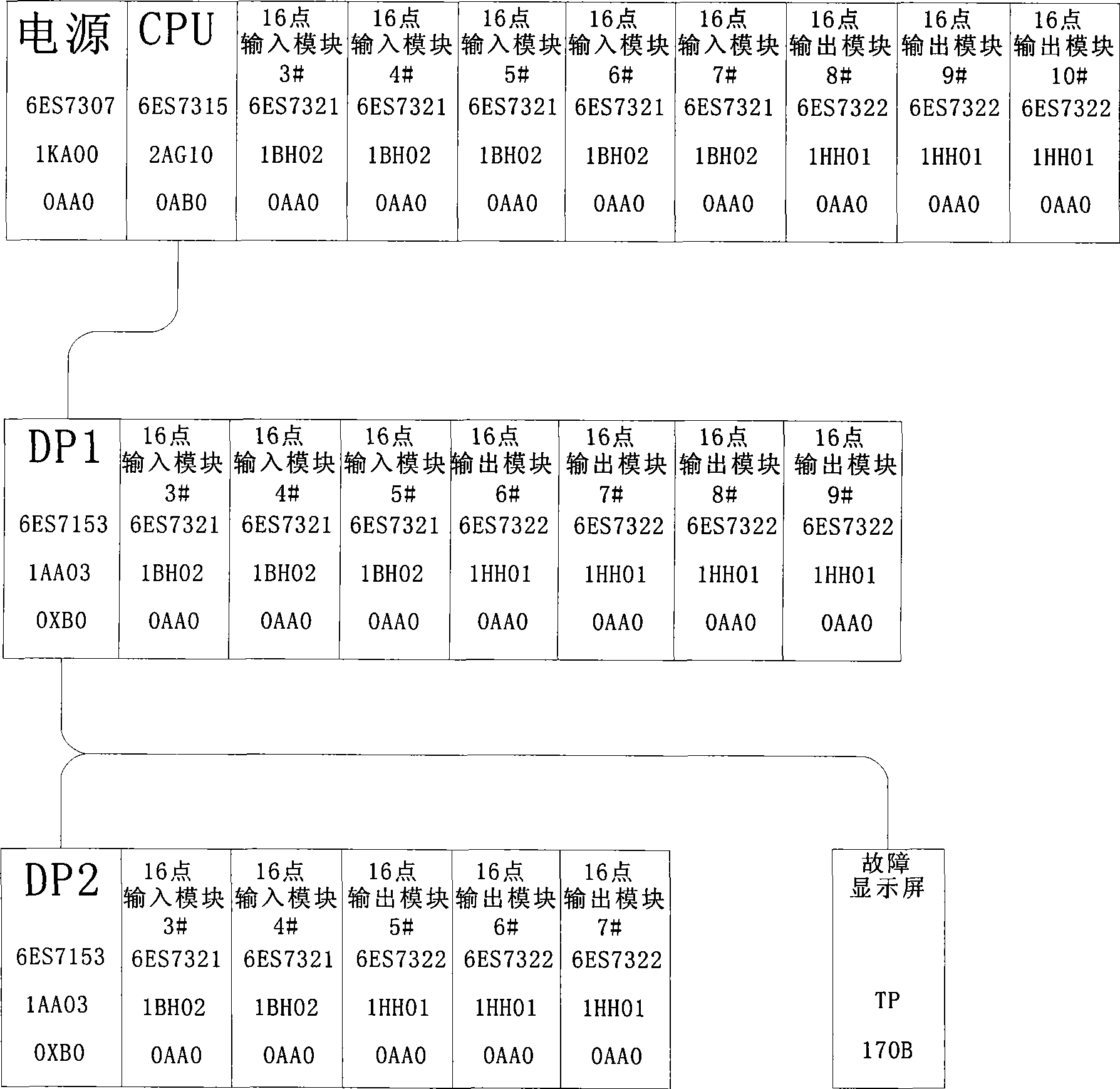

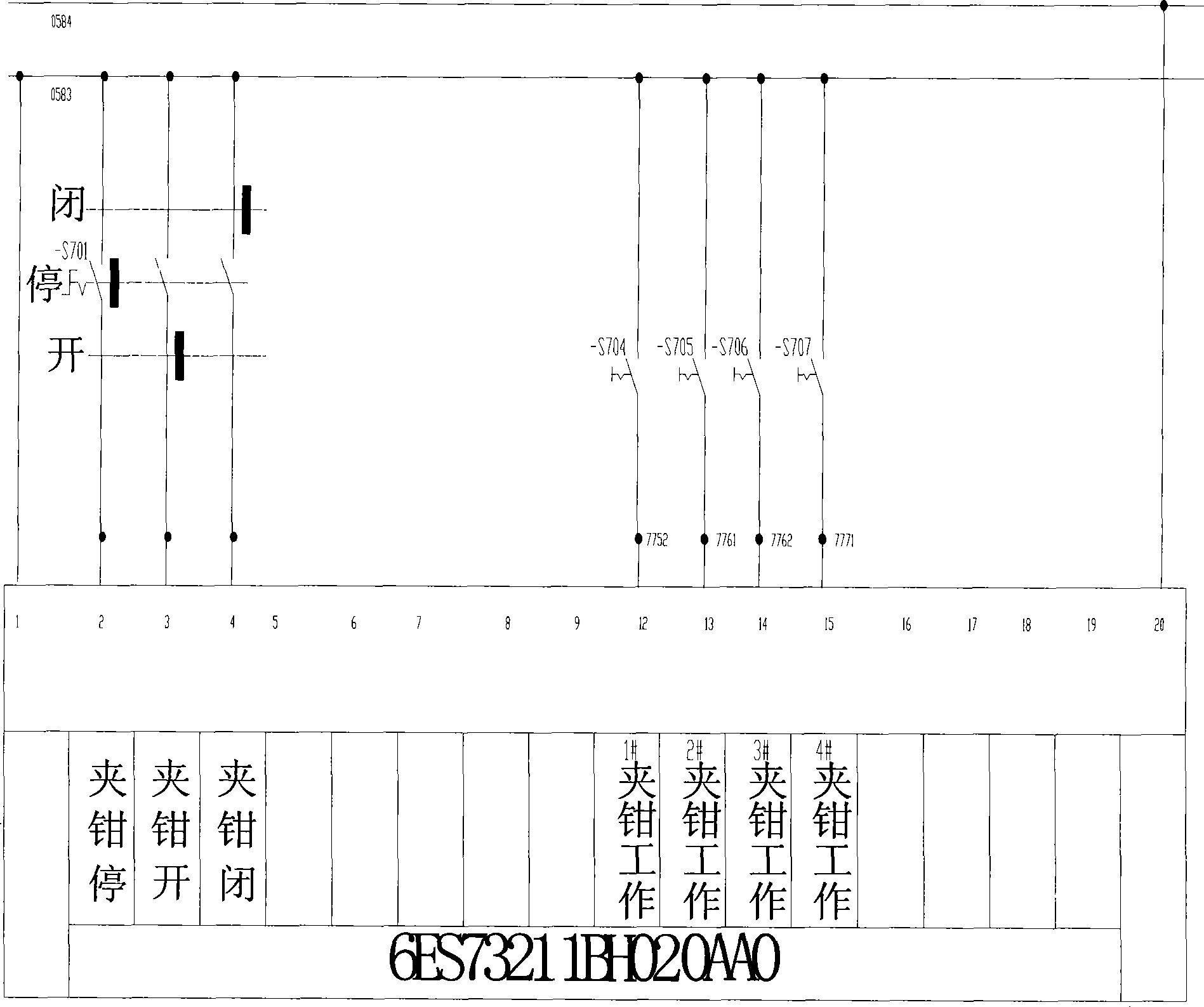

[0013] like figure 1 As shown, a torque control system for electric slab tongs includes a clamp body actuator and a corresponding motor, and is characterized in that it also includes a PLC and a frequency converter corresponding to the motor. The actuator of the clamp body is directly connected to the The corresponding motor shafts are connected, and the output end of the PLC is connected to the control input end of the frequency converter to complete the control of the output torque of the frequency converter. The power input end of the frequency converter is connected to the power supply through a fuse and a contactor. The power output terminal is directly connected to the power supply terminal of the corresponding motor to control the rotation direction and torque of the motor, and the input terminal of the PLC is connected to the operation control button....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com