Method for detecting working temperature of valve

A technology of working temperature and valve, applied in the field of temperature measurement, can solve the problems of complexity, high cost of measurement, and inability to measure the distribution of valve temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, a method for measuring valve temperature, is characterized in that: mainly comprises the following steps:

[0019] A. Make samples, use X45CrSi93 to make exhaust valves, and make 150 small samples of bars of the same material and furnace number at the same time, and perform heat treatment at the same time, only quenching without tempering, to ensure that the quenching hardness of the valve is consistent with that of the small samples ;

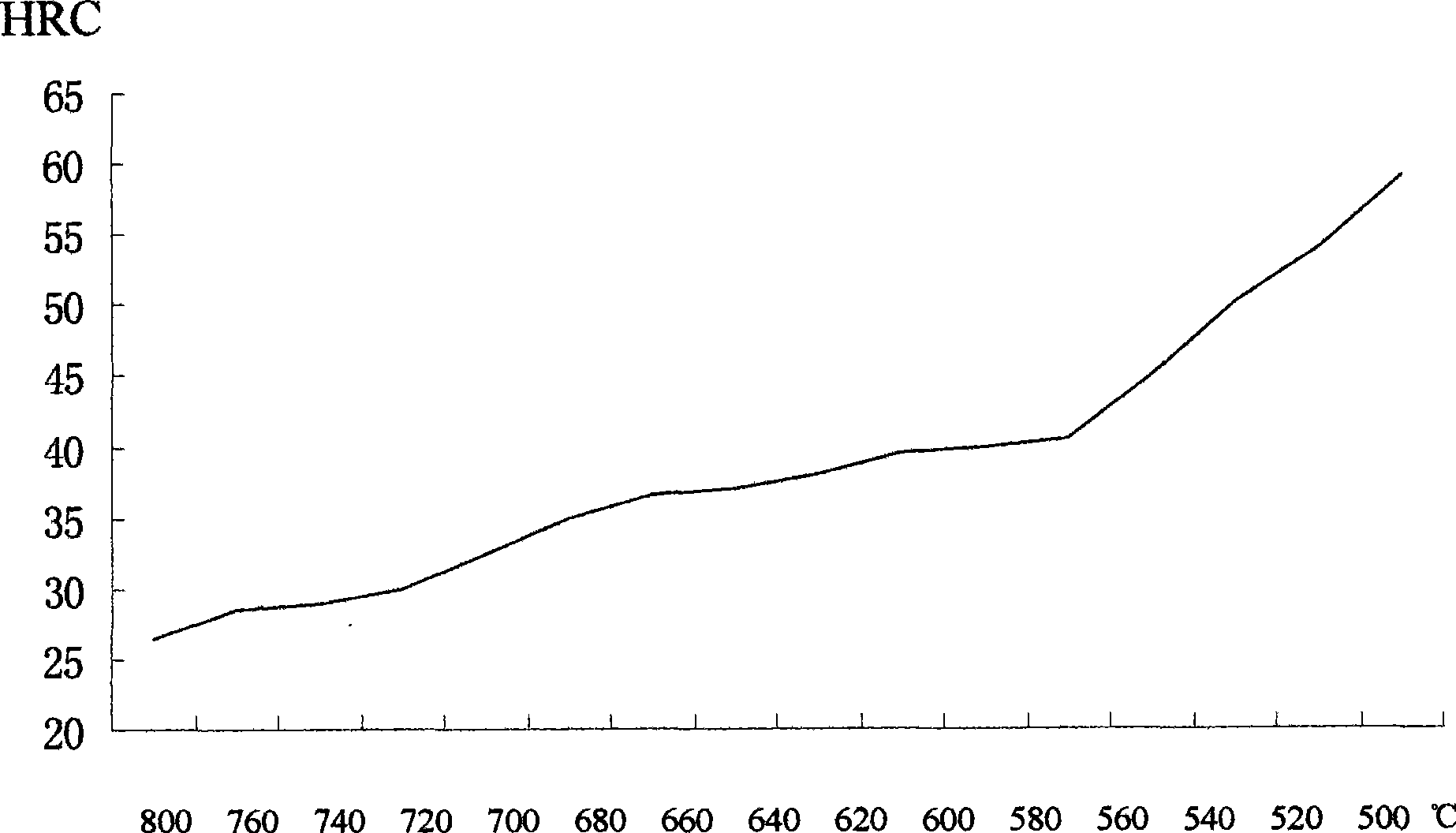

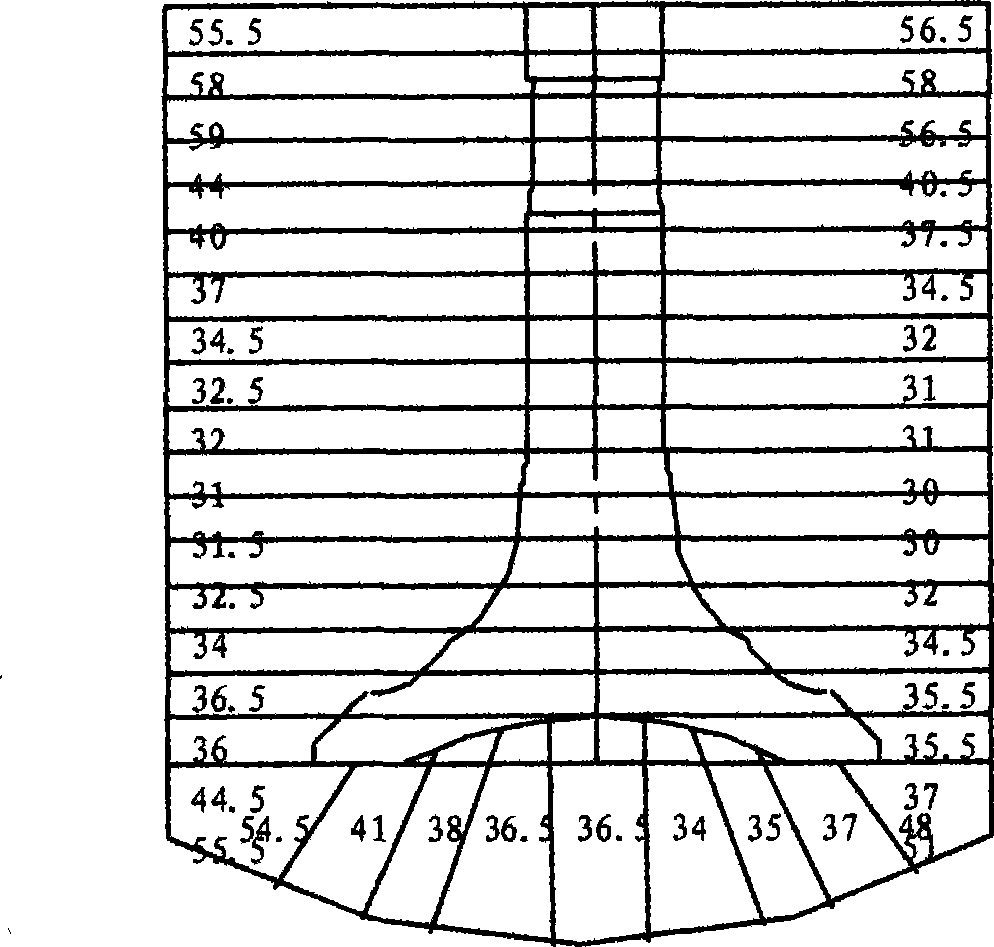

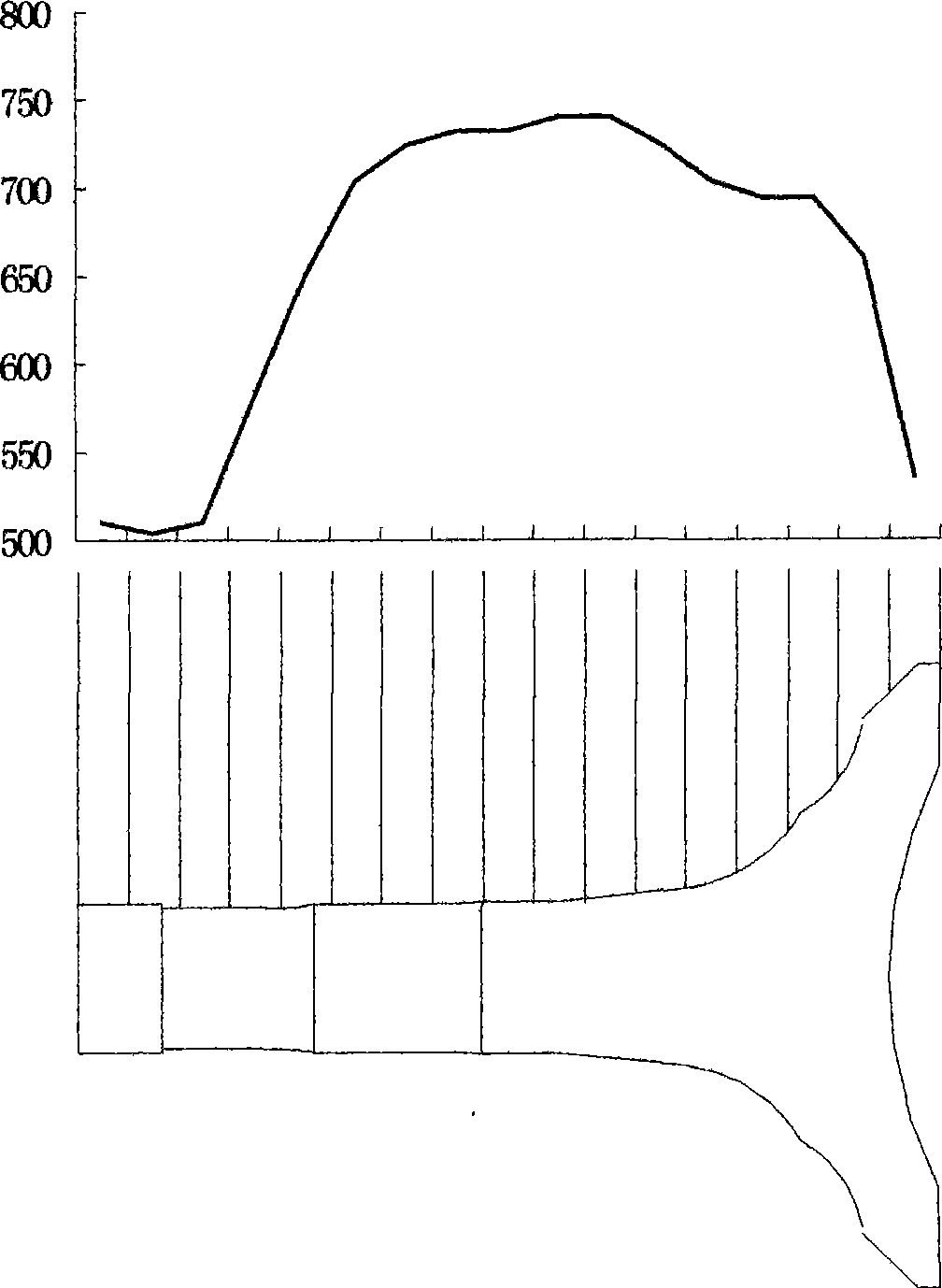

[0020] B. Temper the small samples of the bar at different temperatures, measure the hardness, and draw the tempering temperature-hardness correlation curve: put the small samples of the bar in groups of 3, within the range of 480--800°C, According to the temperature difference of 20°C, the tempering time is respectively carried out at different temperatures for 2 hours, and then the plane is ground on the grinding machine, and the hardness is tested. The hardness of each bar at the temperature varies with the furnace num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com