Antimicrobial socks and method for producing the same

A technology for sock and hygienic finishing, applied in the field of antibacterial, can solve the problems of non-wearability of the outer layer and uncomfortable wearing, and achieve the effects of lasting antibacterial, good antibacterial effect and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

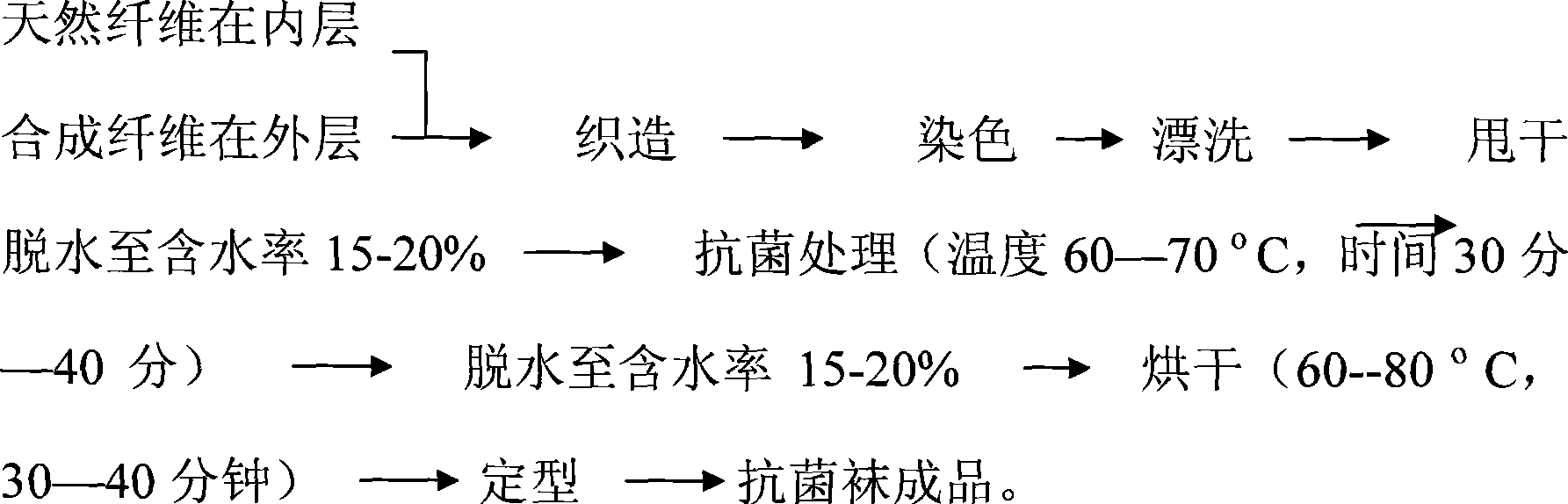

Method used

Image

Examples

Embodiment 1

[0017] 32-count carded cotton yarn is used as the bottom thread, nylon yarn is used as the upper thread, and 40 grams of socks with cotton inner layer and polyester outer layer are woven. After soaking 500 pairs of socks of 40 grams with clear water, the water is dried to make the moisture content of the blanket 15%. . 200 kilograms of water are placed in the finishing tank, and the water is heated to 65 ℃. By weight percentage, the consumption of the antibacterial sanitation finishing agent WS-8810 is 6% of the blanket weight, i.e. 1200 grams. Add the quantitative antibacterial sanitation finishing agent WS-8810 into water and stir well. Then put the socks to be sorted into the sorting tank, stir for 30 minutes, and keep the temperature at 65°C. Pull out and spin dry so that the moisture content of the socks is 15%, dry them for 40 minutes at a temperature of 70° C., and finally shape them in a setting machine to become a finished product.

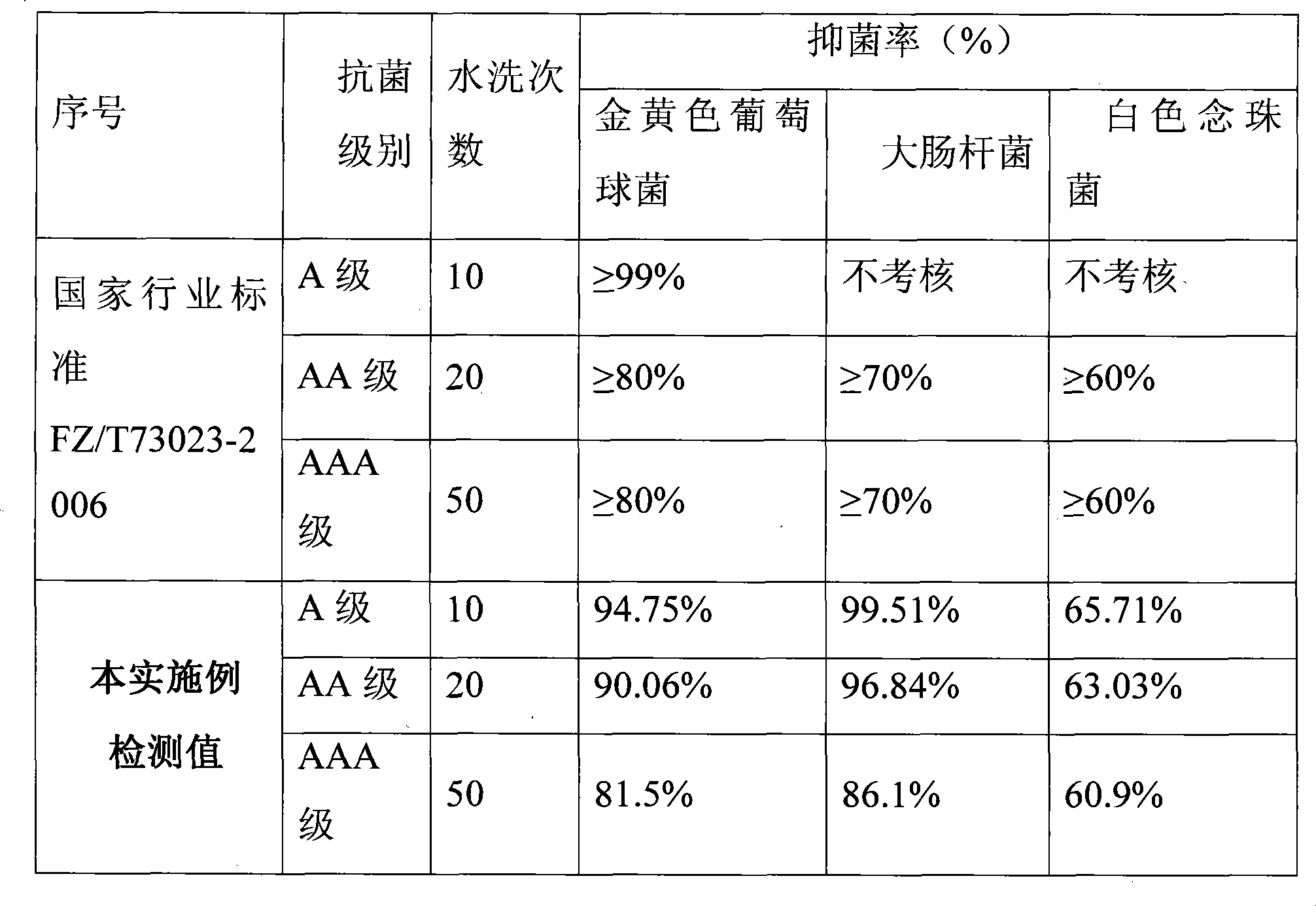

[0018] This embodiment is teste...

Embodiment 2

[0021] 40 counts of combed cotton yarn is used as the bottom thread, polyester yarn is used as the upper thread, and 28 grams of socks with cotton inner layer and polyester outer layer are woven. After soaking 800 pairs of socks of 28 grams with clear water, the water is dried to make the moisture content of the socks 15%. 224 kilograms of water are placed in the finishing tank, and the water is heated to 65 ℃. By weight percentage, the consumption of the antibacterial sanitation finishing agent WS-8810 is 6.5% of the socks weight, i.e. 1456 grams. Add the quantitative antibacterial sanitation finishing agent WS-8810 into water and stir well. Then put the socks to be sorted into the sorting tank, stir and soak for 30 minutes, and keep the temperature at 65°C, take them out and spin dry, so that the moisture content of the blanket is 20%, and dry at 65°C for 50 minutes. Dry it at 70°C for 40 minutes, and finally set it in the setting machine to be the finished product.

Embodiment 3

[0023] 40 counts of combed cotton yarn is used as the bottom thread, polyester yarn is used as the upper thread, and 20 grams of socks with cotton inner layer and polyester outer layer are woven. After soaking 1000 pairs of socks of 20 grams with clear water, the water is dried to make the moisture content of the socks 15%. 180 kilograms of water are placed in the finishing tank, and the water is heated to 70°C. By weight percentage, the consumption of the antibacterial sanitation finishing agent WS-8810 is 7% of the socks weight, i.e. 1400 grams. Add the quantitative antibacterial sanitation finishing agent WS-8810 into water and stir well. Then put the socks to be sorted into the sorting tank, stir and soak for 30 minutes, and keep the temperature at 70°C, take them out and spin dry, so that the moisture content of the blanket is 20%, and dry at 65°C for 30 minutes, Finally, it is the finished product after being shaped in the setting machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com