Blow molding mold special for clothing prop for stage

A technology for blow molding molds and props, which is applied in the field of blow molding molds for clothing props. It can solve the problems of reduced production efficiency, increased manufacturing costs, and simultaneous molding, and achieves the effects of increasing production capacity, increasing service life, and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

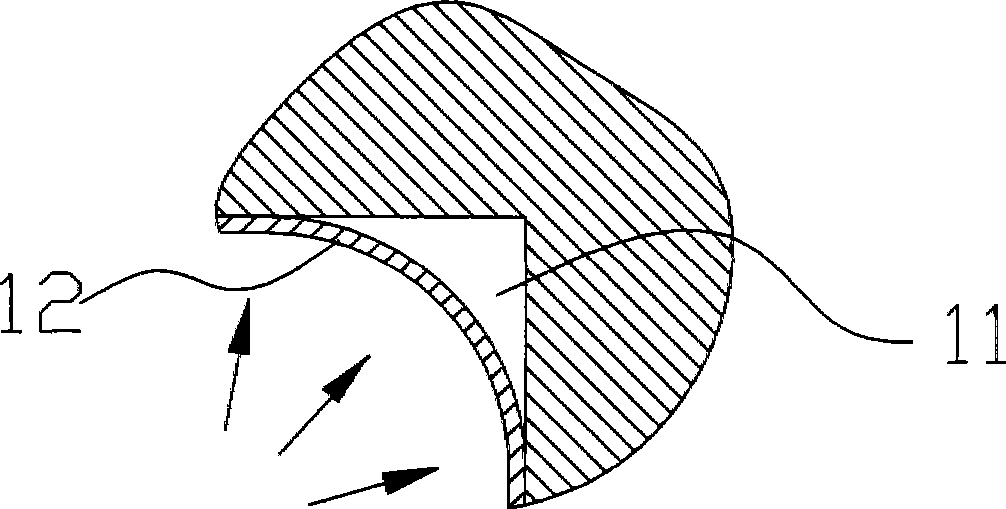

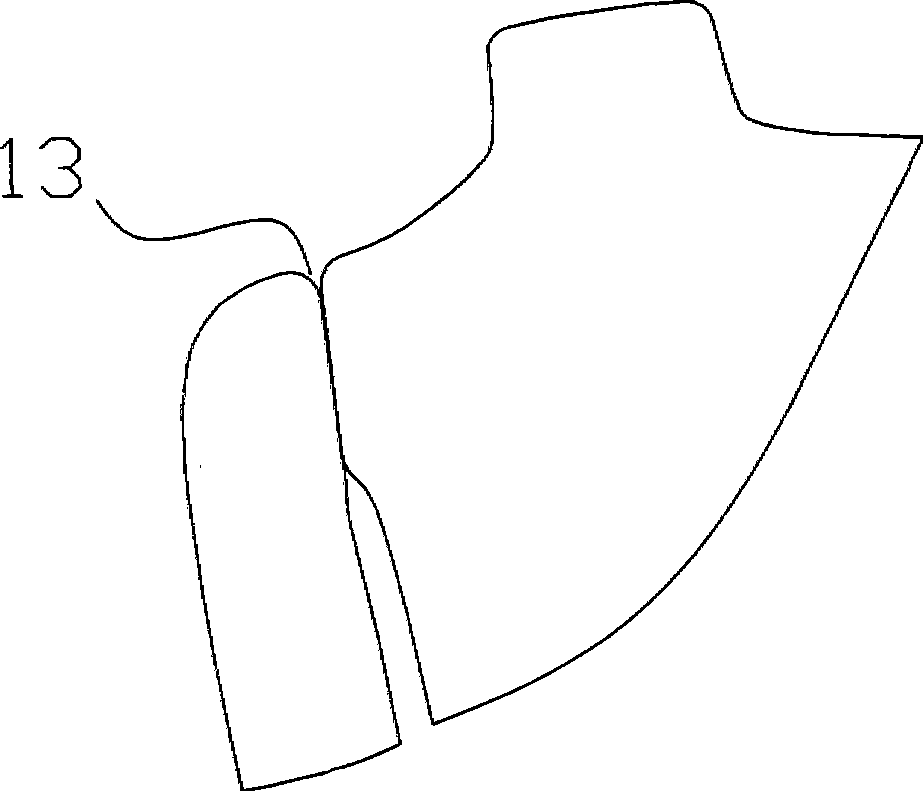

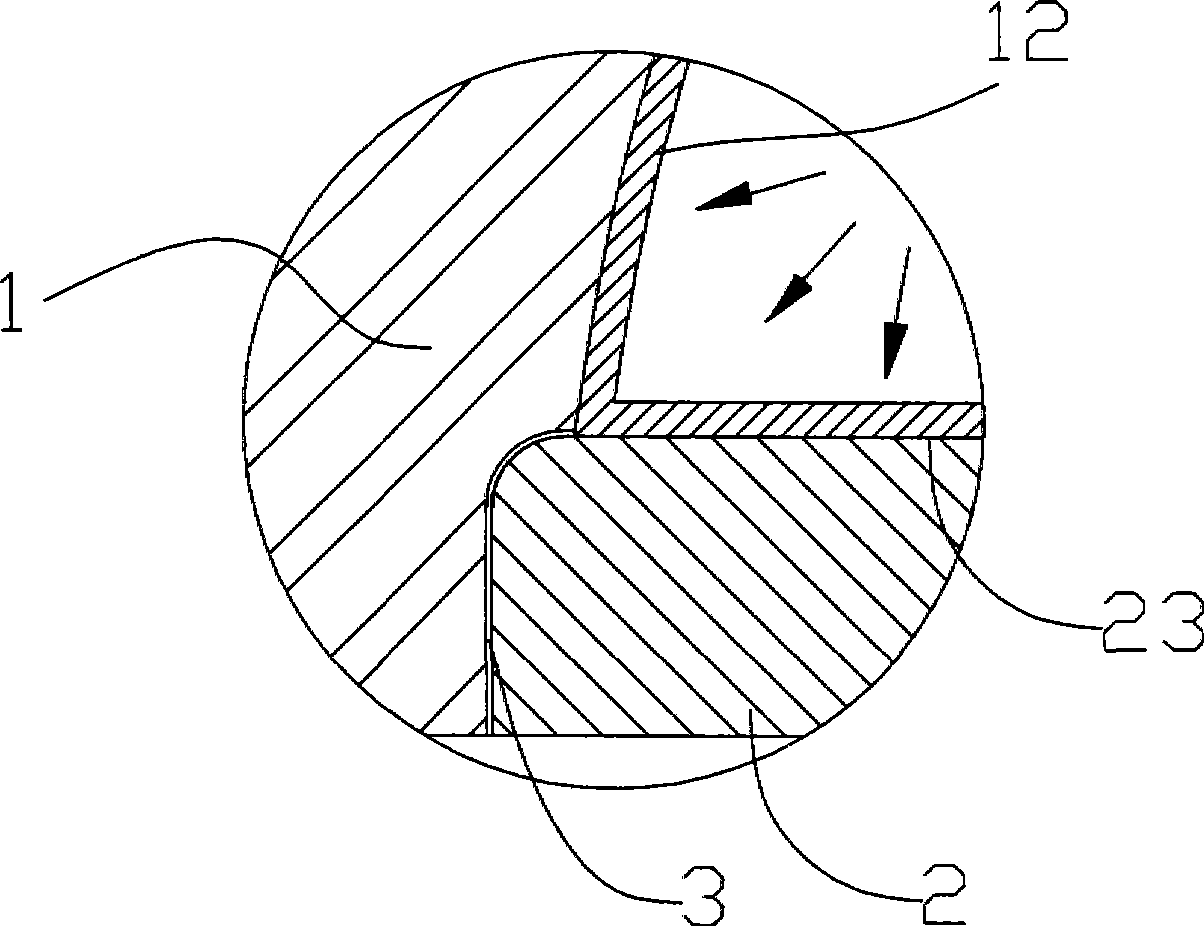

[0027] as attached image 3 , 4 As shown, the blow mold used to form the torso of clothing props in this embodiment includes a cavity 1 for forming the torso, and inserts A, B, C and 2 are inlaid on the cavity 1 where the connection surface needs to be formed. . Taking the insert 2 as an example, part of the surface 23 at the front end of the insert 2 constitutes a part of the molding surface of the mold cavity, and the molding surface 23 on the insert 2 forms a corner of about 90 degrees with the adjacent molding surface of the mold cavity 1. A certain gap 3 is provided at the junction between the cavity 1 and the insert 2 as an exhaust groove. The width of the exhaust groove is about 5 to 25 meters, which is mainly adjusted according to the size of the product and the air pressure. Such as the production of props for clothing models, usually the width of the exhaust groove can be set to 15 meters. exist Figure 4 In the process, under the action of air pressure, the bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com