Flexible combined fixture

A tooling and flexible technology, applied in workpiece clamping devices, auxiliary devices, manufacturing tools, etc., can solve the problems of wasting resources and increasing the cost of raw materials, and achieve the effect of reducing high costs, flexible and convenient disassembly, and quick switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

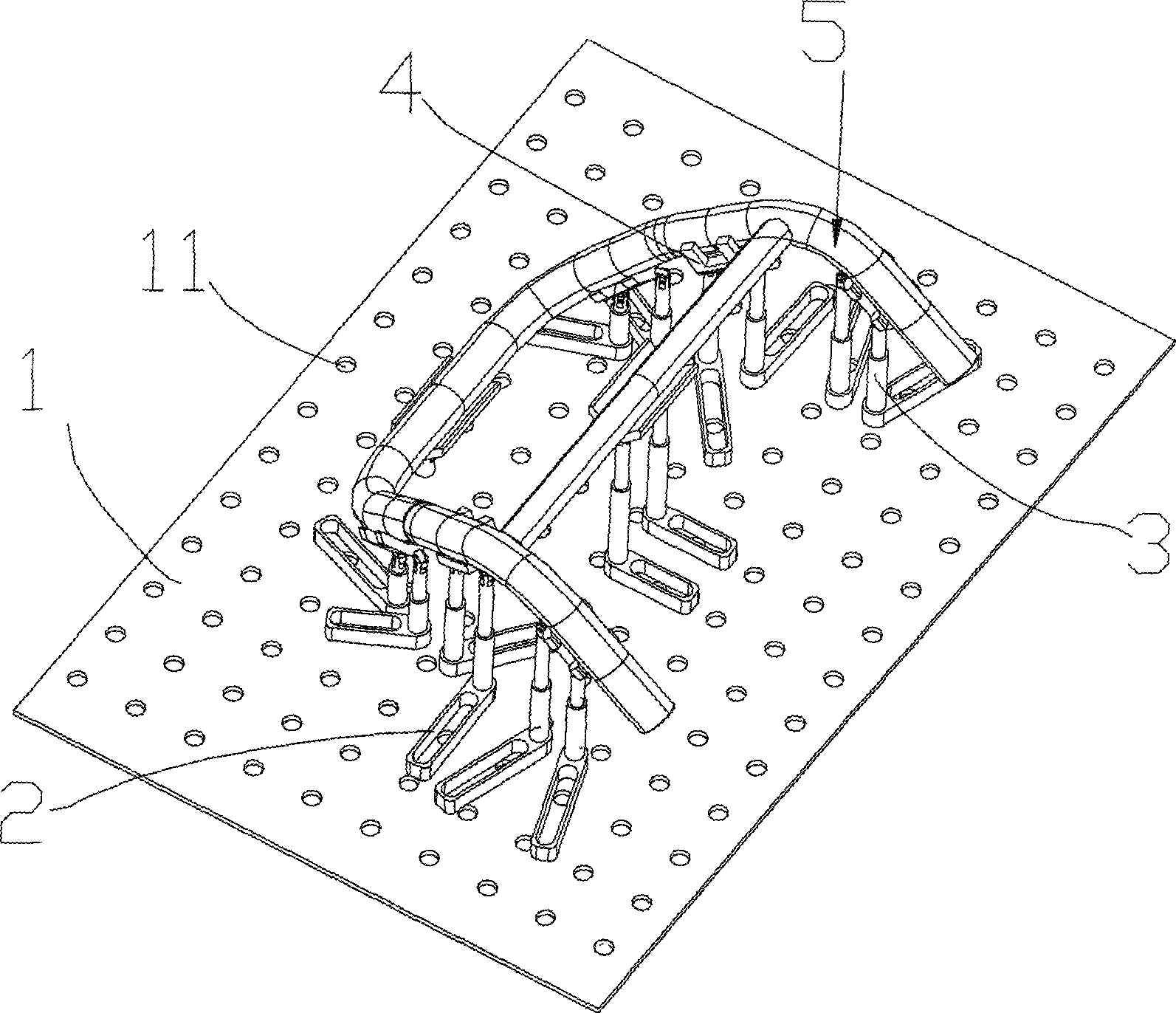

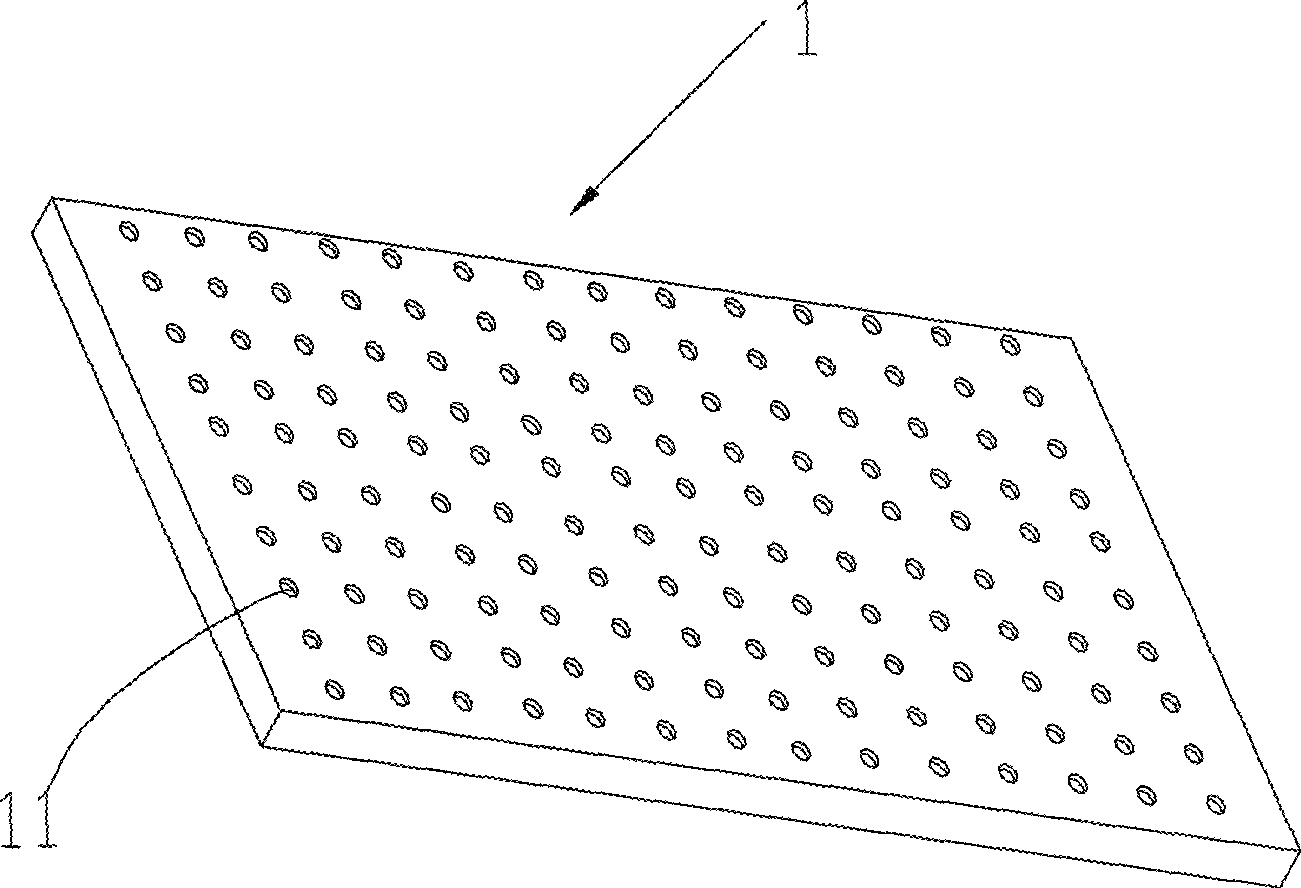

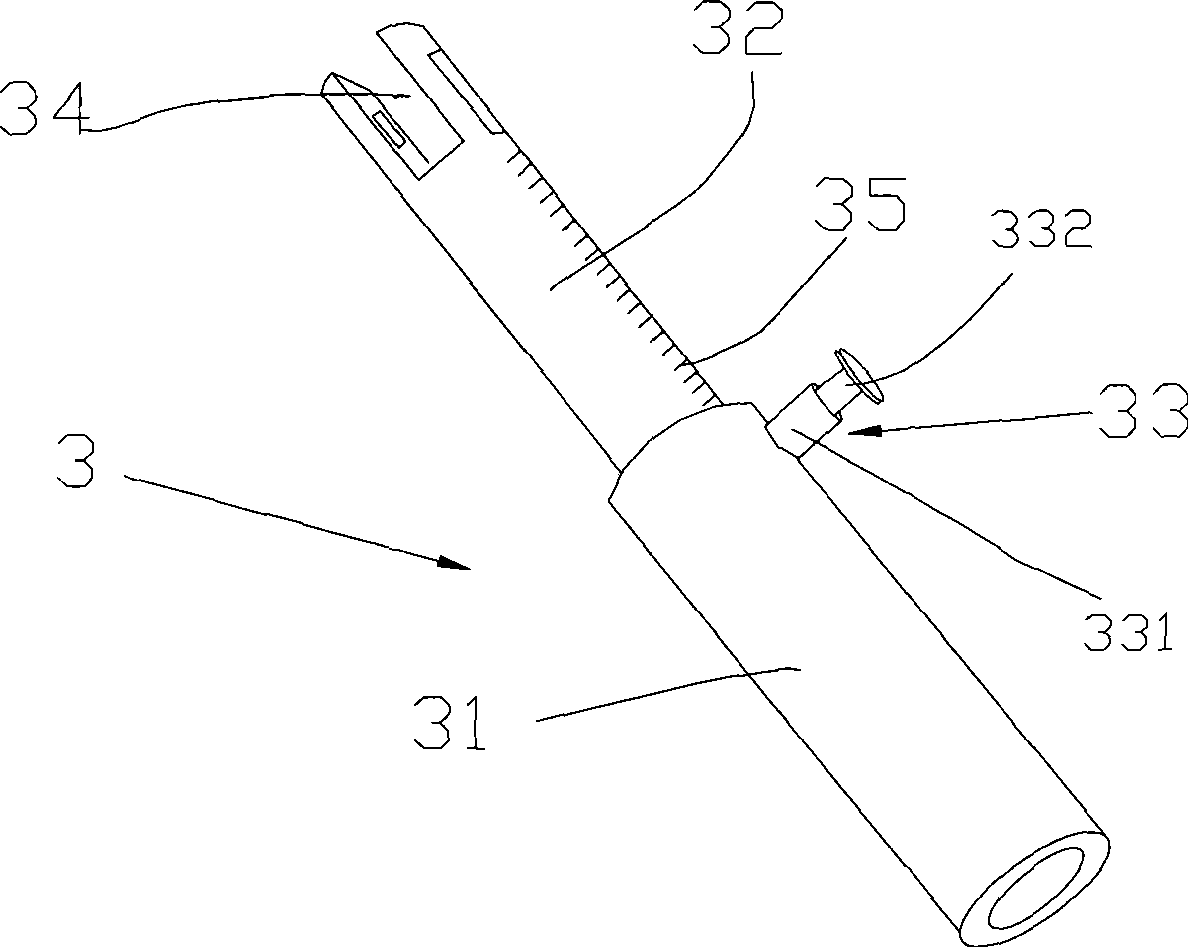

[0028] see Figure 1 to Figure 8 As shown, a flexible tooling includes a workbench 1, a positioning ruler 2, a height positioning rod 3, and a supporting block 4. The workbench 1 is provided with multiple rows of mounting holes 11 vertically and horizontally. The workbench 1 adopts The mesh hole 11 of φ28X100X100mm is used as the base of the tooling, and the maximum size of the table can be designed as 1500X3000, 1500X1200, 1200X1200, which can be selected according to different products;

[0029] The positioning ruler 2 is arranged on the workbench 1, and the positioning ruler 2 is provided with a strip-shaped sliding hole 21 and a positioning round hole 22. The positioning ruler 2 is flexibly connected with the installation hole 11 through the sliding hole 21; The flat ruler 2 can accurately and quickly adjust the positioning position with the workbench 1. In this embodiment, the positioning round hole 22 is set as φ28mm; the positioning flat ruler 2 can determine the plane ...

Embodiment 2

[0037] see Figure 10 As shown, the difference between the present embodiment and the first embodiment is that the vertical cross section of the clamping block 41 is L-shaped, and the L-shaped clamping block can prevent the interference of the elbow, and the structure is simple, convenient and reliable. Other structures are the same as in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com