Underwater pelleting device of machine unit for compounding, squeezing and prilling

A technology of extrusion granulation and underwater granulation, which is applied in the field of mixing extrusion granulation units, and can solve problems such as small output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

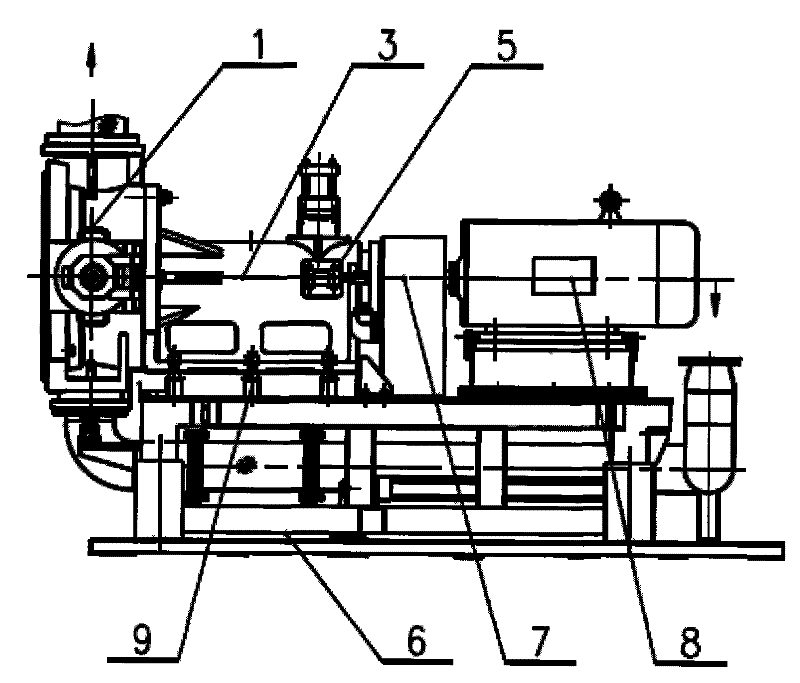

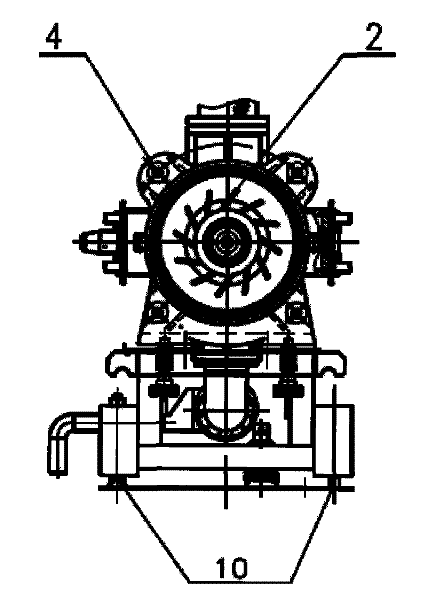

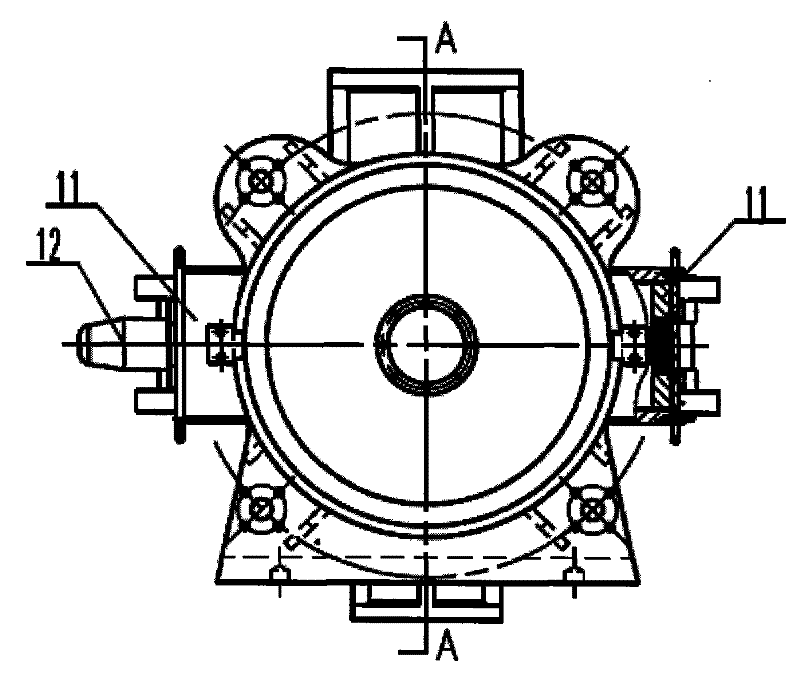

[0025] The underwater pelletizing device of the mixing extrusion pelletizing unit, if attached figure 1 , 2 As shown, it is mainly composed of hot water chamber 1, cutterhead 2, bearing box 3, hot water chamber quick locking mechanism 4, cutter shaft locking mechanism 5, dicing trolley 6, coupling 7, and drive motor 8. Hot water room 1 as attached image 3 , 4 As shown, the body is preferably made of stainless steel castings, which can prevent corrosion by water; its size and shape can not only satisfy the cooling of particles extruded from the template, but also facilitate the flow of cooling water and the efficient transportation of particles; Both sides of the chamber 1 are respectively provided with viewing windows 11, one for placing lighting lamps 12, and one for observation and maintenance, which are used for detection, operation observation and maintenance. Cutter plate 2 as attached Figure 5 , 6 As shown, it is made up of pelletizing knife 17 and tool magazine 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com