Heavy caliber pipe-jacking butt joint technique

A large-diameter, pipe jacking technology, used in pipes/pipe joints/fittings, infrastructure engineering, pipeline laying and maintenance, etc., can solve the problems of complex underground pipelines and different buried depths, and achieve low cost and risk. Market prospects and the effect of shortening the construction period of long-distance pipe jacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, further elaborate the patent of the present invention. It should be understood that these embodiments are only used to illustrate the patent of the present invention and are not intended to limit the scope of the patent of the present invention. In addition, it should be understood that after reading the content taught by the patent of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0037] The large diameter pipe jacking butt joint process of the present invention, its steps are as follows:

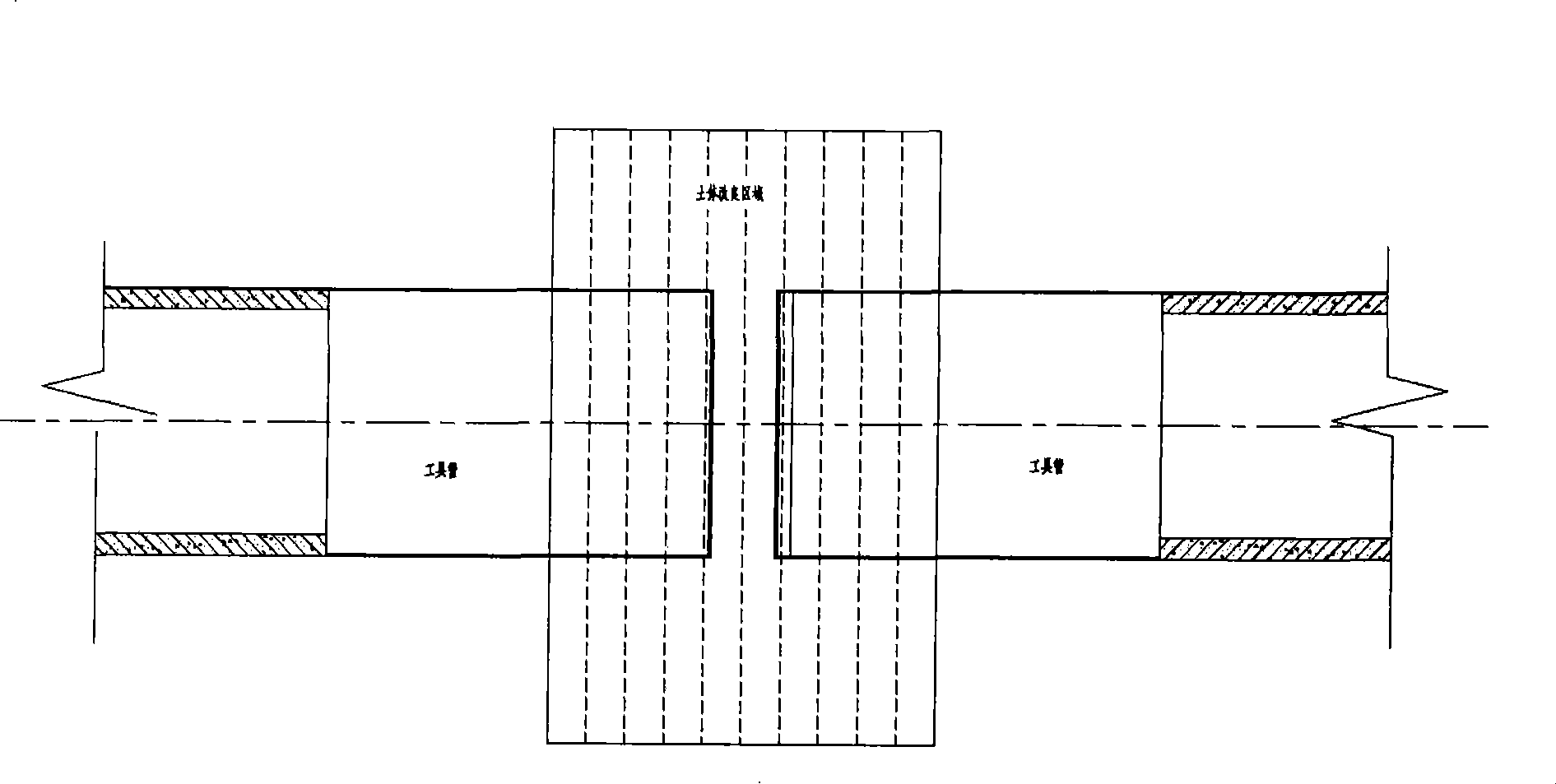

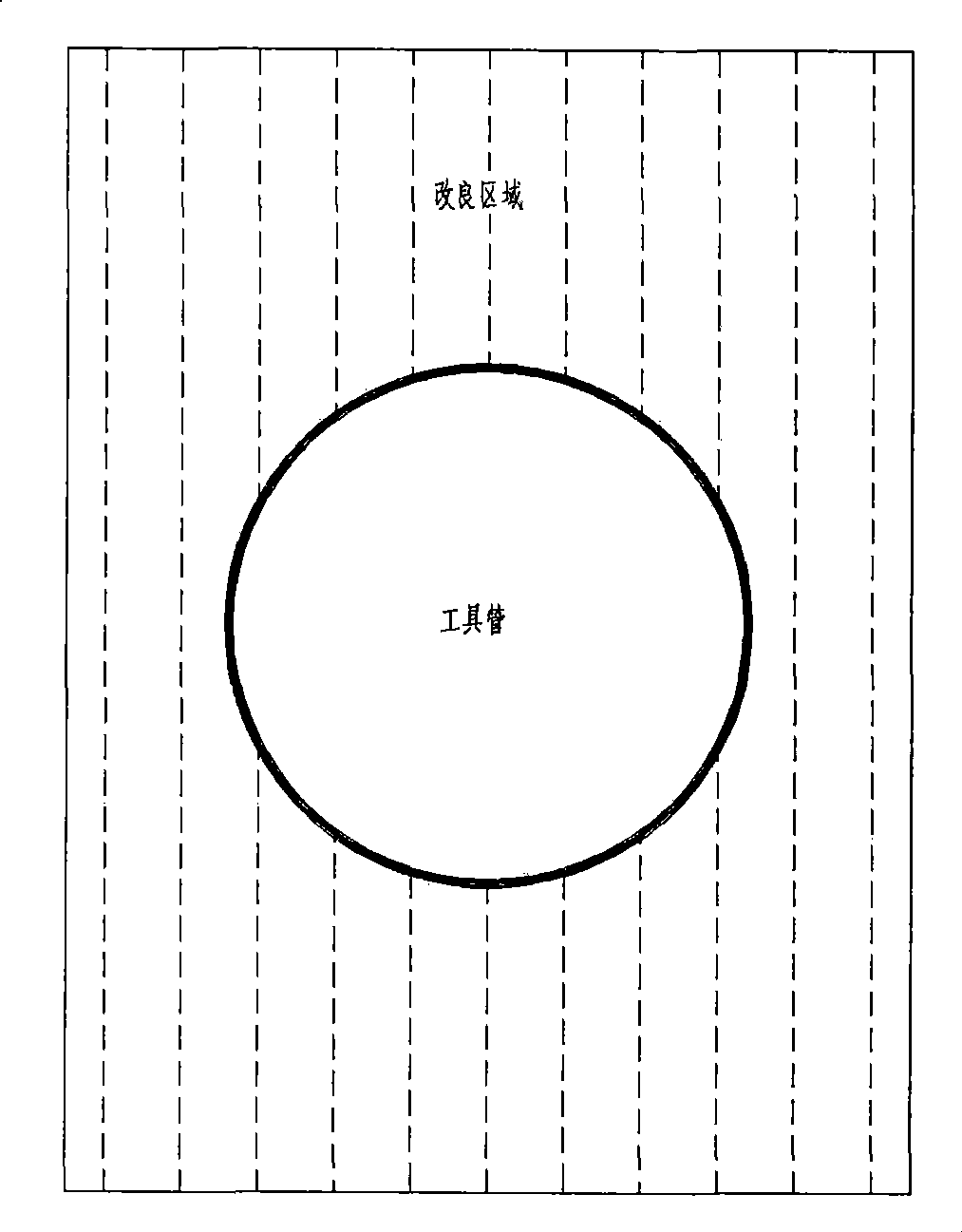

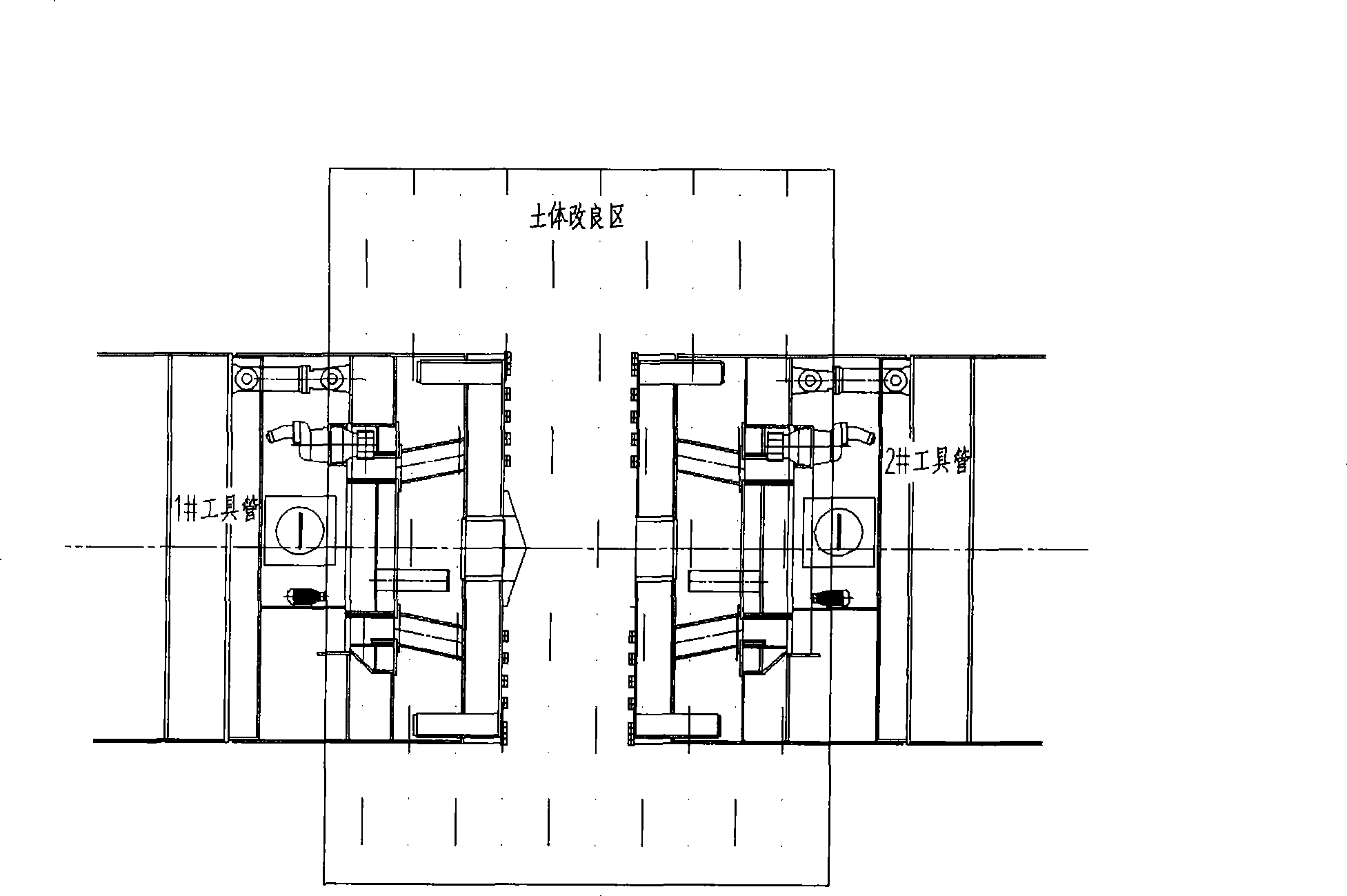

[0038] 1. Soil improvement in docking area ( figure 1 ,2)

[0039] In order to ensure the smooth docking of pipe jacking, the position of the two pipe jacking tool pipes should be limited to prevent unnecessary lateral displacement of the tool pipes duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com