High-efficiency external evaporation heat exchanger with perturbation and safe oil return

An evaporative heat exchanger and high-efficiency tube technology, which is used in evaporators/condensers, lighting and heating equipment, refrigeration and liquefaction, etc. Accidents and other problems, to achieve the effect of easy bubbles to rise rapidly, avoid entrainment of droplets, and prevent liquid shock accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

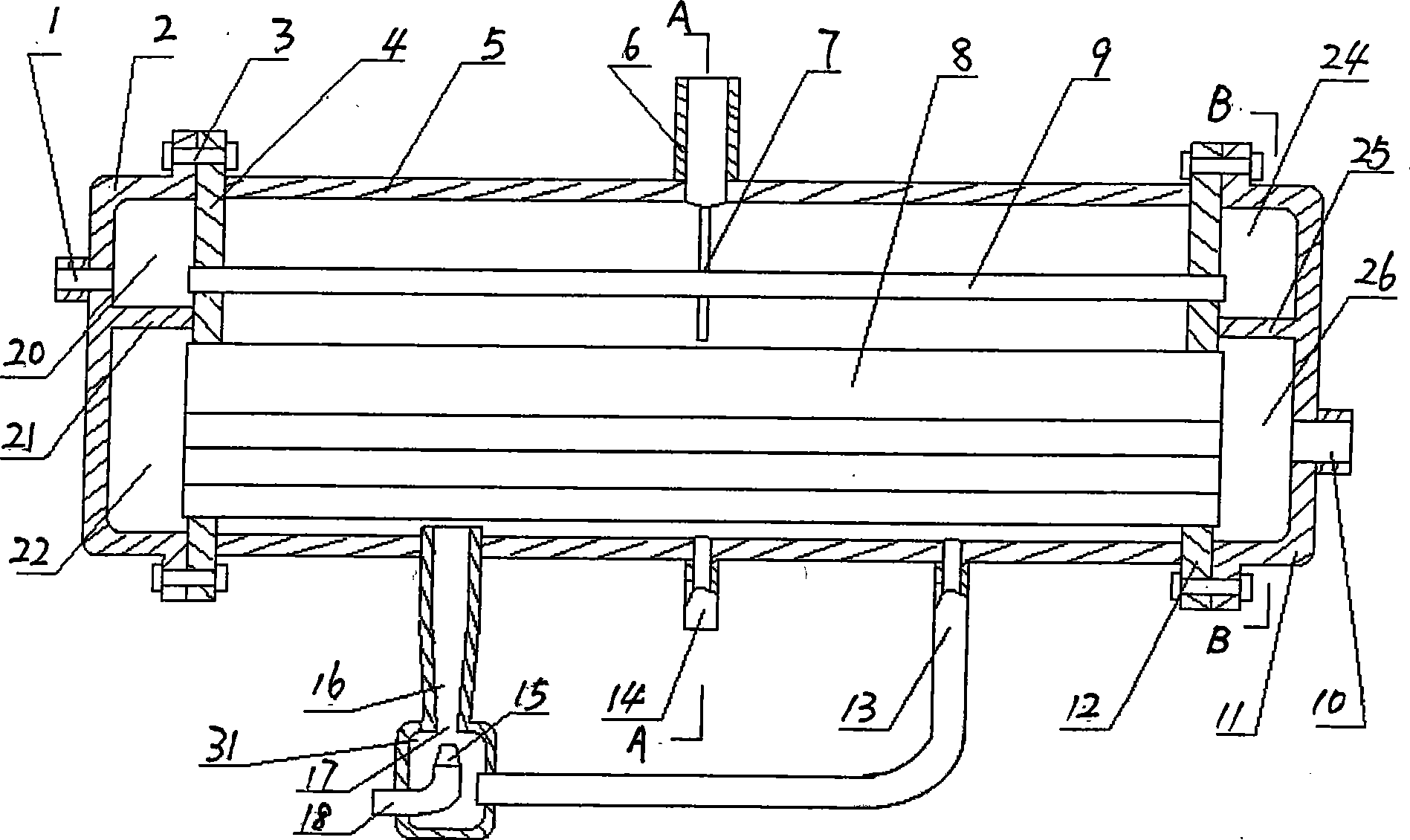

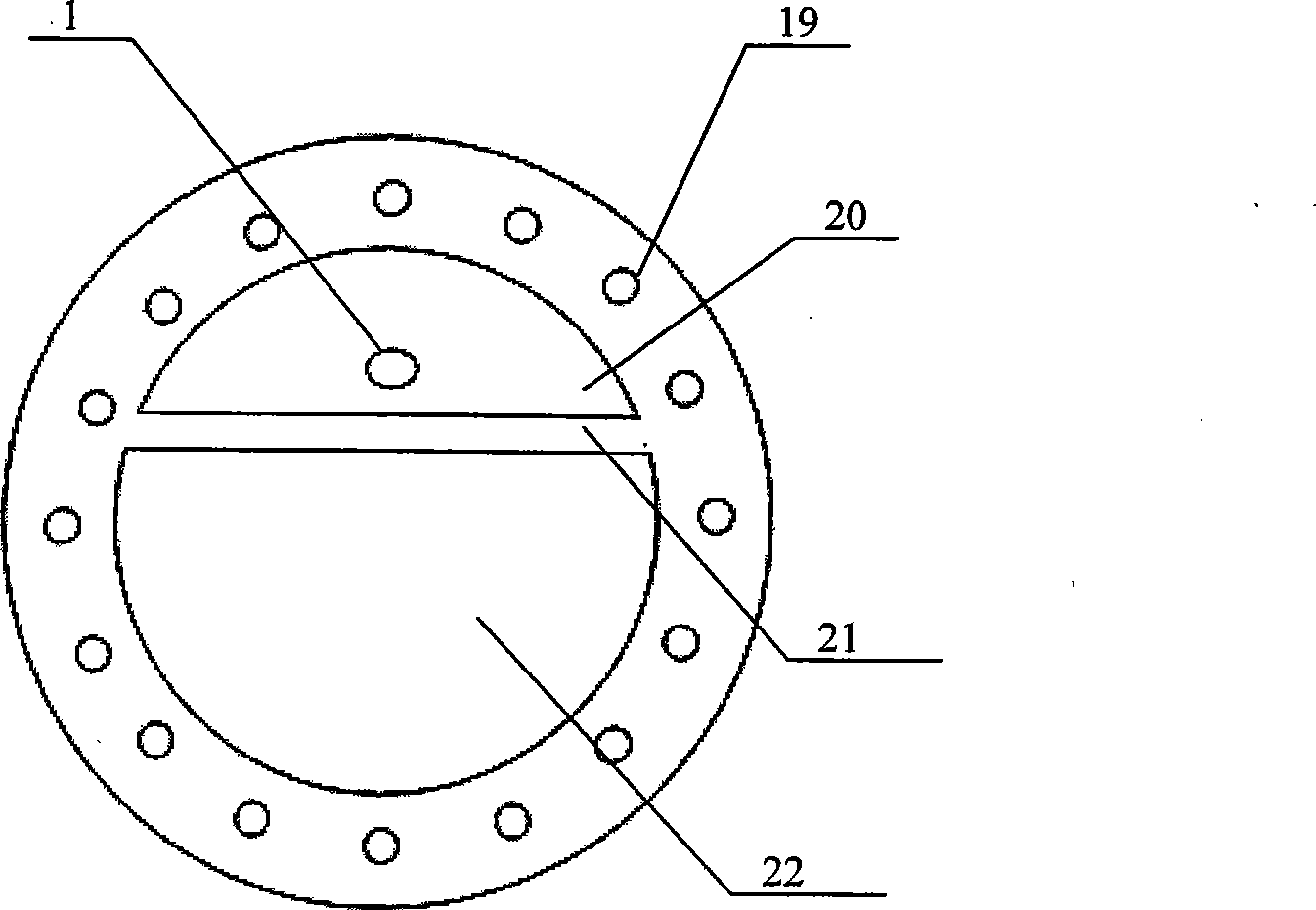

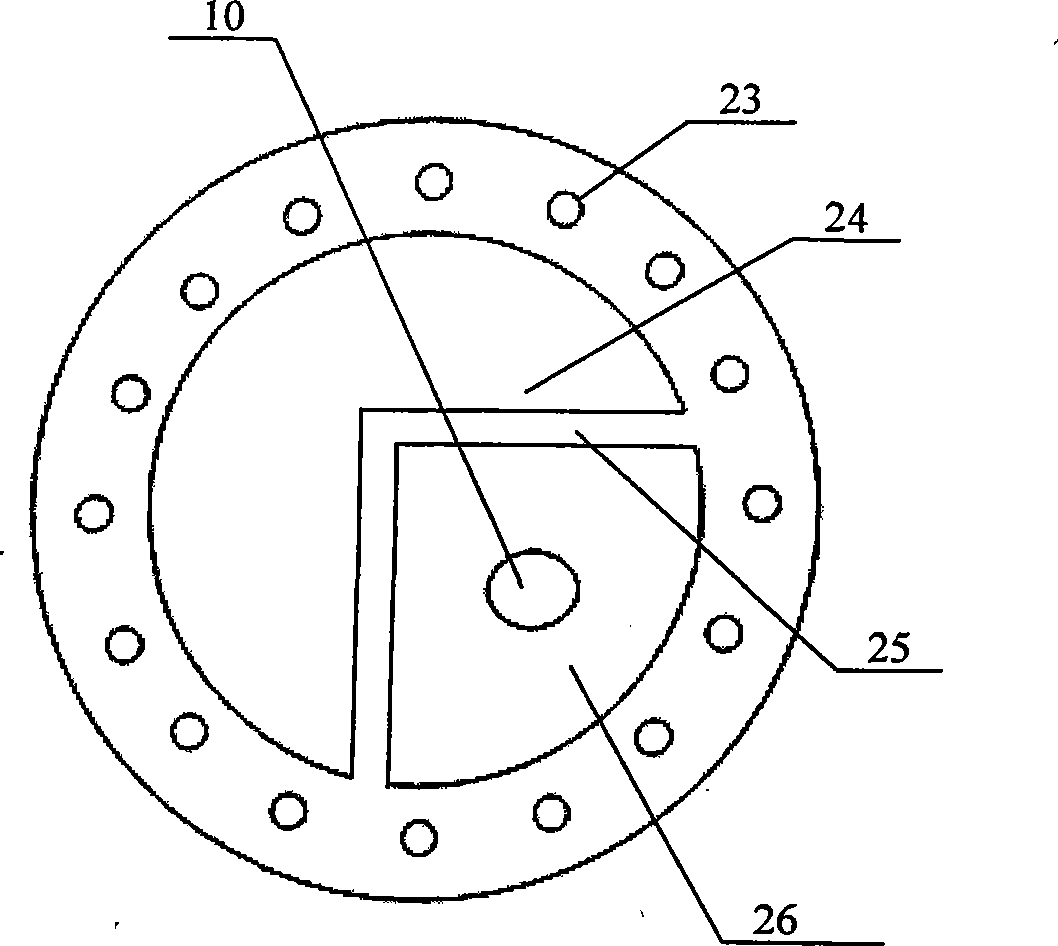

[0029] figure 1 It is a schematic diagram of a high-efficiency external tube evaporation heat exchanger with disturbance and safe oil return in the present invention, including a cylindrical shell 5, a first head 2, a first tube sheet 4, a second head 11, a second Tube sheet 12, multiple vertical heat exchange flat tubes 8 and horizontal heat exchange flat tubes 9 placed side by side. Both the vertical heat exchange flat tubes 8 and the horizontal heat exchange flat tubes 9 are extruded from aluminum, and a plurality of tiny internal passages are formed inside the vertical heat exchange flat tubes 8 and the horizontal heat exchange flat tubes 9 . Both ends of the casing 5 are welded to the first tube sheet 4 and the second tube sheet 12 respectively. The schematic diagram of the first tube sheet is shown in Figure 4 As shown, connecting bolt holes 27, horizontal heat exchange flat tube holes 28 and a plurality of vertical heat exchange flat tube holes 29 are respectively pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com