Cooking range tossing flame guide structure and flame guide device

A stove and pot-turning technology, which is applied in the field of stove pot-turning flame-guiding structure and flame-guiding device, to achieve the effect of overcoming pressure adaptation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

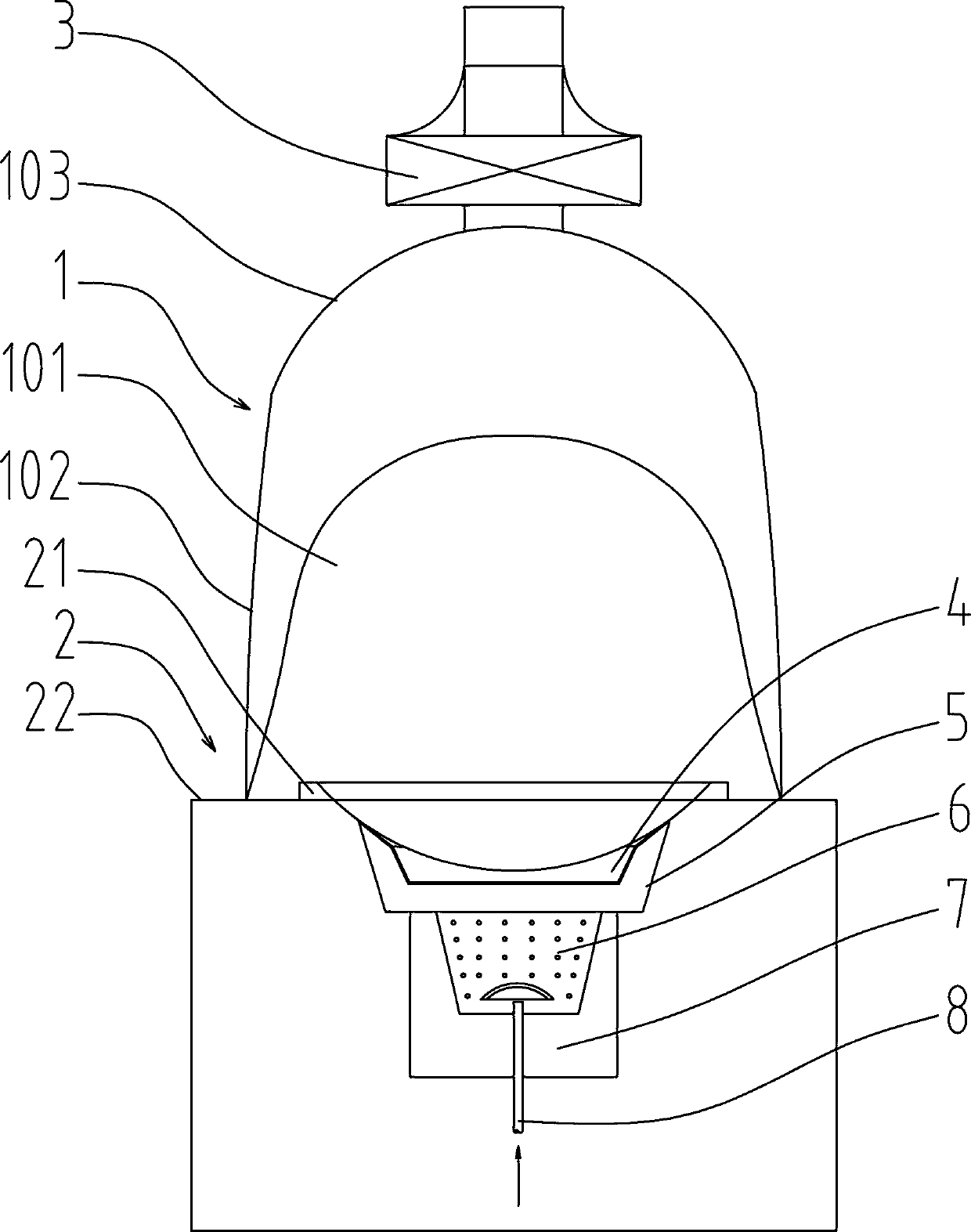

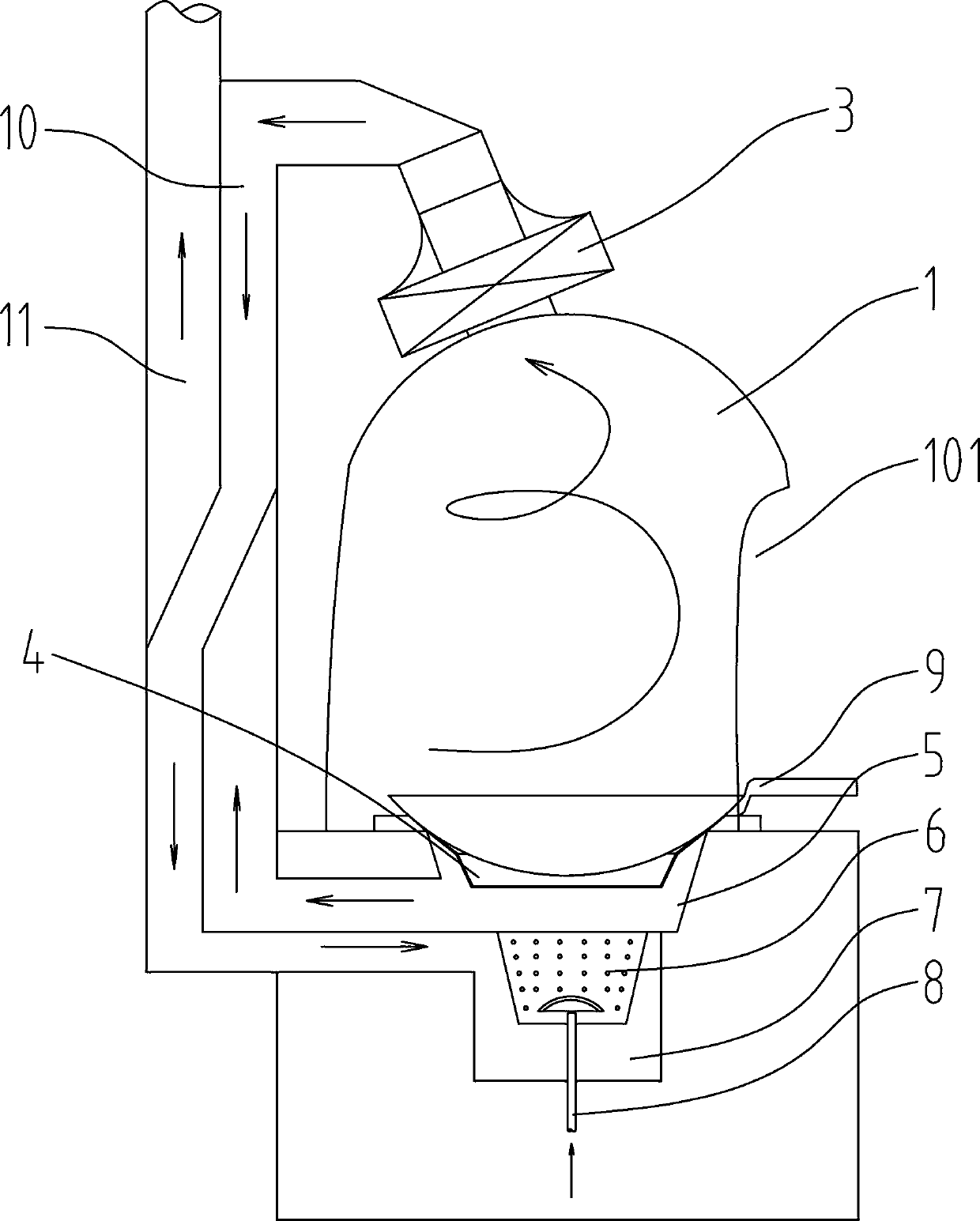

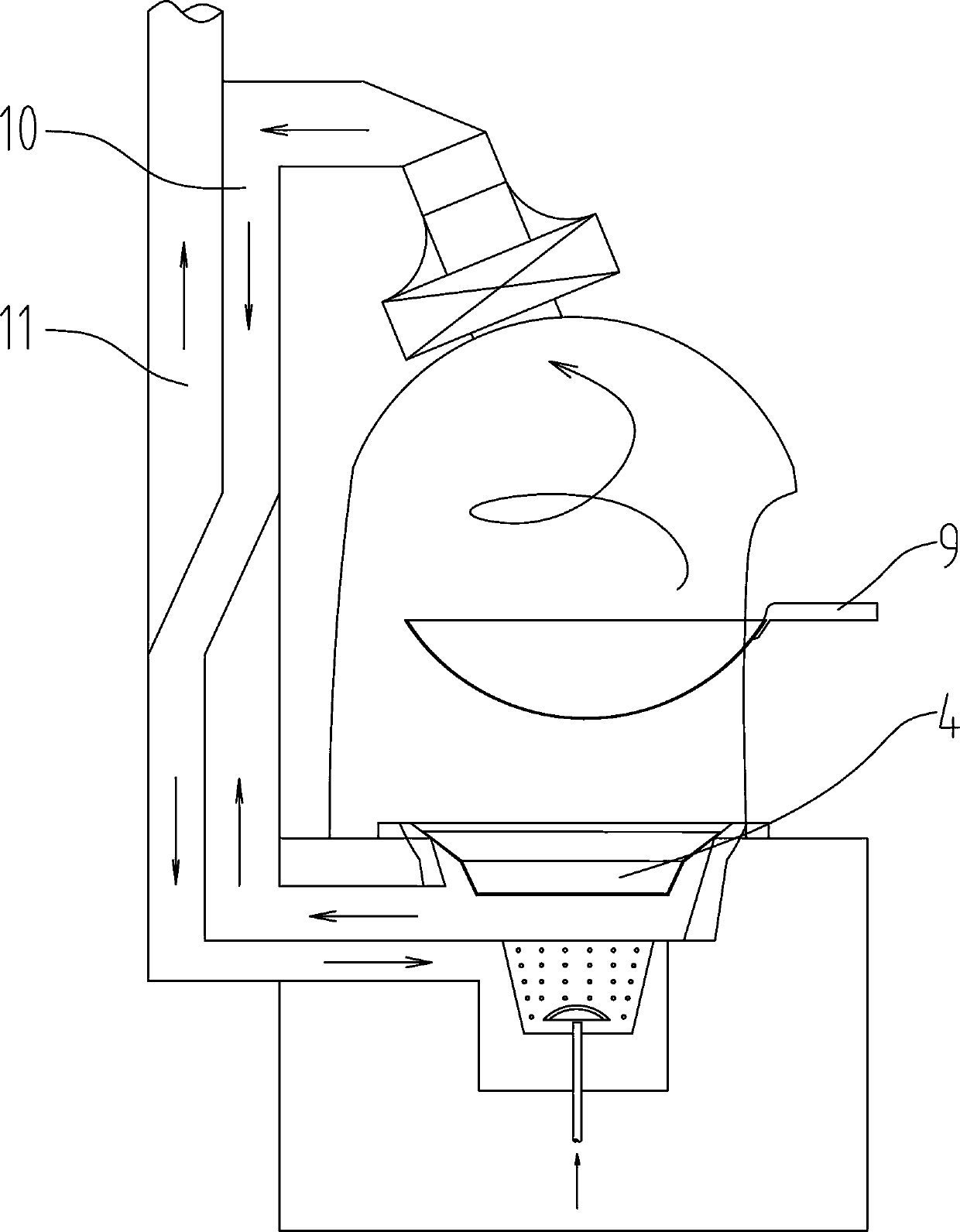

[0042] Such as Figure 1~7 Among them, a stove topping pot flame guide device, including a stove body 2, a furnace is provided in the stove body 2, a flame guide device 4 is provided between the upper part of the furnace hearth and the pot 9, and the space between the furnace hearth and the flame guide device 4 In communication with the chimney, a recessed portion 42 is provided on the flame guiding device 4 , and a cavity structure is formed between the recessed portion 42 and the bottom of the pot 9 . Preferably, a fire hole 43 or a fire grill 45 is provided in the recessed portion 42 . With this structure, the cavity structure between the recessed portion 42 and the bottom of the pot 9 maintains a positive pressure all the time, and the flame can be prevented from erupting toward the operator, thereby overcoming the influence of the pot upset on the operator. It should be noted that in the prior art, there is also a scheme of controlling the gas output to make the flame sm...

Embodiment 2

[0052] In a preferred solution, a smoke hood 1 that limits the section of the air inlet is provided above the cooker body 2, a smoke hood side wall 102 and the back side are provided with a smoke hood side wall 102, a smoke hood dome 103 is provided on the top, and a smoke hood dome 103 is provided on the front. An air inlet 101 is provided, and the cross section of the air inlet 101 is set such that when the exhaust fan 3 is activated, the inner cavity of the fume hood 1 is under negative pressure compared with the atmospheric environment. That is, when the exhaust fan 3 is started, the oxygen supply air enters the fume hood 1 from the air inlet 101 in the atmospheric environment under the negative pressure condition. With this structure, the efficiency of oil fume collection is greatly improved.

[0053] In a preferred solution, the distance between the side wall 102 of the fume hood and the stove body 2 is 0-30 cm. Specifically, the distance between the bottom of the arc-s...

Embodiment 3

[0060] In a preferred scheme, the position near the top of the fume hood dome 103 is connected to the air inlet of the exhaust fan 3, and the air outlet of the exhaust fan 3 is connected to the oil fume passage 10, and the oil fume passage 10 is connected to the air inlet chamber 7 in the furnace, and the air inlet chamber 7 communicates with the mixing chamber 6 through the porous net, the gas pipe 8 communicates with the mixing chamber 6, the upper part of the mixing chamber 6 is provided with a combustion chamber 5, the combustion chamber 5 is connected with the fire channel 11, the fire channel 11 is connected with the chimney, and the combustion chamber 5 is located Below the flame guide device 4; with this structure, the collected oil fume passes through the oil fume passage 10 from the air inlet chamber 7, passes through the porous mesh, and enters the combustion chamber 5 after the mixing chamber 6 is fully mixed with the gas from the gas pipe 8 Combustion, the high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com