Siphon type gas-liquid separation and oil return apparatus in parallel compression refrigeration units

A technology of compression refrigeration and gas-liquid separation, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of complex structural design of the overall unit, affect the structural design of the overall unit, reduce the amount of liquid absorption, etc., and achieve improved system operation Efficiency and compressor reliability, simple and reasonable structure, and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with embodiment.

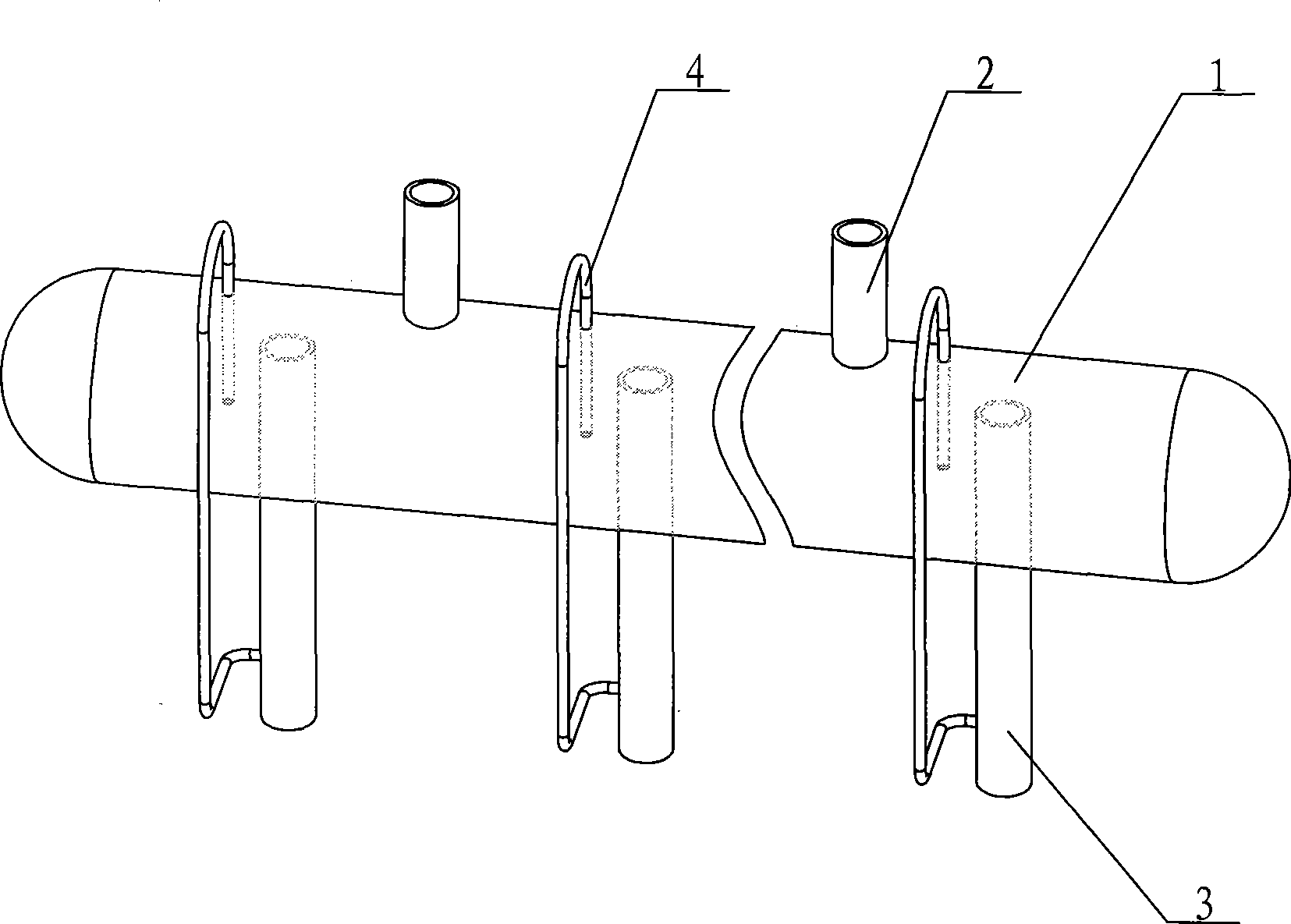

[0010] figure 1 A siphon type gas-liquid separation and oil return device in a parallel compression refrigeration unit, the evaporator return pipe 2 is installed on the top of the suction header 1, and the suction port section of the compressor suction branch pipe 3 passes through the suction header The bottom of 1 is inserted into the middle or above the middle of the suction manifold 1, one end of the siphon oil return pipe 4 is connected to the air outlet section of the compressor suction branch 3, and the other end is inserted from the top of the suction manifold 1 to the suction manifold 1 At or below the middle of the tube.

[0011] The entire parallel compression refrigeration unit mainly includes four major components: compressor, condenser, evaporator and expansion valve, among which the suction header has a special structure. The refrigerant gas is compressed by the compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com