Method for testing automobile hub bearing unit torque rigidity

A technology of automobile wheel hub and testing method, which is applied in the direction of measuring device, torque measurement, power measurement, etc., can solve the problems of simple test conditions, large error of test data, low test simulation, etc., and achieve good repeatability, stable loading, The effect of reducing tedious calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

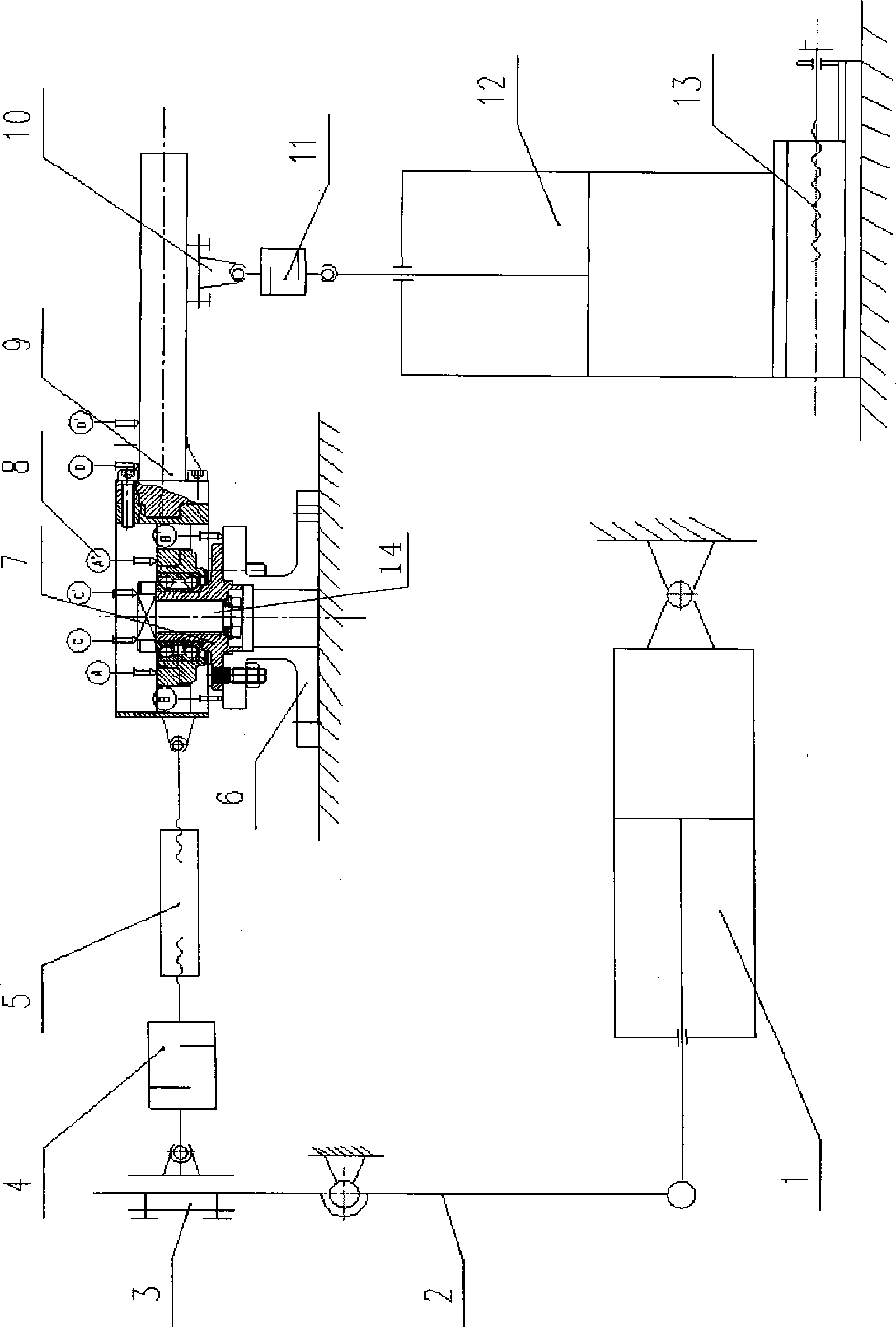

[0025] The test method of the moment rigidity of the automobile hub bearing unit of the present invention comprises figure 1 In the shown test device, a differential transformer type displacement sensor (8) is configured on the test device, and the tested data is fed back to the computer for analysis and comparison, and the moment rigidity value is calculated, wherein

[0026] ① The test device includes an axial loading cylinder, an axial loading adjustment part, a radial loading cylinder, a radial loading adjustment part, a test base, a combined loading sleeve and a mandrel;

[0027] ② There are eight differential transformer displacement sensors (8) distributed on the test point;

[0028] ③ The computer contains analysis software;

[0029] The inner ring flange of the tested automobile hub bearing unit (7) is fixedly installed on the test base (6) by bolts, and the test mandrel (14) is set on the inner ring, and the combined loading sleeve (9) is fixedly installed on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com