Composite material and preparation method thereof, electrode material containing the composite material and capacitor

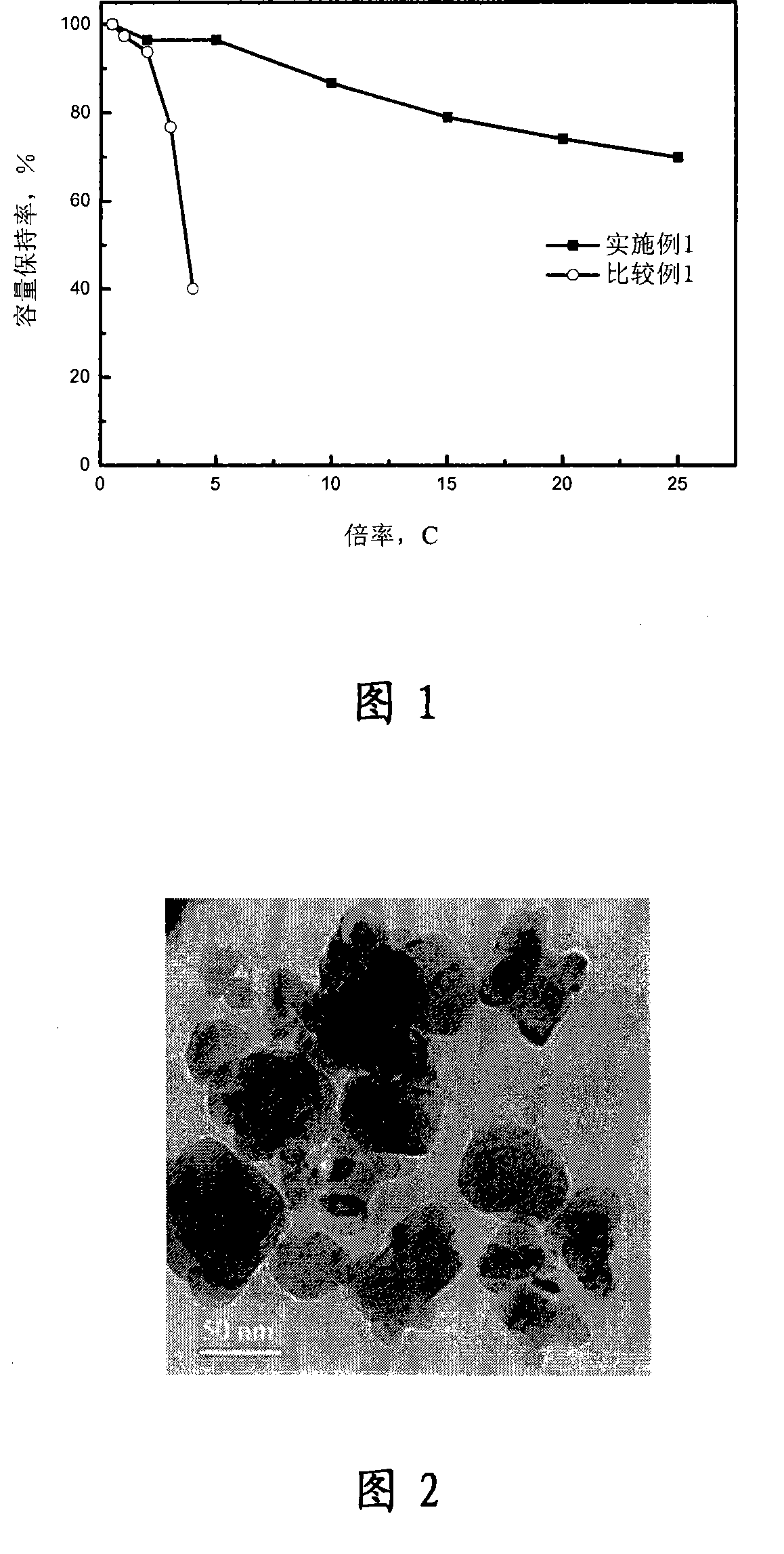

A composite material and bulk material technology, applied in the field of lithium-titanium-oxygen composite materials, can solve the problems such as the inability to meet the requirements of high-rate charge and discharge of capacitors, the reduction of electrode conductivity, and the inability to improve electrode density, and achieve excellent practical use value, such as Energy, the effect of highlighting high-rate discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In another aspect of the present invention, the present invention relates to the preparation method of above-mentioned composite material, it comprises the steps:

[0031] - coating step, wherein the raw material nano-titanium dioxide is coated with carbon at a temperature of 700-1000° C. to obtain a titanium dioxide material partially or completely coated with carbon, and

[0032] - A calcination step, wherein the coated material is calcined with a stoichiometric ratio of lithium compound at 700-900° C. for 3-24 hours.

[0033] When preparing the carbon-coated titanium dioxide precursor according to the method of the present invention, the carbon material and the titanium dioxide material are not simply mixed, but are formed through the interaction between the carbon source and the raw material titanium dioxide at high temperature. Specifically, in the present invention, carbon is closely combined on the surface of the titanium dioxide material through gas phase, liqui...

Embodiment 1

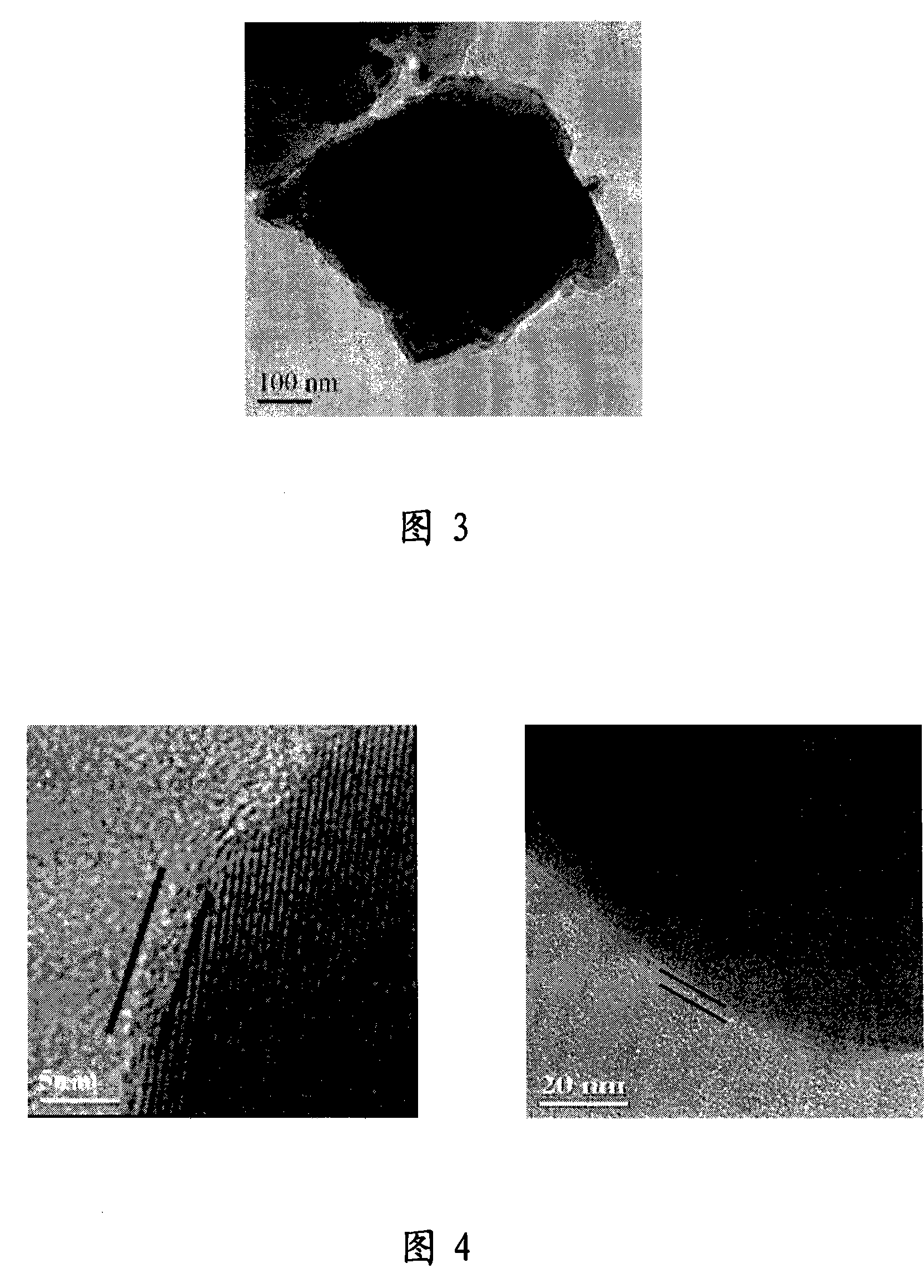

[0043] TiO with a particle size of 8nm 2 The material is a raw material, which is placed in a tube furnace. Toluene is used as the carbon source, Ar gas is used as the gas source, the Ar gas flow rate is controlled to 1L / min, and the toluene vapor is blown into the tube furnace. Temperature, control furnace temperature at cladding temperature for 300 minutes. After cooling, it is mixed with LiOH according to the stoichiometric ratio, ground, and calcined at 800°C for 12 hours to obtain carbon-coated lithium titanyl oxide (Li 4 Ti 5 o 12 ) composite material, the carbon coating amount of this material is 5% by weight. 2 is a transmission electron micrograph of the composite material obtained in Example 1. It can be seen from the transmission electron micrograph in Fig. 2 that the particle size of the composite material obtained in Example 1 is in the range of 20-50 nm.

[0044] Material testing (half-cell) electrode preparation: mix the slurry according to the ratio of li...

Embodiment 2

[0052] The carbon-coated lithium-titanium-oxygen composite material prepared by the method in Example 1 was assembled with commercially available activated carbon to form an asymmetric supercapacitor. The negative electrode composition of the capacitor is mixed according to the ratio (weight ratio) of lithium titanium oxide composite material: conductive graphite: carbon black: binder = 65:16:9:10 (weight ratio), and then the coating thickness is controlled to be 80 μm, and both sides are evenly coated on the copper foil current collector. After the electrode is dry, at 1 ton / cm 2 Initially press the electrode sheet, and then press 2ton / cm 2 Press to a certain thickness. The thickness of the obtained pole piece is about 55μm, and the coating amount is 3mg / cm 2. Cut the pole piece to the specification of 250mm×30mm, and weld the tab at 65mm of the electrode piece (the width of the welding position is 6.5mm). The activated carbon used as the positive electrode material is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com