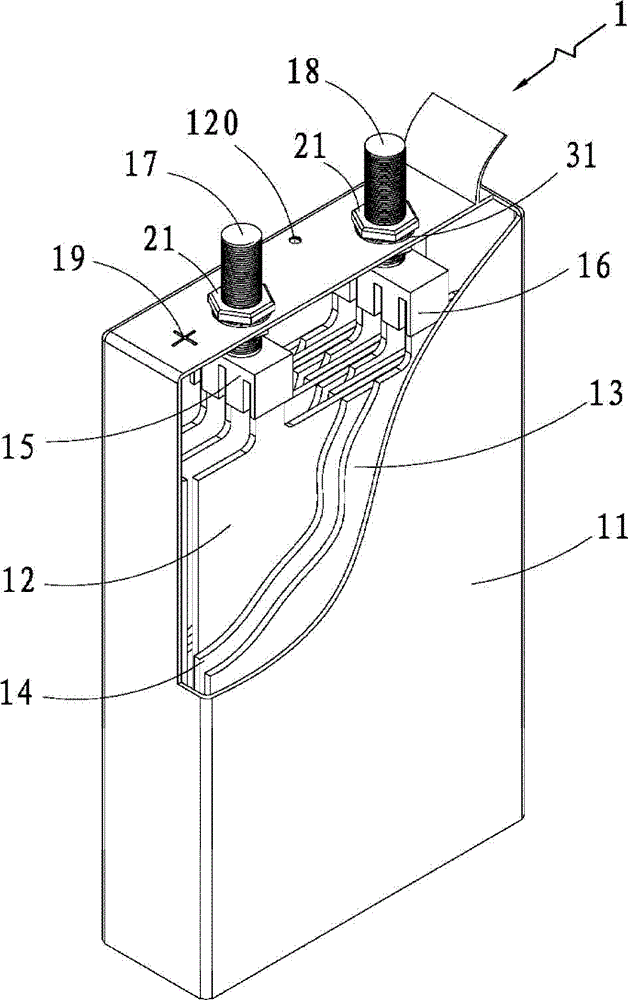

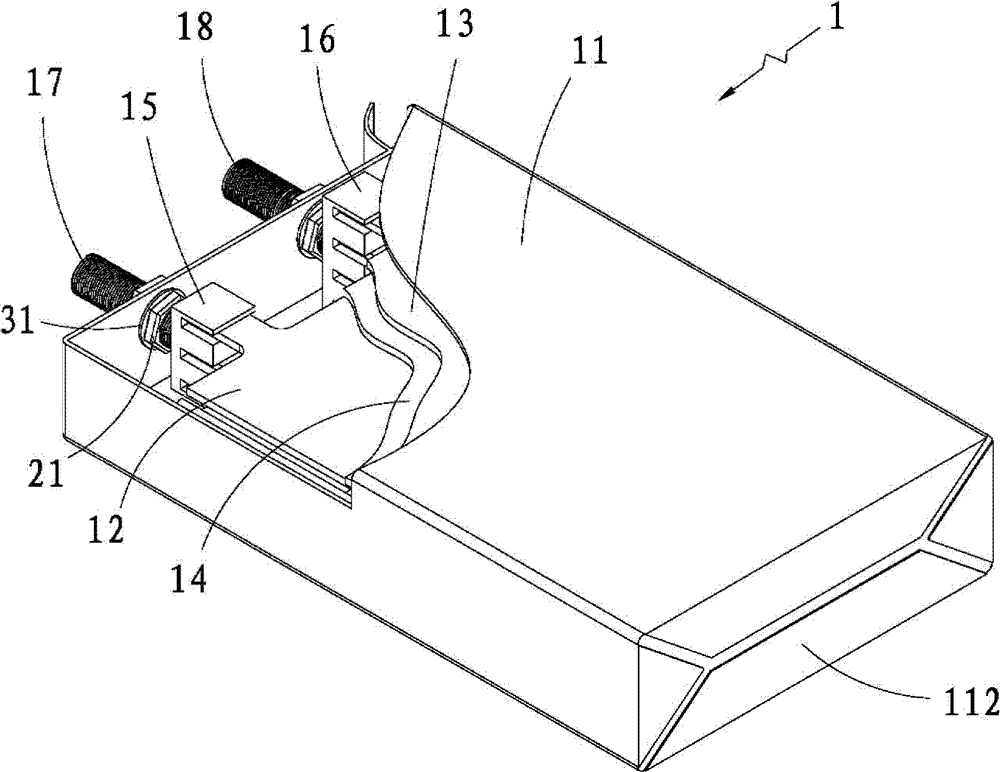

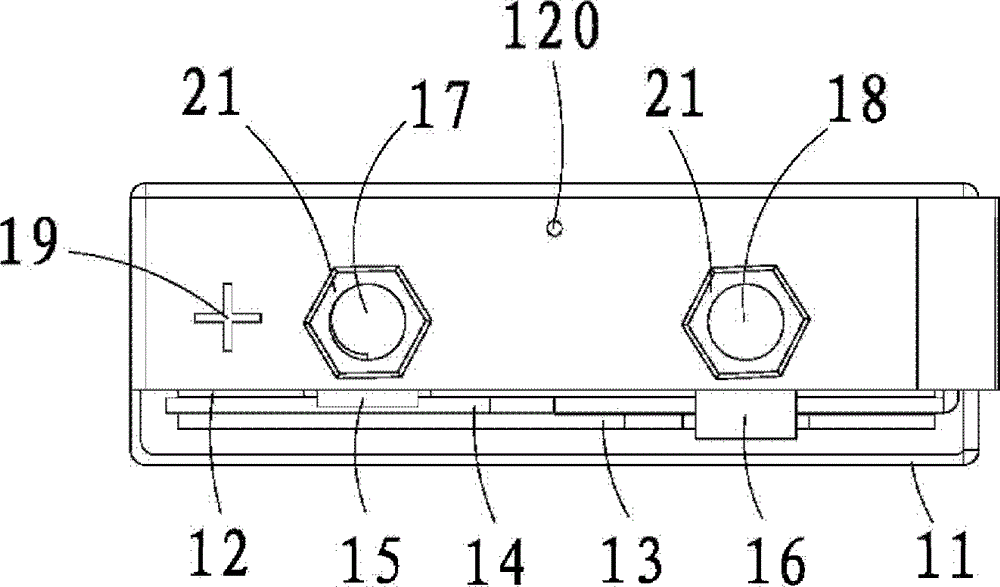

Thin shell lead-acid battery and its manufacturing method

A lead-acid battery, single battery technology, applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc., to achieve the effect of good shape design plasticity, good sealing, and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0058] Furthermore, as a preferred implementation of the thin case lead-acid battery provided by the present invention, in this embodiment, 2V is used as the design specification of a finished unit.

[0059] Further, see Figure 8, as a specific embodiment of the thin-case lead-acid battery provided by the present invention, the thin-case lead-acid battery is formed by connecting at least two single cells 1 in groups, and one of the single cells 1 They are connected in series, or in parallel, or combined in series and parallel. In this embodiment, the design voltage of the single battery 1 is 2V, so it can be matched according to the capacity and internal resistance of the 2V battery, and connected into combined batteries with different output voltages or currents to meet different conditions. For example, battery packs with even voltages such as 4V, 6V, 8V, and 12V can be matched to further improve the consistency of the battery pack and prolong the service life of the batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com