Copper phosphate plus plate material for lithium battery and its preparation method

A cathode material, copper phosphate technology, used in electrode manufacturing, battery electrodes, phosphates, etc., can solve problems such as potential safety hazards, and achieve the effects of easy operation, solving voltage hysteresis, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

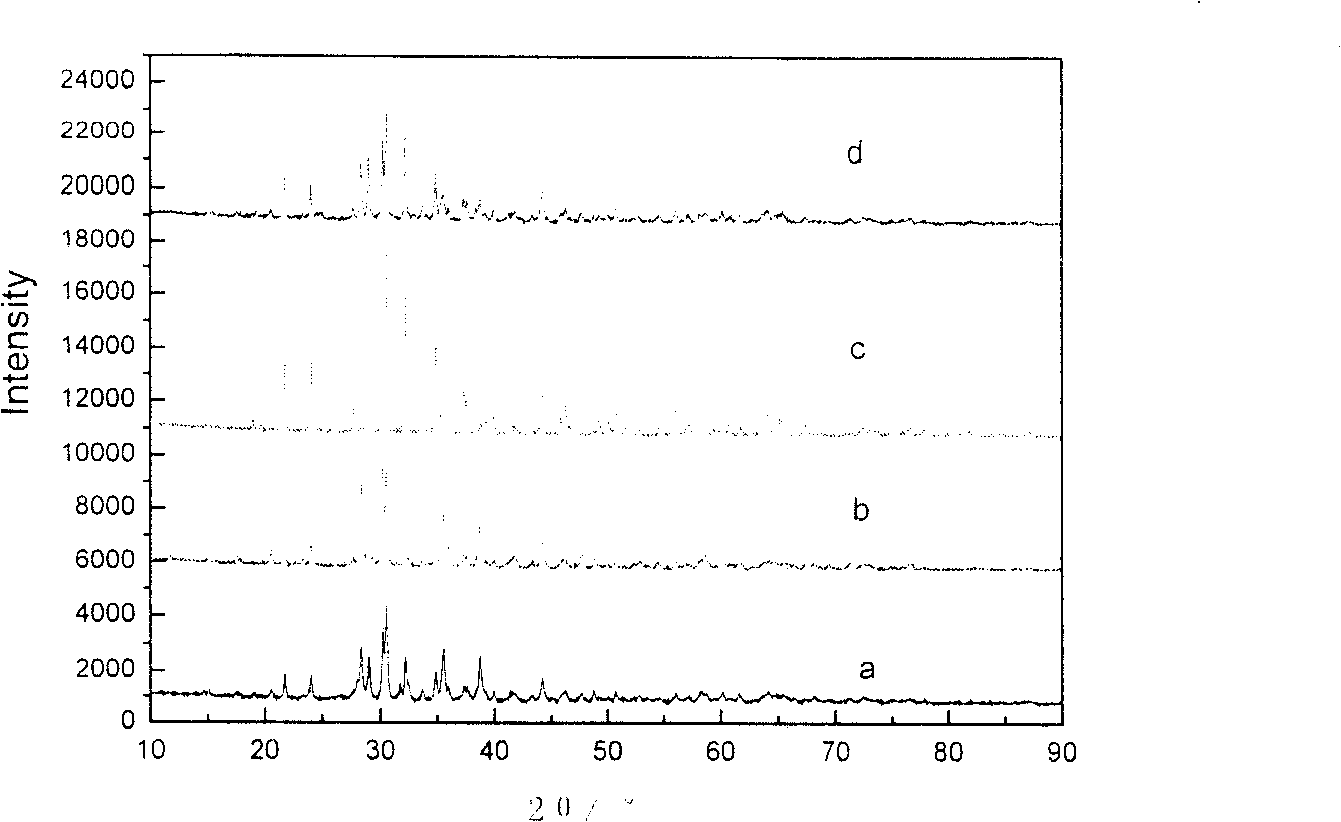

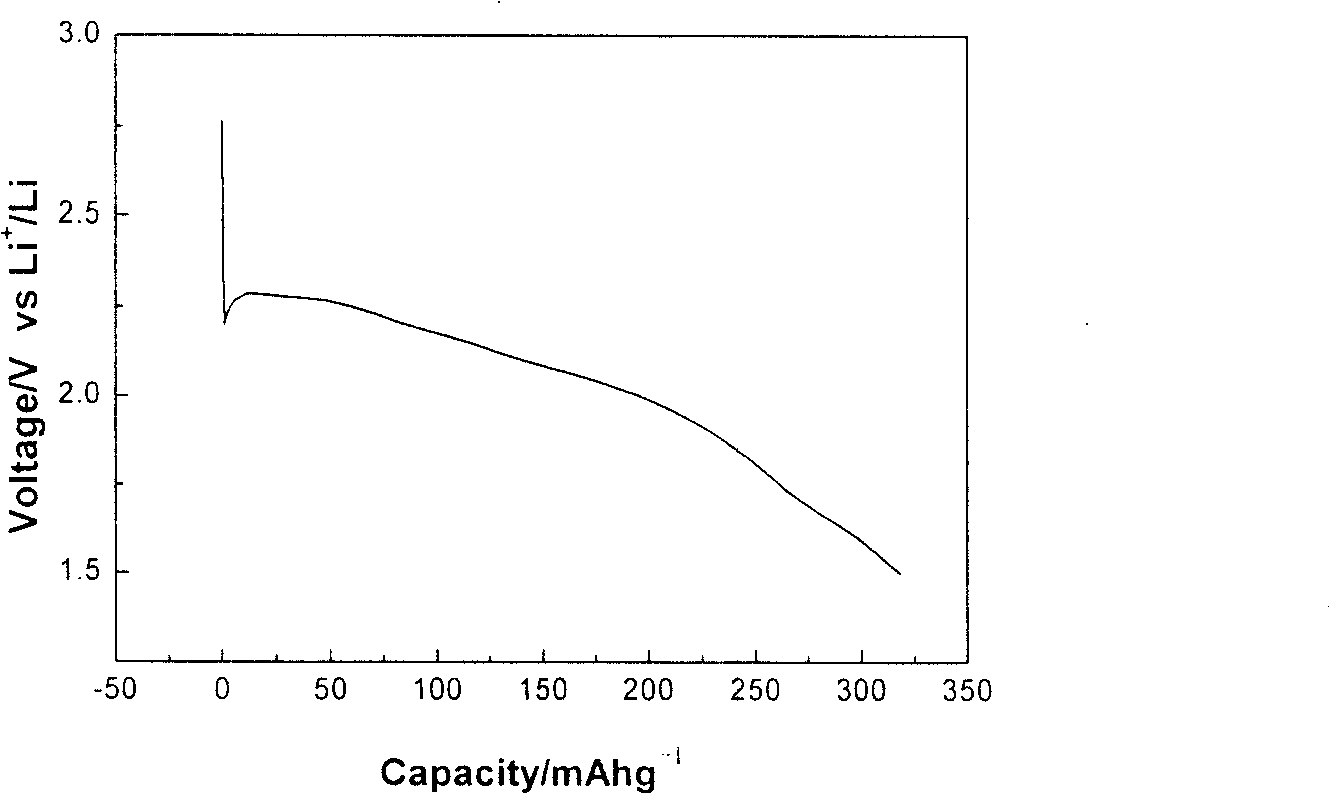

Embodiment 1

[0023] 1.19g CuO and 1.15g NH 4 h 2 PO 4 In an agate ball mill jar, use 10ml of acetone as a dispersant, and ball mill for 5 hours (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat in a box-type resistance furnace, heat-treated at 700° C. for 10 h in an air atmosphere, and naturally cooled to room temperature to obtain the copper phosphate material. According to the mass ratio of copper phosphate material: acetylene black: binder = 80:10:10, after ball milling and mixing, apply it on the treated aluminum foil, dry it at 120°C, and press it at 20MPa to obtain the positive electrode for lithium battery.

Embodiment 2

[0025] 5.96g CuO and 5.75g NH 4 h 2 PO 4In an agate ball mill jar, use 30ml acetone as a dispersant, and ball mill for 3 hours (rotation speed 600r / min). After the acetone is volatilized, it is transferred to a porcelain boat in a box-type resistance furnace, heat-treated at 800° C. for 10 h in an air atmosphere, and cooled naturally to room temperature to obtain the copper phosphate material. According to the mass ratio of copper phosphate material: acetylene black: binder = 80:10:10, after ball milling and mixing, apply it on the treated aluminum foil, dry it at 120°C, and press it at 20MPa to obtain the positive electrode for lithium battery.

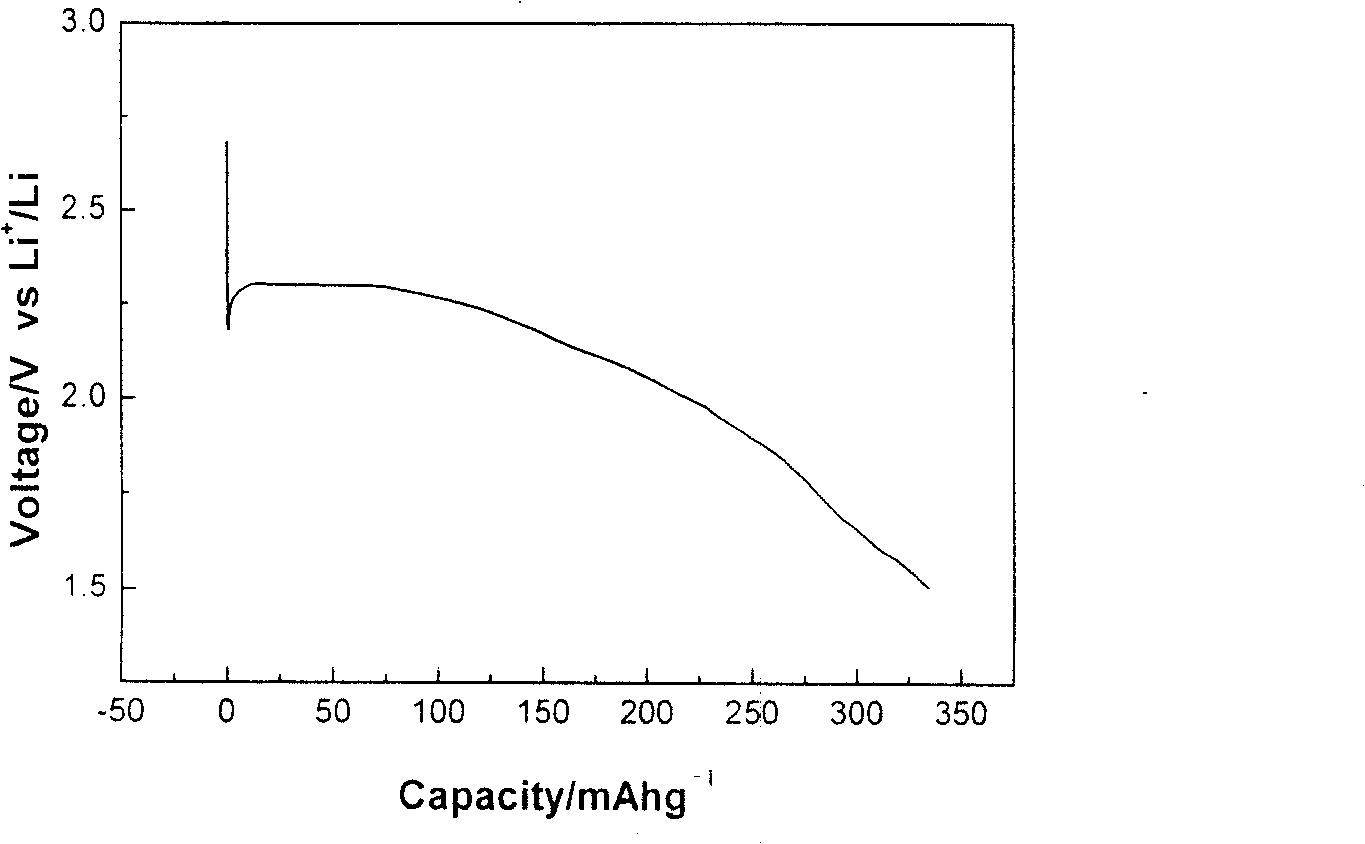

Embodiment 3

[0027] 11.93g CuO and 11.5g NH 4 h 2 PO 4 In an agate ball mill jar, use 40ml acetone as a dispersant, and ball mill for 10 hours (rotation speed 500r / min). After the acetone is volatilized, it is transferred to a porcelain boat in a box-type resistance furnace, heat-treated at 900°C for 3 hours in an air atmosphere, and cooled naturally to room temperature to obtain the copper phosphate material. According to the mass ratio of copper phosphate material: acetylene black: binder = 80:10:10, after ball milling and mixing, apply it on the treated aluminum foil, dry it at 120°C, and press it at 20MPa to obtain the positive electrode for lithium battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com