Nondestructive sheet material bending mould

A technology for bending molds and plates, which is applied in the field of mechanical processing, and can solve problems such as difficult guarantees, unevenness, and coarse tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Bottle holder processing

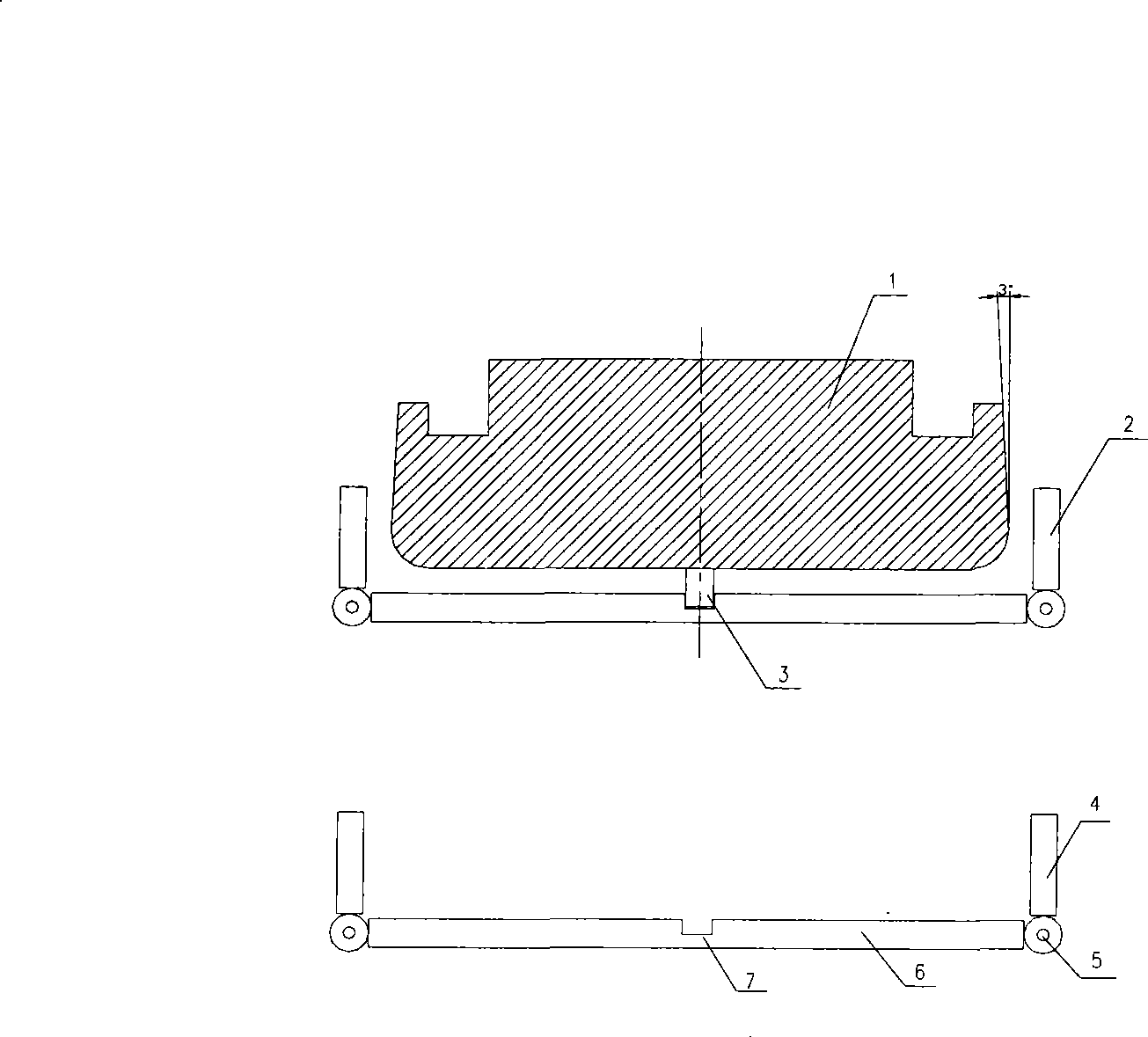

[0017] 1. The material of the bracket is LF12, the thickness is 5mm, the bending angle is 90°, and the area is 400×200mm 2 , place the plate. Place the plate to be processed on the lower die 2. Note that the grain direction of the material should be vertical to the bending line.

[0018] 2. Align the upper mold 1 to press the plate, and then fix the upper mold 1, the plate and the lower mold 2 with the pin 3, so as to prevent the plate to be processed from moving.

[0019] 3. Use a special jack to act on the outside of the two bending plates 4 to control the moving speed, requiring a uniform and slow speed until the plate reaches the two ends of the upper mold 1. Since the two ends of the upper mold 1 are set at 87°, Use 3° as the bending rebound to ensure that the bend is in place at 90° at one time, avoiding back-and-forth correction.

[0020] 4. The shape of the finished bracket is U-shaped, and the bottom end is perpendicular to the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com