Production method for welded cylinder block of marine diesel engine

A technology for marine diesel engines and manufacturing methods, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of increasing the difficulty of component manufacturing and assembly, large welding stress, and difficult welding process, etc., to reduce production and processing costs, The effect of reducing assembly errors and saving the amount of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

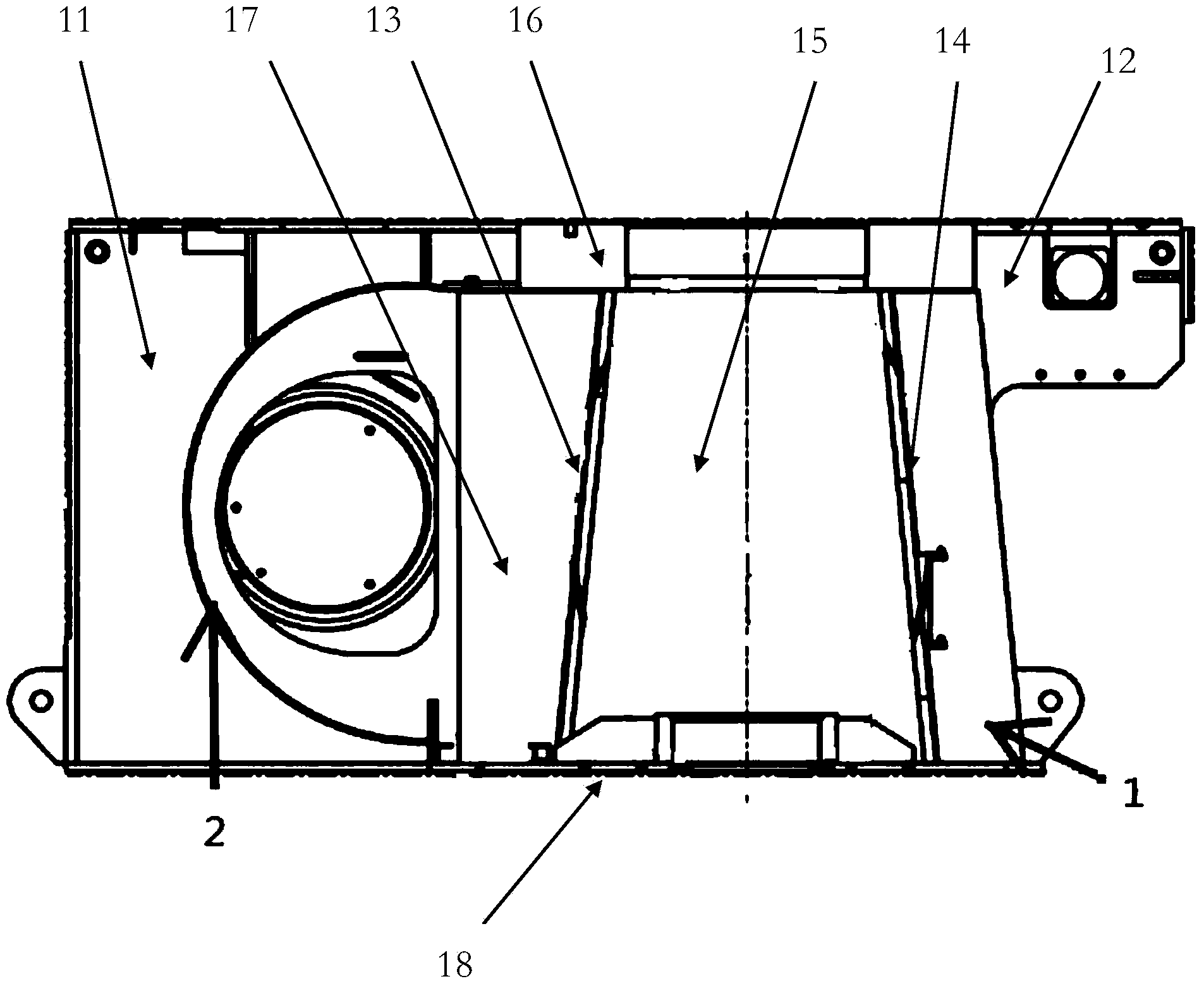

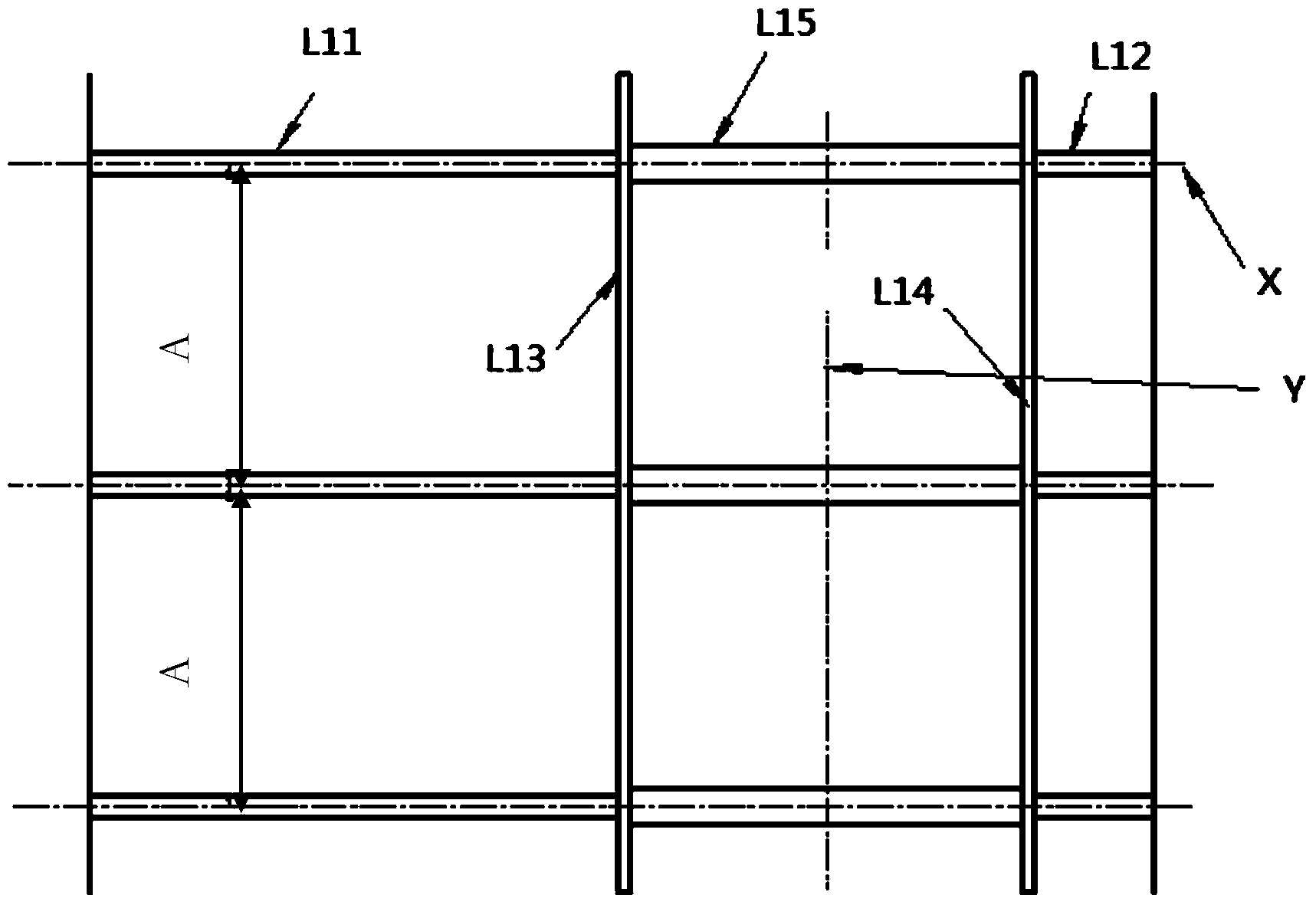

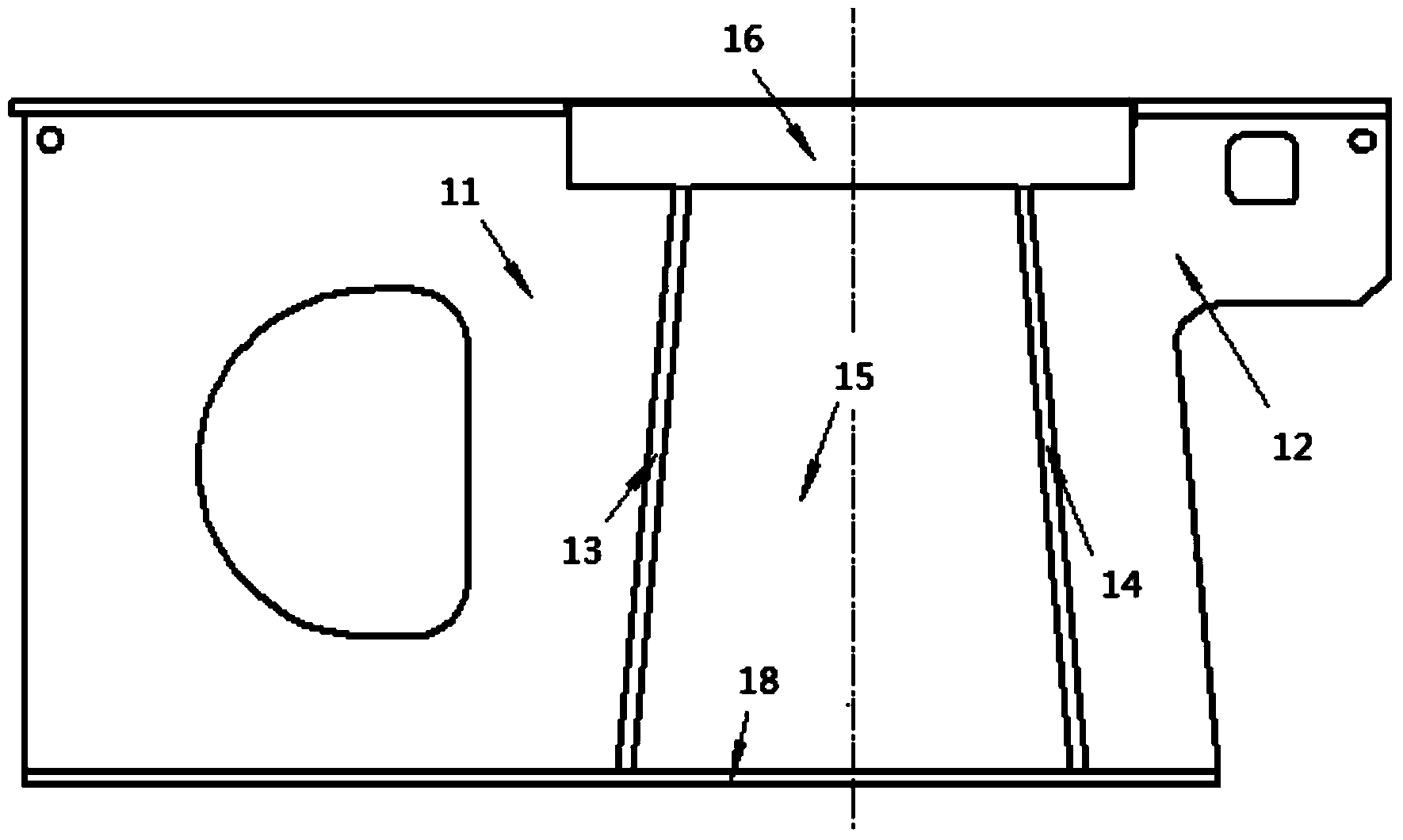

[0041] The invention provides a manufacturing method for manufacturing welded cylinder blocks of marine diesel engines, please refer to figure 1 , the welded cylinder block includes a cylinder block box 1 and a scavenging device 2 . The cylinder body box 1 includes a bottom plate 18, a plurality of first transverse webs 11, a plurality of second transverse webs 12, a plurality of intermediate partitions 15, a first side plate 13, a second side plate 14, and a plurality of triangular tubes plate 17 and panel 16; said bottom plate 18 is arranged horizontally at the bottom; see Figure 4 , the plurality of first transverse webs 11, the plurality of second transverse webs 12 and the plurality of intermediate partitions 15 are arranged in the transverse direction and are w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com