Mining method for segmented metallic ore

A mining method and technology for metal ore, applied in surface mining, mining equipment, earth-moving drilling, etc., can solve problems such as adverse environmental impact, high labor intensity, land occupation, etc., to reduce adverse effects, improve mining efficiency, and reduce resources. the wasteful effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with manganese ore mining by accompanying drawing.

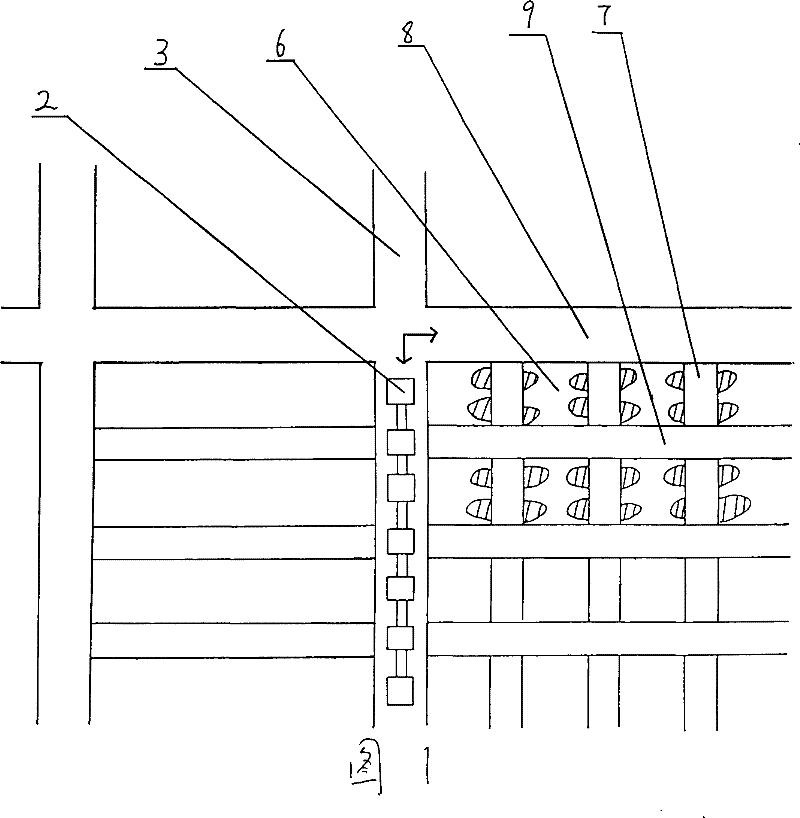

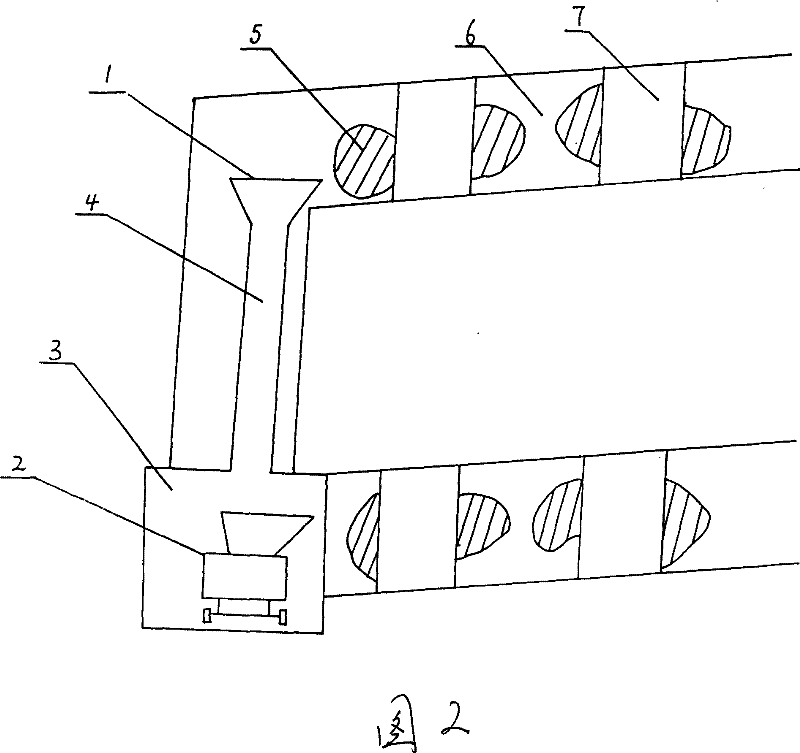

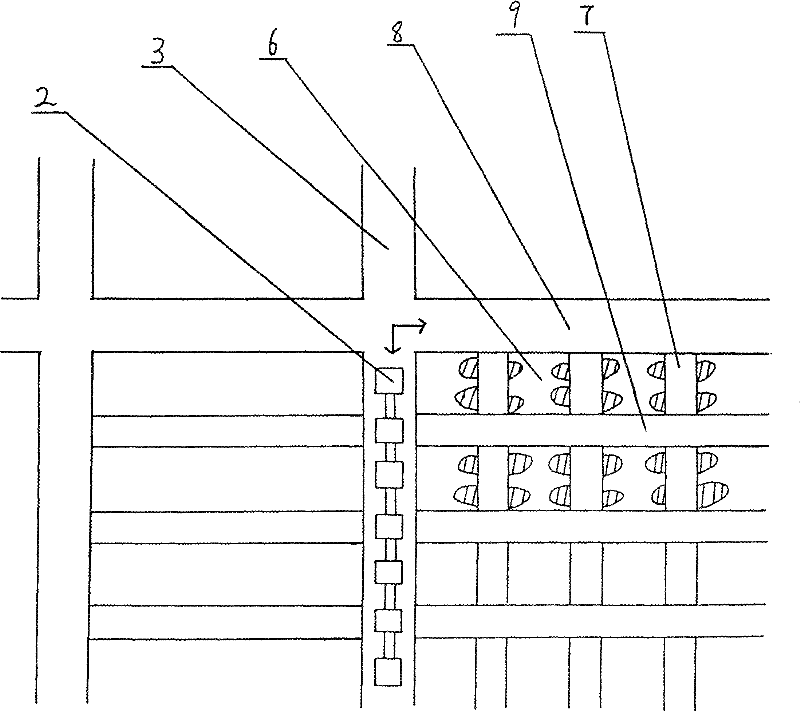

[0011] see figure 1 , drive out the main mine road 8 along the bottom manganese groove, and open a winding mountain roadway 3 intersecting with the main mine roadway every 100 meters along the direction of the manganese groove 5. Rail transport vehicles 2 are installed on the main mine road and the winding mountain roadway. The slot 5 intersects and runs parallel to the main mine road with a circulation lane 9. Mining holes are excavated on both sides of the circulation lane to excavate manganese ore at intervals. A funnel 1 is set at the intersection of the roadway 3 and the circulation lane. Below the funnel is a transport vehicle, and the distance between the funnels is 20 meters The method of mining manganese ore into the circulation lane is: along the direction of the manganese groove, a rock ridge 6 is bidirectionally drilled a mining hole 7, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com