Information-based control and management method for production flow setting and week operation plan arrangement

A technology of operation planning and production process, which is applied in the direction of calculation, data processing applications, instruments, etc., can solve the problems of inability to operate efficiently and transparently, and achieve the effect of improving efficiency, transparency, information control and management methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

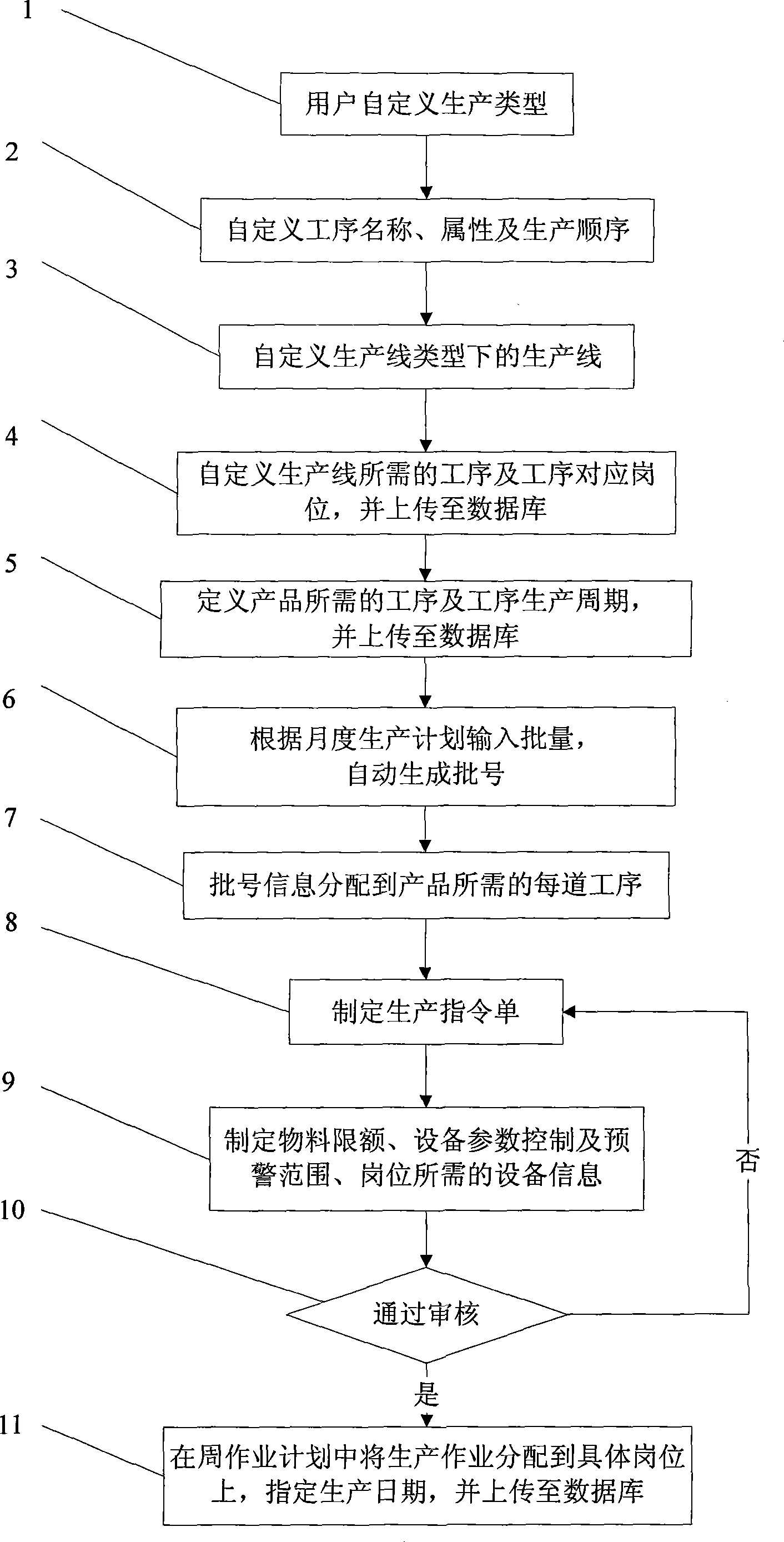

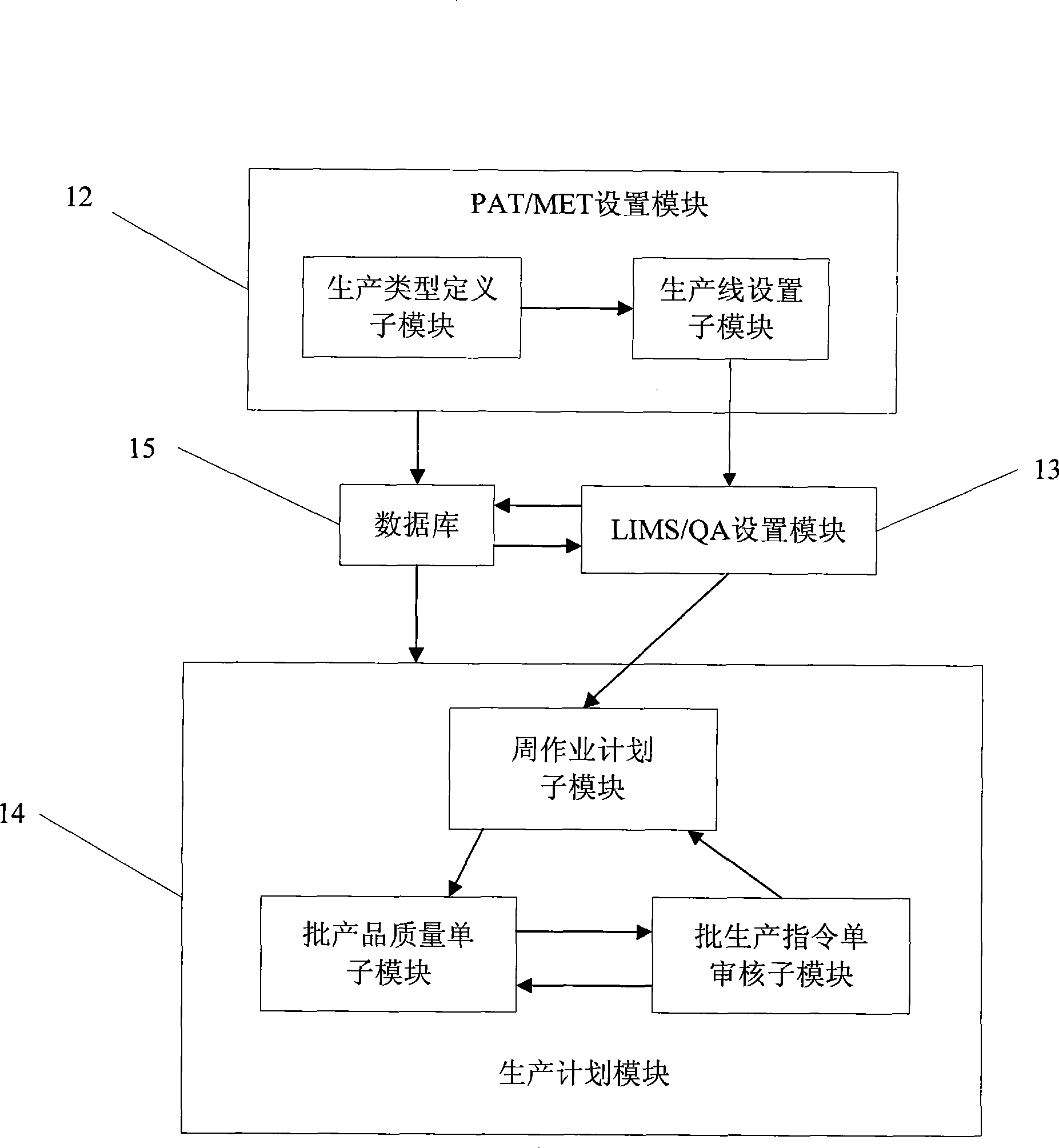

[0020] Such as figure 1 As shown, in the information control and management method of production process setting and weekly operation planning arrangement of the present invention, step 1 is the initial step, and the user defines the production type; in step 2, the user-defined process name, attribute and production sequence ;In step 3, customize the production line under the production line type; in step 4, customize the process required by the production line and the corresponding position of the process, and upload it to the database; in step 5, define the process required for the product and the production process cycle, and upload to the database; in step 6, input the batch according to the monthly production plan, and automatically generate the batch number; in step 7, assign the batch number information to each process required by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com