Judgment method for goods warehouse-out check

A technology of goods and test results, which is applied in the field of warehouse management, can solve problems that affect work efficiency, work efficiency is low, and warehouse managers cannot be found in a short time, so as to improve work efficiency, reduce human errors, and make reasonable judgment methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

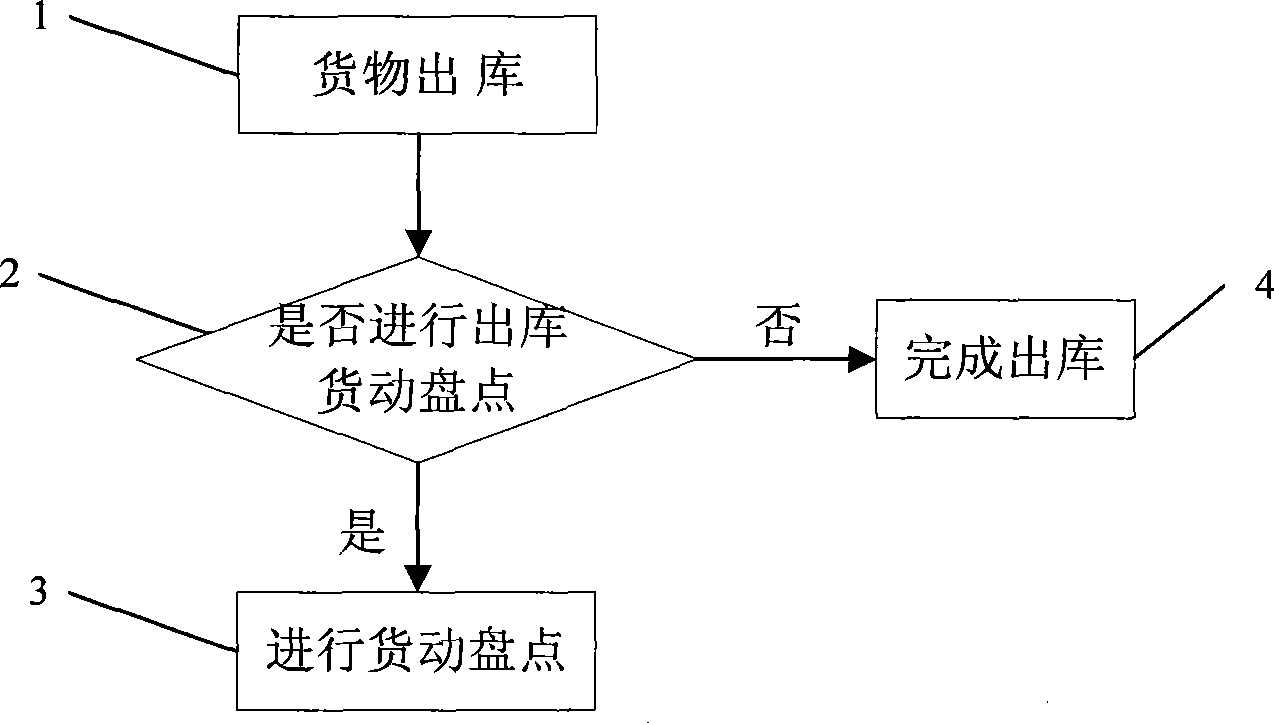

[0013] like figure 1 As shown, in the judging method of the outbound cargo inventory of the present invention, step 1 is the initial step, and the goods are out of the warehouse; Carry out inventory check in step 3, if the detection result is negative, complete delivery in step 4.

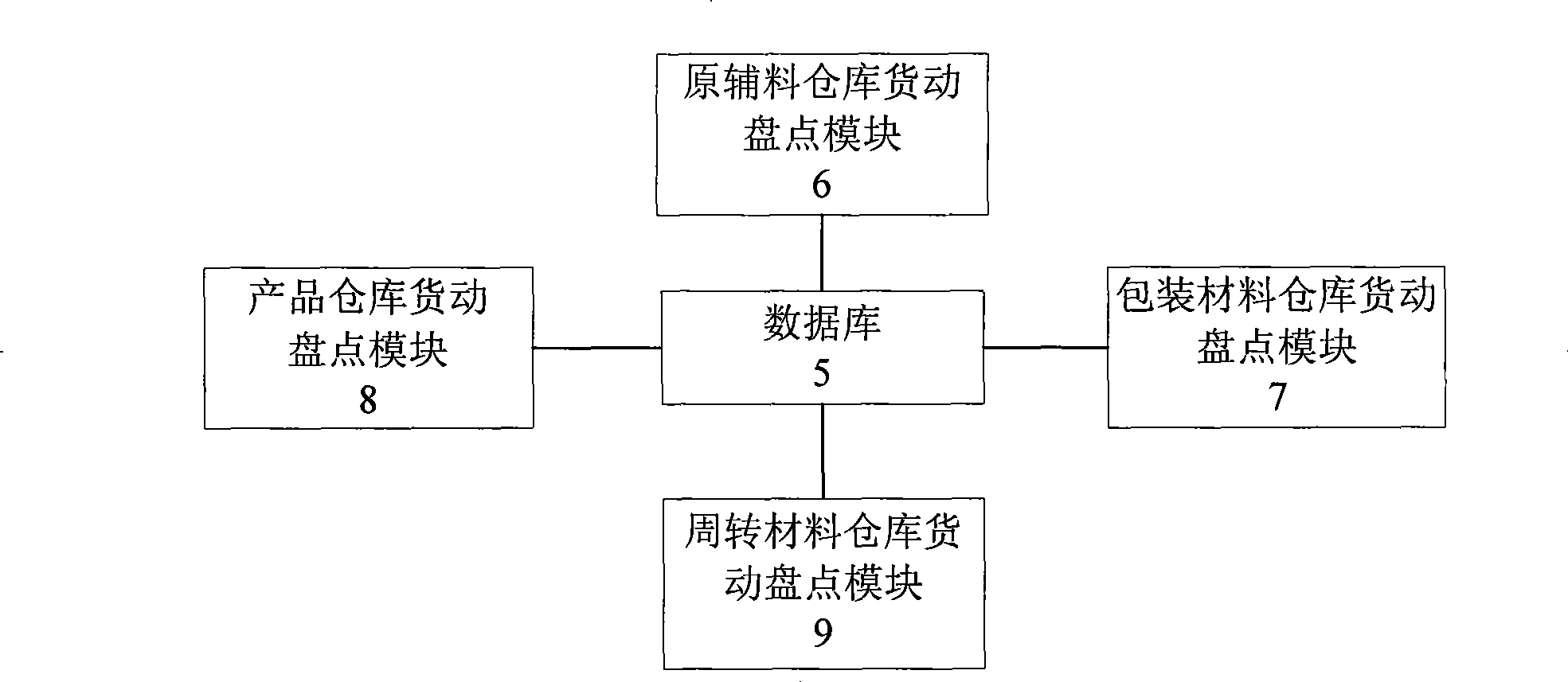

[0014] like figure 2 As shown, the figure 2 It is a structural diagram of the judgment system for outbound goods inventory, and its structure includes a database 5, an inventory module for raw and auxiliary materials warehouse 6, an inventory module for packaging materials warehouse 7, an inventory module for product warehouses 8, and an inventory module for turnover materials. Inventory Module 9. Through the database 5, the movement inventory module 6 of the raw material warehouse, the movement inventory module 7 of the packaging material warehouse, the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com