Judgment method for product warehouse-out quality inspection

A technology for product and quality inspection, applied in instruments, data processing applications, logistics, etc., can solve problems such as adverse effects on drug quality, affecting the production efficiency of pharmaceutical factories, failure to realize automatic control and operation, etc., to achieve reasonable judgment methods and reduce artificial The effect of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

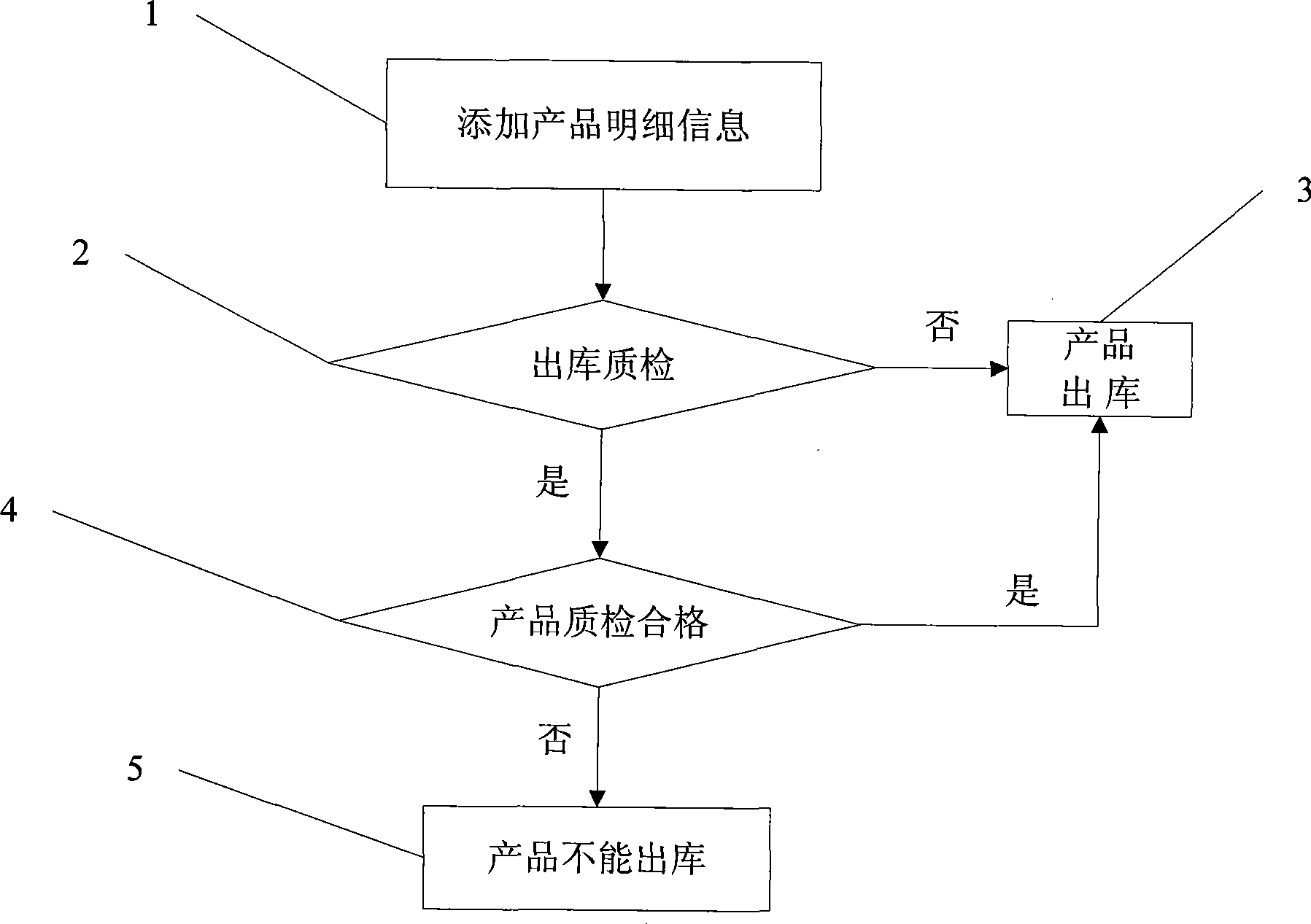

[0014] like figure 1 As shown, in the method for judging the quality inspection of products out of the warehouse, step 1 is the initial step, adding product details; in step 2, check whether the quality inspection of the outbound products, if the detection result is no, go to step 3, if the detection result If yes, go to step 4; in step 3, the product is out of the warehouse; in step 4, check whether the product is qualified for quality inspection, if the test result is yes, then return to step 3, if the test result is no, then go to step 5 ; In step 5, the product cannot be delivered from the warehouse.

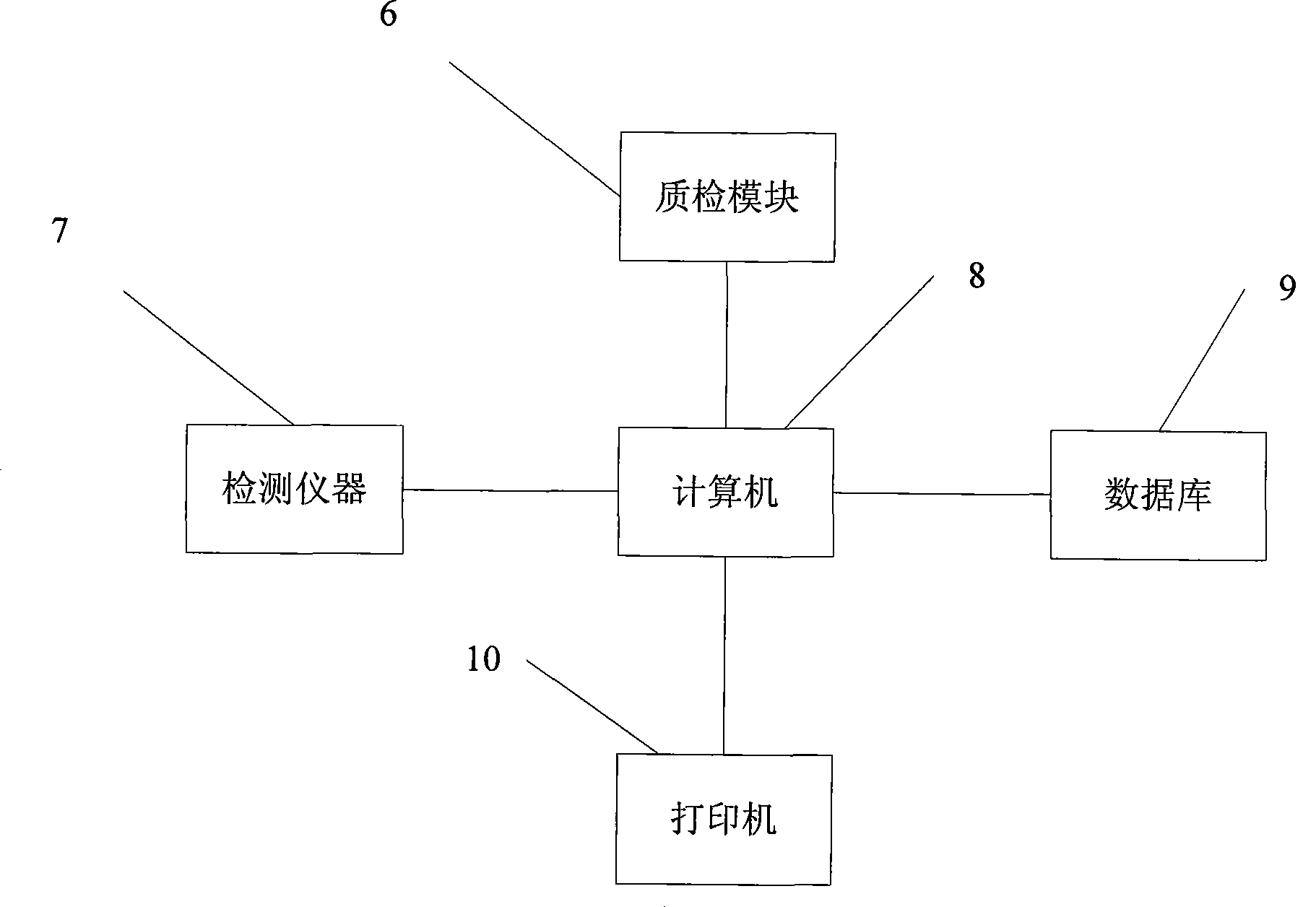

[0015] like figure 2 As shown, the figure 2 It is a schematic diagram of the main structure of the outbound quality inspection judgment system of the present invention, and its structure includes a quality inspection module 6 , a detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com