Method for the production of a single part piston and a piston produced by such a method

An all-in-one, piston technology, applied in the direction of tools, pistons, manufacturing tools, etc. for lathes, can solve problems such as height restrictions, save tool costs, reduce manufacturing costs, and achieve the effect of manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

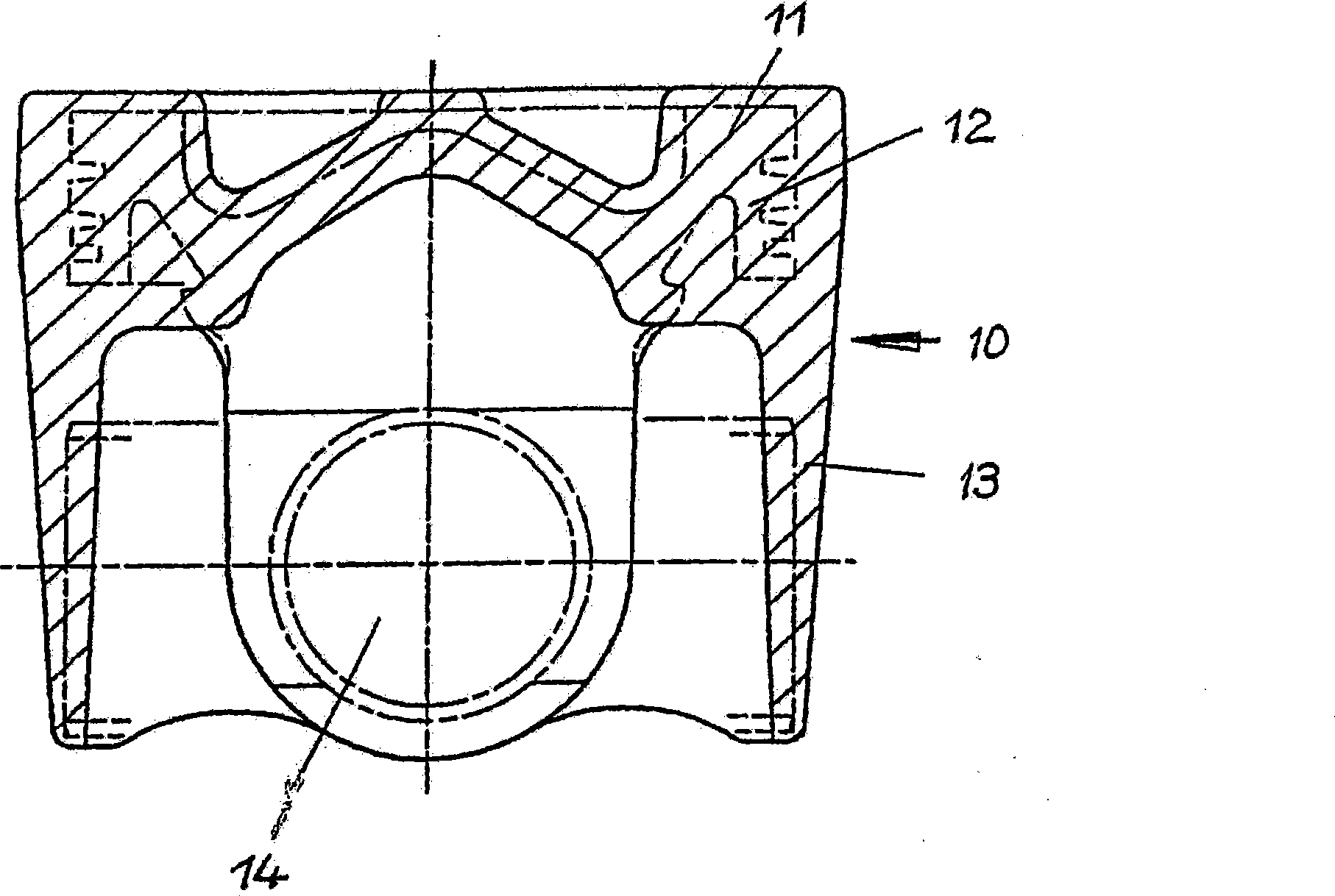

[0016] figure 1 A one-piece forged piston blank 10 is shown, which is produced in the exemplary embodiment according to known forging methods. The profile of the finished piston 20 is indicated by dotted lines. The piston blank 10 comprises a piston crown 11 with a subsequent piston ring band 12, a piston skirt 13 and a piston pin seat 14 added to the piston crown 11, and can be made of forged steel or a light metal alloy, such as aluminum Alloy.

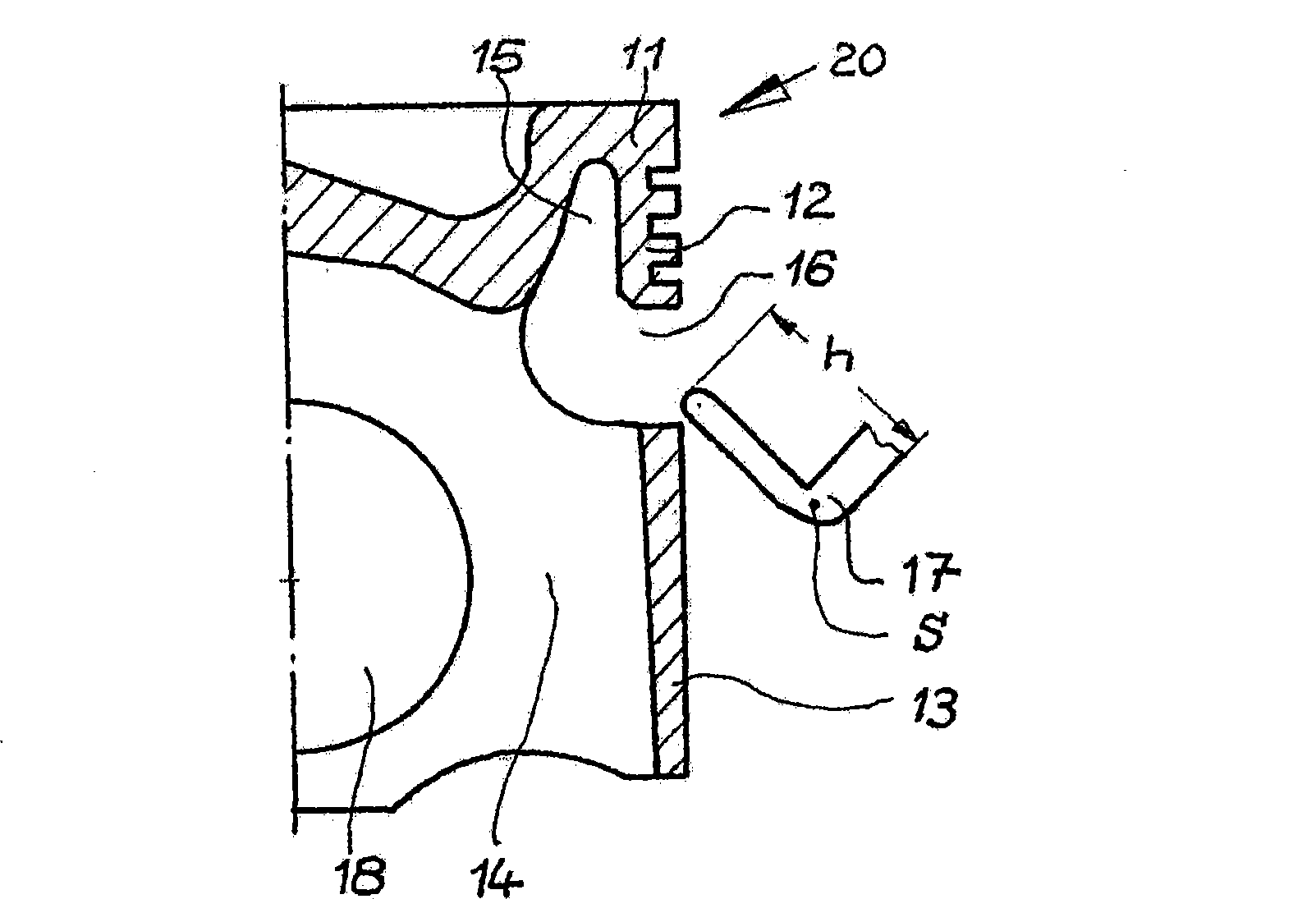

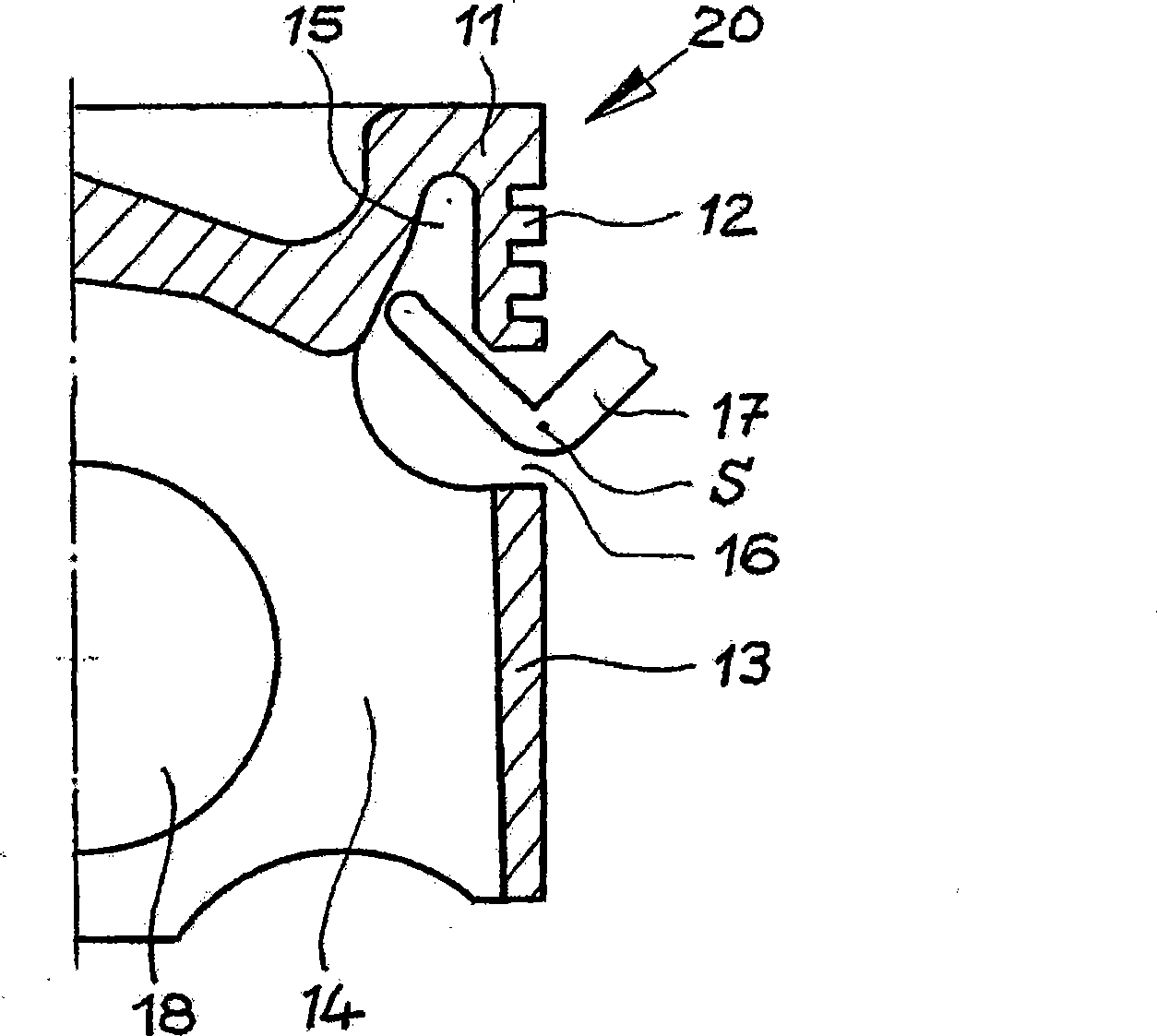

[0017] exist Figures 2 to 6 The method steps for producing the cooling channel 15 in the region of the piston ring 12 according to the invention are shown in .

[0018] In a first method step, the groove 16 is provided in the piston blank 10 by machining (in the exemplary embodiment by turning). The height of the groove 16 must only be such that the tool (in the exemplary embodiment a hook-shaped turning tool 17 ) can be moved in an arcuate swivel motion into the region of the cooling channel 15 to be produced during the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com