Light emitting diode driving circuit

A technology of light-emitting diodes and driving circuits, which is applied in the directions of circuits, electroluminescent light sources, and electric lamp circuit layout, etc., can solve problems such as the reduction of the brightness of LED14

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

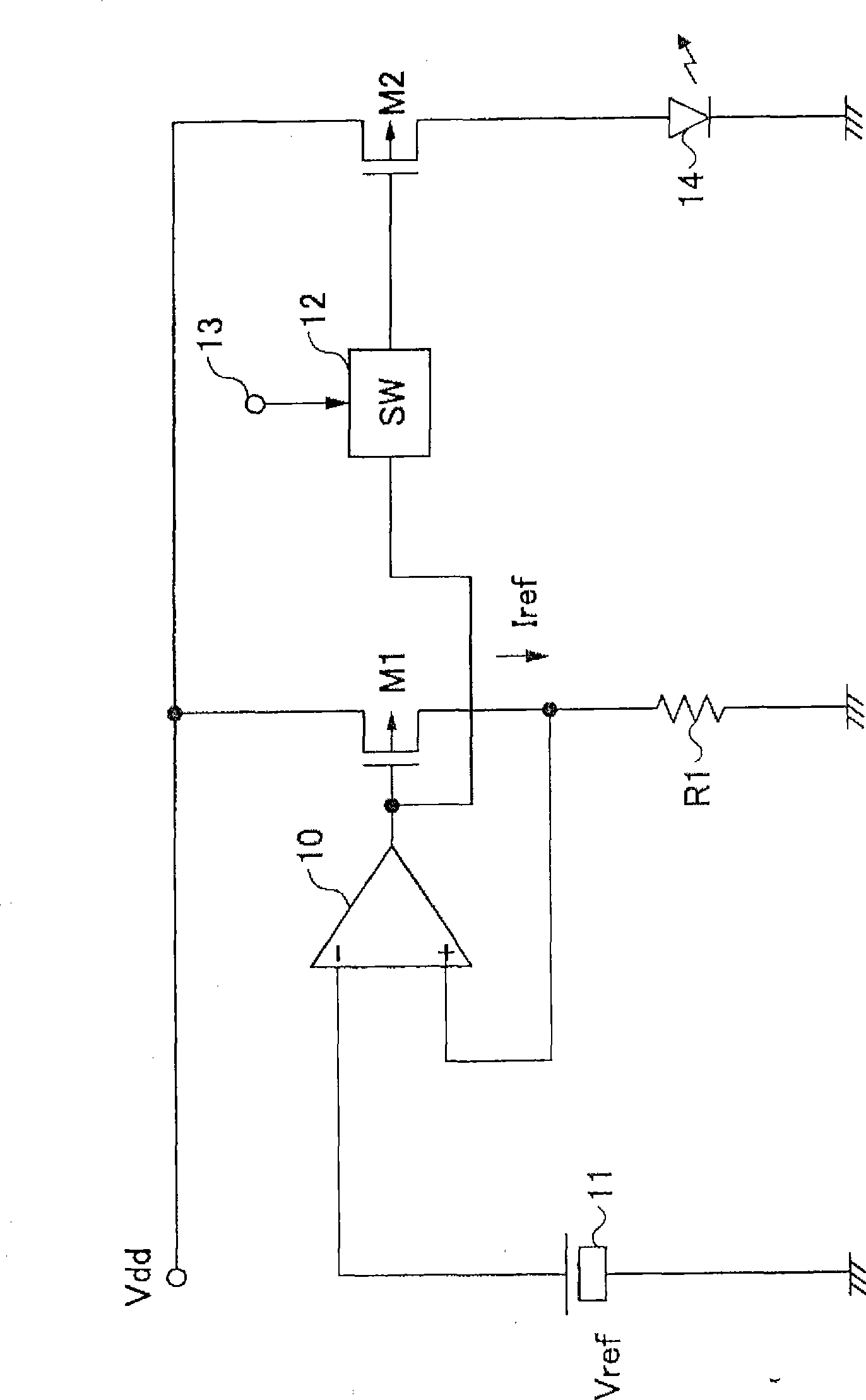

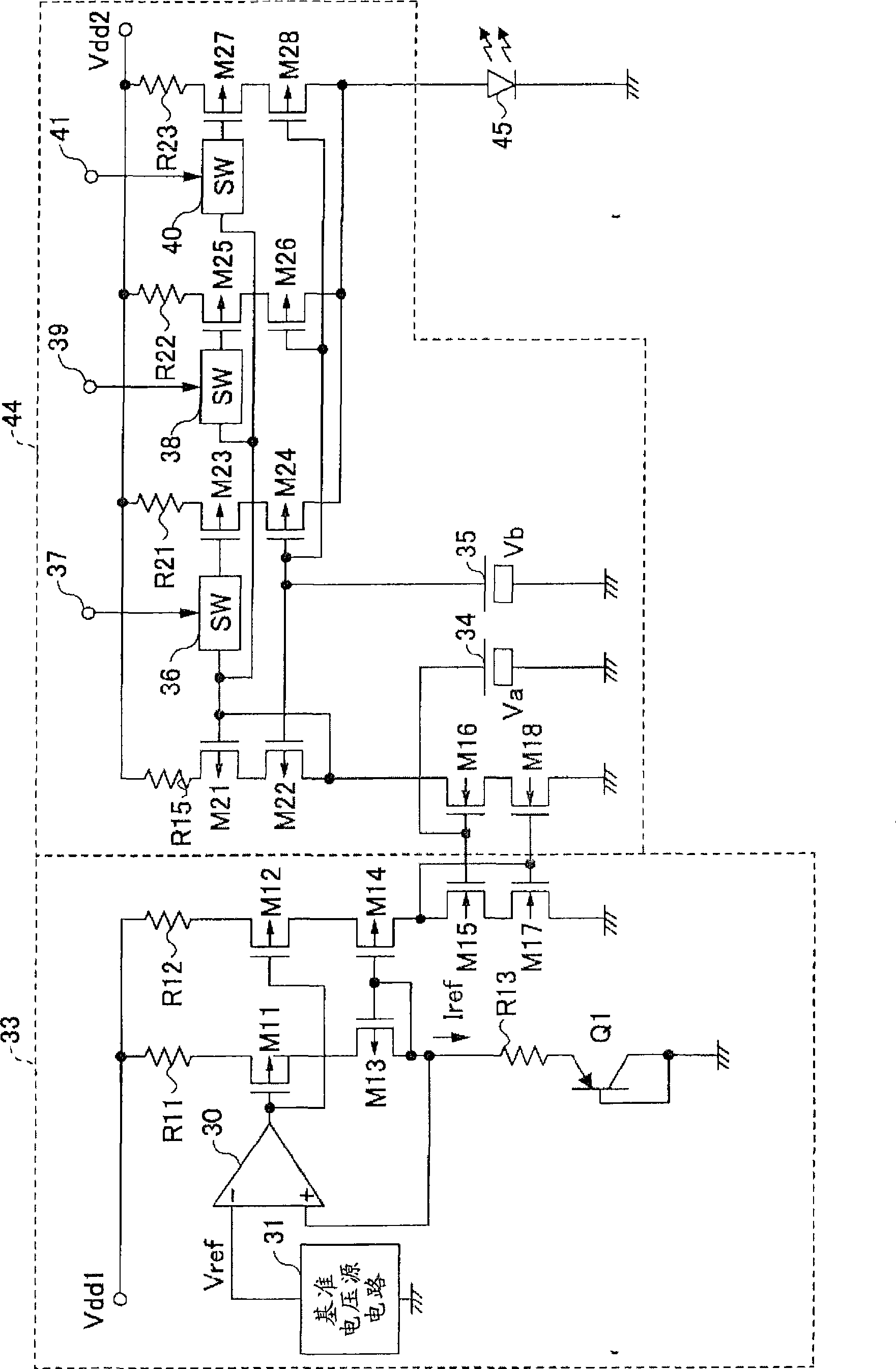

[0039] Embodiments of the present invention will be described below with reference to the drawings.

[0040]

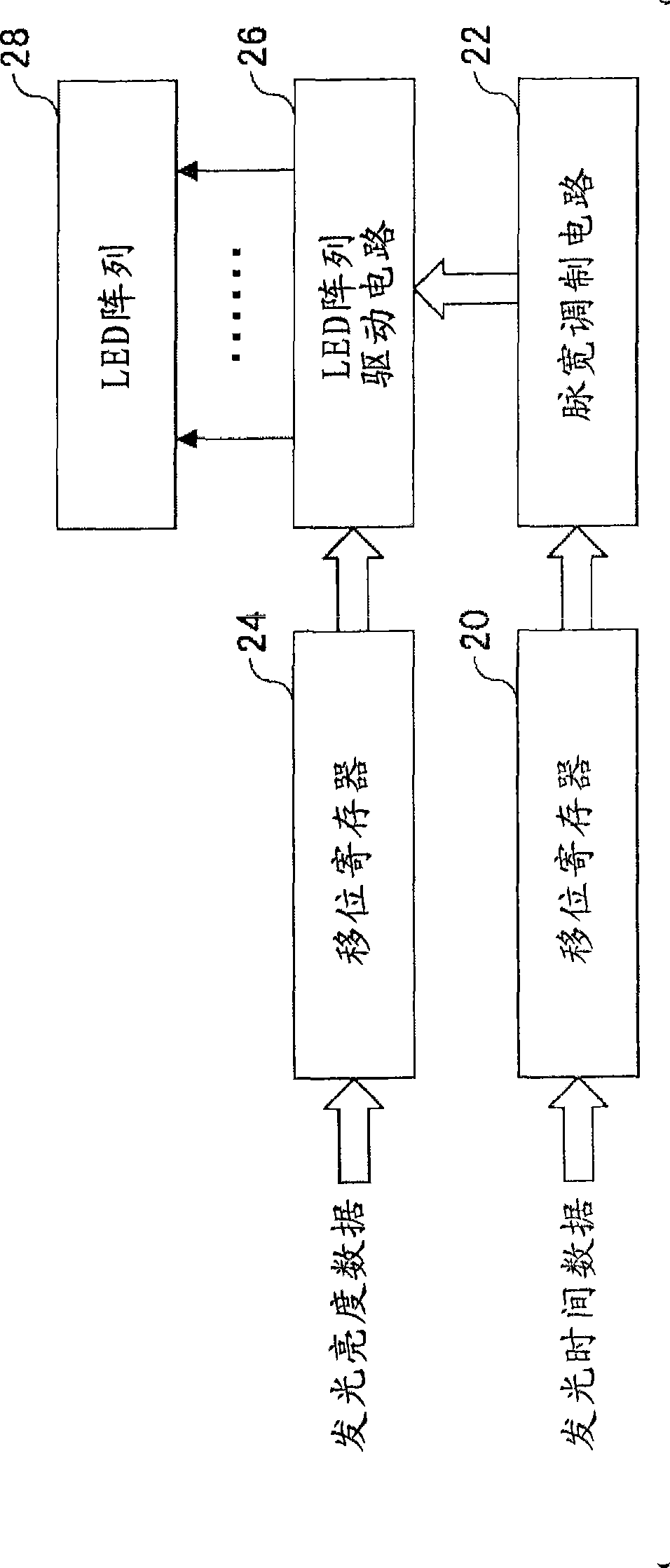

[0041] figure 2 A block diagram showing an embodiment of an LED array device using the light emitting diode driving circuit of the present invention. The LED array device is, for example, a 48-channel structure.

[0042] In this figure, in the shift register 20, 6-bit luminous time data is supplied in time series with, for example, 48 channels for one channel, and after the data is sequentially shifted and latched in the shift register 20, it is It is supplied to the pulse width modulation circuit 22 . The pulse width modulation circuit 22 generates light emission pulses having a pulse width indicated by light emission time data for each channel, and supplies light emission pulses for 48 channels to the LED array drive circuit 26 .

[0043] In the shift register 24, 6-bit luminescence time data is supplied to one channel, for example, in time series of 48 channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com