Multi-station forging and pressing robot for continuous forging

A multi-station, forging technology, applied in the driving device of forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc., can solve the problem of unstable product quality, poor parts consistency, affecting product quality, etc. problems, to achieve the effect of strong promotion value, simple structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

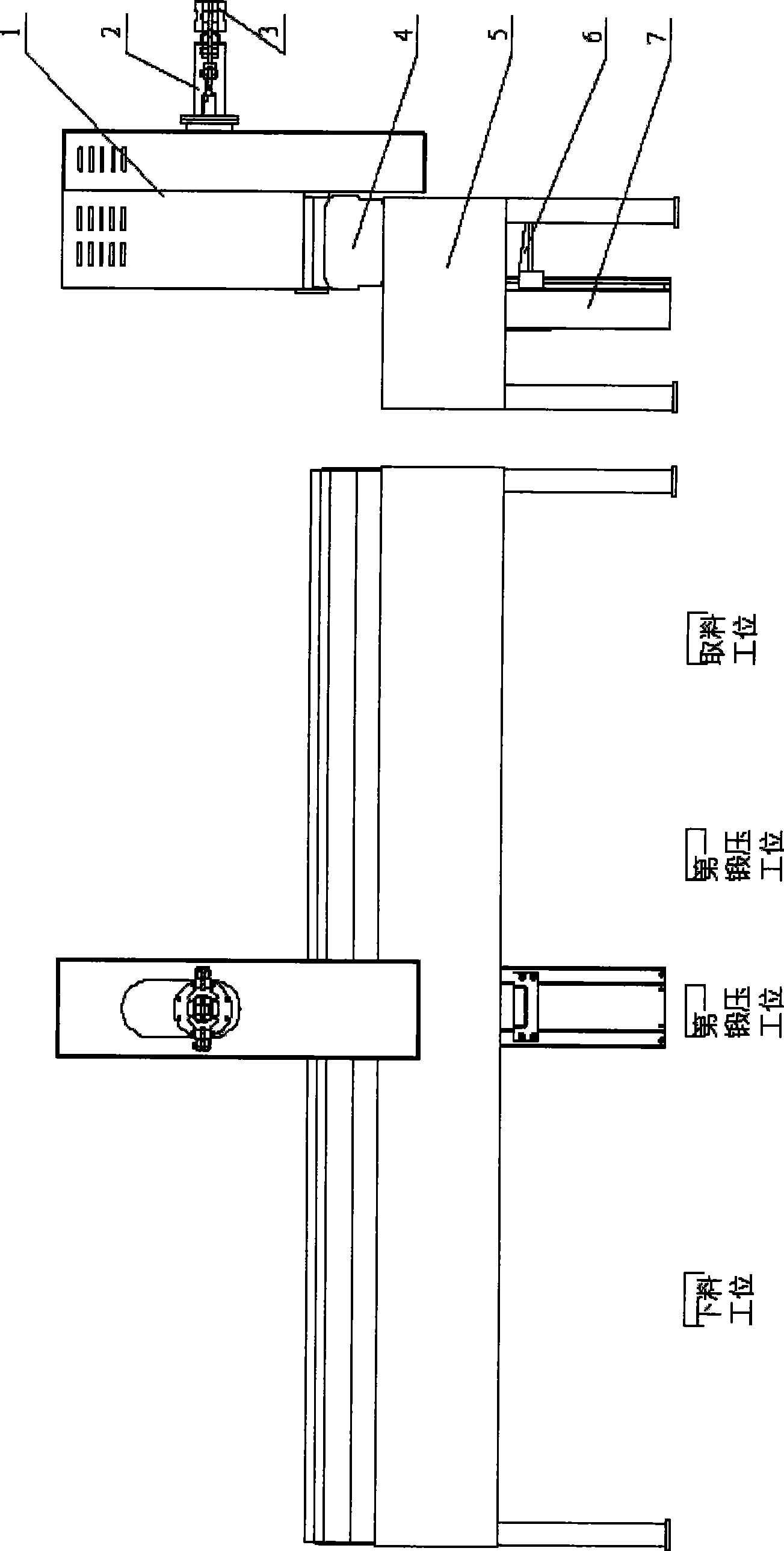

[0018] This embodiment includes a vertical movement mechanism 1, a forging mechanical arm 2, a gripper 3, a left and right movement mechanism 4, a frame 5, a forging equipment control platen 6 and a forging equipment coordination mechanism 7. Left and right moving mechanism 4 is installed on the frame 5, can drive up and down moving mechanism 1, forging mechanical arm 2 and hand claw 3 to move left and right. The up and down moving mechanism 1 is installed on the left and right moving mechanism 4, which can drive the forging mechanical arm 2 and the gripper 3 to move up and down. The forging mechanical arm 2 is installed on the up and down moving mechanism 1, which can drive the claw 3 to move back and forth and to rotate infinitely over 360° along the moving axis. Thus, the claw can realize three degrees of freedom of movement, left and right, up and down, front and back, and a degree of freedom of rotation along the front and rear moving axes. The opening and closing of the...

Embodiment 2

[0020] The difference between this embodiment and Embodiment 1 is that the up and down moving mechanism 1, the forging mechanical arm 2, the gripper 3, the left and right moving mechanism 4 and the frame 5 are still a set, while the forging equipment control platen 6 and the forging equipment coordination mechanism 7 have Multiple sets, the number of sets is the same as the number of forging dies. Each forging die is installed on a single forging equipment, and each set of forging equipment coordinating mechanism 7 and forging equipment control platen 6 coordinate and control the forging equipment on the corresponding station. The equipment coordination mechanism 7 and the forging equipment control platen 6 control all the forging equipment to stop forging. When forging at any forging station, only the forging equipment coordination mechanism 7 and the forging equipment control platen 6 on the station control the corresponding forging equipment for continuous forging. .

Embodiment 3

[0022] In this embodiment, the up and down moving mechanism 1, the forging mechanical arm 2, the gripper 3, the left and right moving mechanism 4 and the frame 5 are still one set, while the forging equipment control platen 6 and the forging equipment coordinating mechanism 7 have multiple sets, and the number of sets is the same as that of the forging equipment. The number of molds is the same. The difference is that some of the forging dies are installed separately on one forging equipment, and some of the dies are shared on one forging equipment, which belongs to the mixed structure of Embodiment 1 and Method 2. When multiple dies are located on the same forging equipment, according to the method The coordination mechanism action of the second mode, when the mold is installed on a forging equipment alone, the coordination mechanism action of the first mode is adopted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com