Multifunctional electric hammer

A multi-functional, electric hammer technology, used in portable impact tools, drilling/drilling equipment, portable drilling rigs, etc., to achieve the effect of compact structure, simple operation and convenient function conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

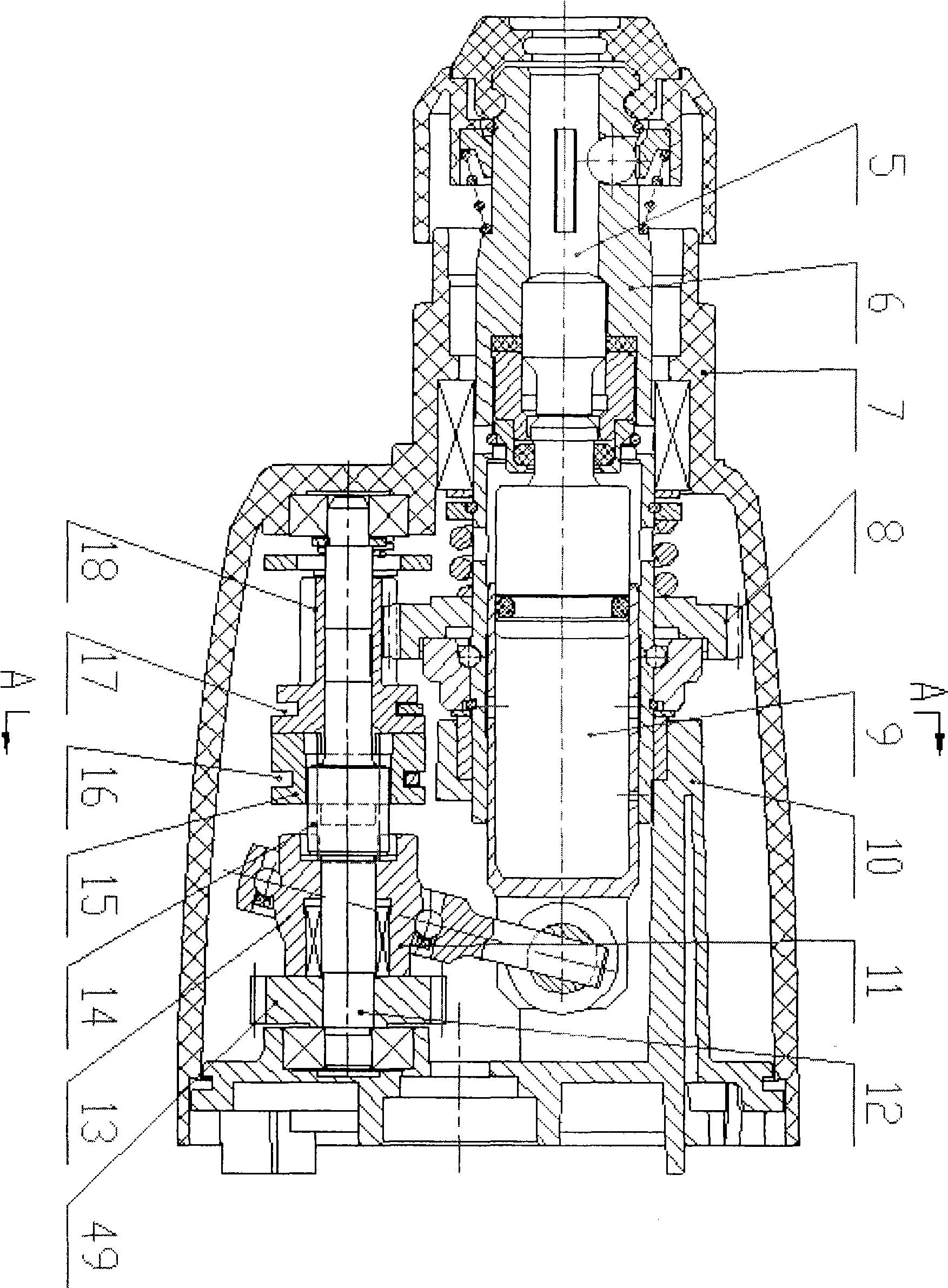

[0026] The present invention described in the embodiment comprises a front end component and a rear end component (this part or the prior art is the same, so not shown); the front end component is a transmission control part, and the rear end component is a power part.

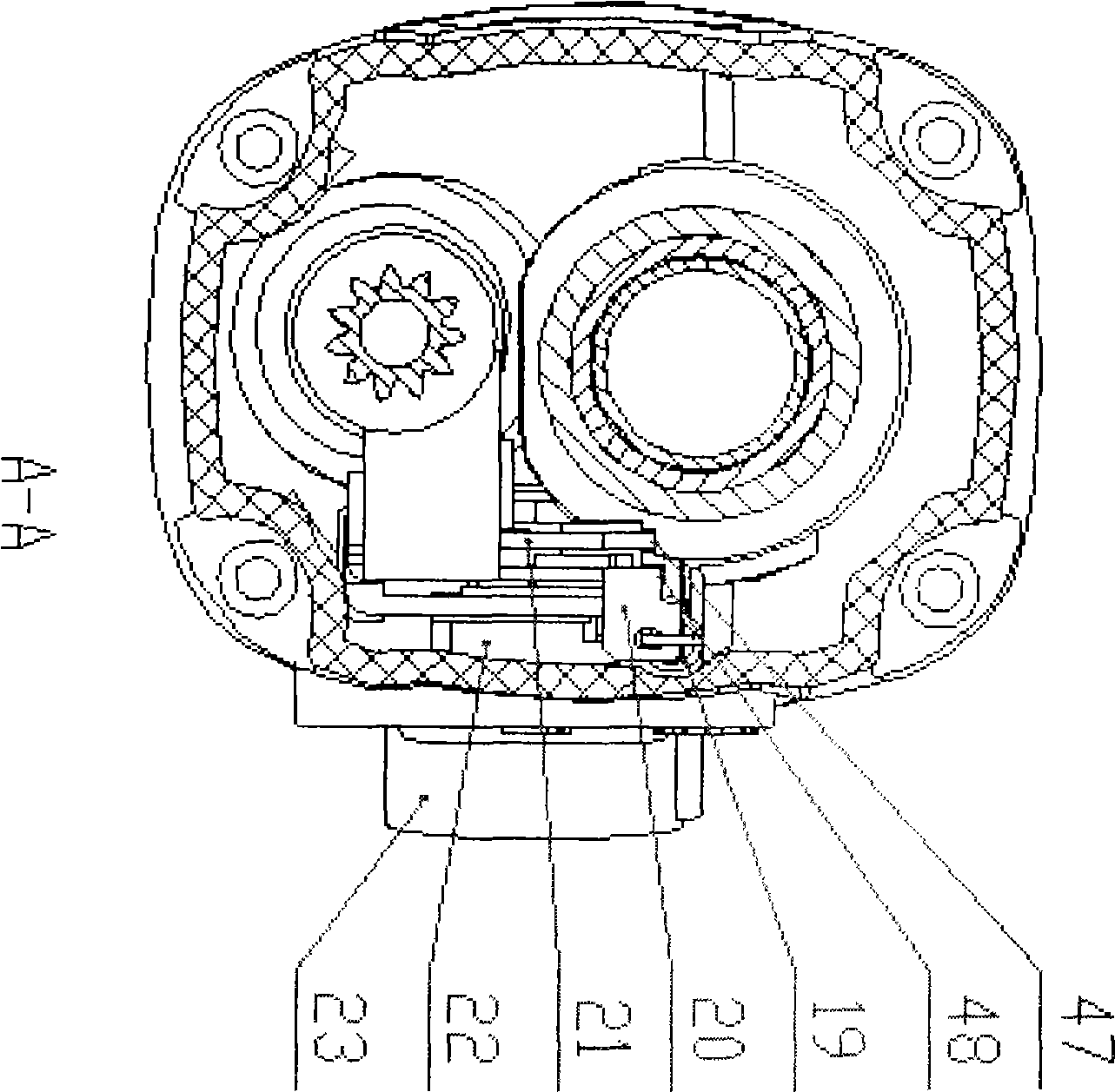

[0027] The front end components include front end housing 7, base 10, drive shaft assembly 11, impact shaft assembly 5, hammer slide 20, drill slide 21, first slide spring 19, second slide spring 19', inner knob 22, outer knob 23, Anti-rotation plate 24 etc., wherein:

[0028] The transmission shaft assembly 11 is mainly composed of the transmission shaft 12, the gear 49 sleeved on the transmission shaft 12 and connected to the power part, the swing rod bearing 13 sleeved on the transmission shaft 12, the axially slidable bearing 13 sleeved on the transmission shaft 12 to connect with the pendu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com