Appliance for removing oil slick on surface of soap

An appliance and oil slick technology, which is applied in the field of kitchen appliances, can solve problems such as affecting soup, affecting the taste of soup, and scalding hands with steam, and achieves the effects of simple structure, avoiding steam scalding, and convenient use by hand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

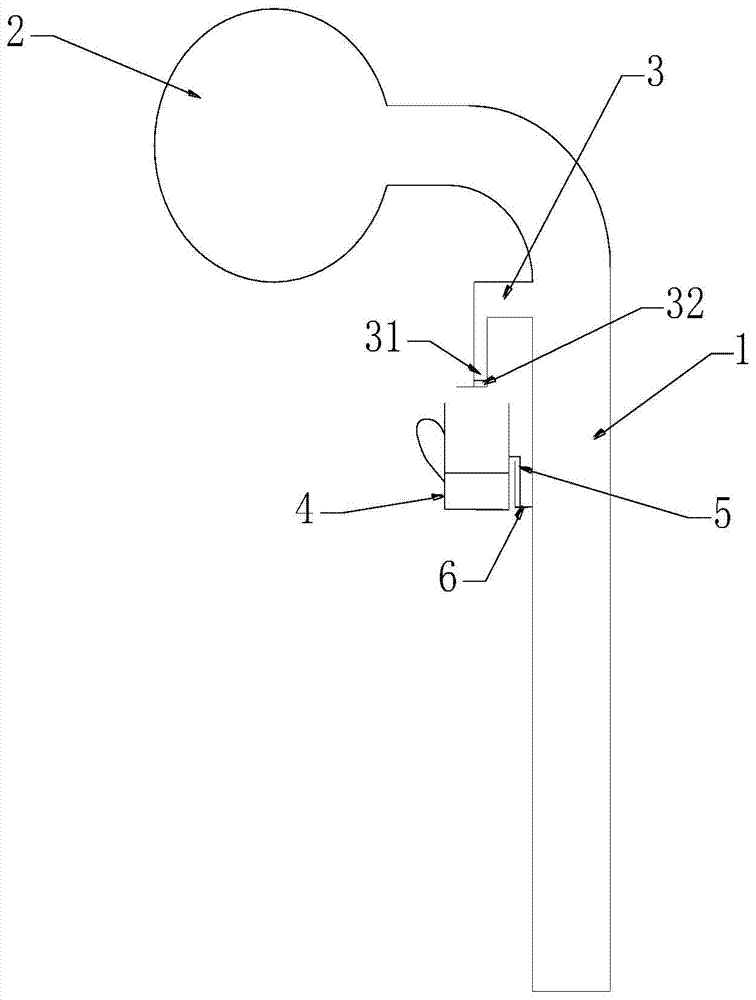

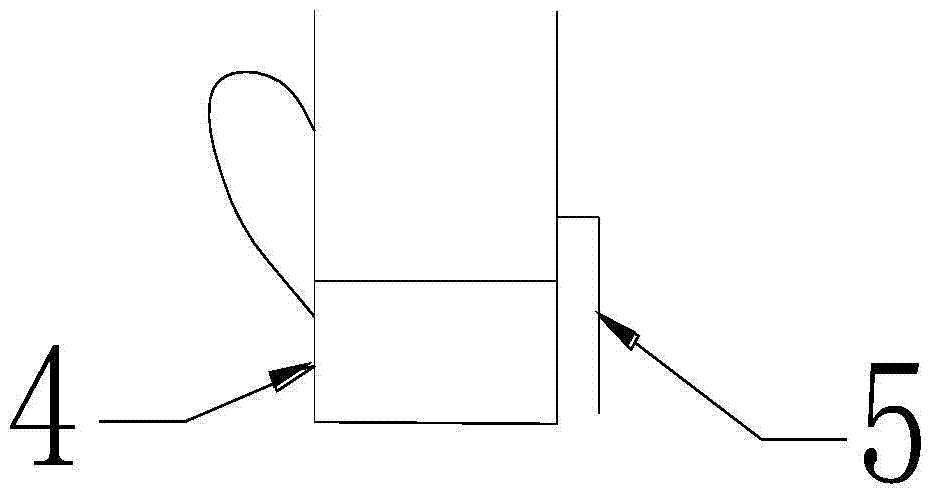

[0014] The present invention will be described in detail below in conjunction with accompanying drawing, as Figure 1-2 Shown:

[0015] A device for removing floating oil on the soup surface of the present invention comprises a transparent pipe 1 and a rubber extruding ball 2, the upper end of the transparent pipe 1 is bent, and the rubber extruding ball 2 is connected with the upper port of the transparent pipe 1, the The lower port of the transparent pipe 1 is the soup inlet. The device has a simple structure. Squeeze the rubber ball and then loosen it slowly. It can suck the slick oil on the surface of the soup into the transparent pipe from the soup inlet, and at the same time suck part of the soup. However, because the specific gravity of the slick oil is smaller than that of water, The floating oil sucked into the transparent pipe is at the upper end of the soup, while the soup is at the lower end, then gently squeeze the rubber extrusion ball to discharge the soup suck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com